4.8 out of 5 Stars on TrustPilot

What Makes Lime Render Eco-Friendly?

When it comes to sustainable construction and renovation, lime render is increasingly recognised as an eco-friendly choice. But why exactly is this ancient building material considered green and sustainable? Let’s delve into some of the key factors that make lime an eco-conscious option for construction.

Low Embodied Energy

Embodied energy is a comprehensive measure that includes all the energy consumed to produce material—right from the extraction of raw resources to manufacturing, transportation, and installation. It’s a crucial parameter to consider when assessing the environmental impact of any building material.

Lower energy manufacturing process

The production of lime render typically involves the heating of limestone to relatively low temperatures (around 800–1,000 degrees Celsius) in a process known as calcination. This is less energy-intensive compared to the production of Portland cement, which often requires temperatures exceeding 1,400 degrees Celsius. Lower temperatures mean less fossil fuel consumption, resulting in fewer carbon dioxide emissions.

Simplified ingredients

Lime render consists of simple, natural components—primarily just lime, water, and natural fibres or aggregates. The straightforward nature of these ingredients typically demands less mechanical processing, further reducing the energy footprint of the material.

Local availability

Limestone, the primary raw material for lime render, is abundant and widely distributed globally. This widespread availability often reduces the transportation distances from quarry to production facilities and ultimately to the construction sites, cutting down on the energy expended for transportation.

Energy-efficient kilns

Advancements in lime production technology, such as the use of more energy-efficient kilns, have further reduced embodied energy. Modern-day lime kilns are designed to capture and recycle heat, thus optimising energy use during production.

Reduced need for additional treatments

The natural properties of lime render, such as its resistance to mould and moisture, often eliminate the need for additional chemical treatments, which can be energy-intensive to produce. This again contributes to a reduced total embodied energy when using lime render in construction.

Eco-friendly Renewable Resource

Abundance of limestone

Limestone, the raw material for lime render, is one of the most abundant resources on Earth. It is found in large quantities in various regions around the world, making it easily accessible. The ample supply ensures that limestone can be used sustainably without exhausting the resource.

Regenerative qualities

Limestone formations are a part of the Earth’s natural geological cycle. They are formed from the skeletal fragments of marine organisms, which accumulate on the ocean floor over millions of years. As these organisms continue to live, die, and accumulate, new limestone deposits are naturally regenerated over geological timescales.

Sustainable quarrying practices

Modern limestone quarrying has become increasingly sustainable, with many operations focusing on minimising their environmental impact. For example, some quarries are engaged in habitat restoration, wherein they rehabilitate the site post-extraction to support local flora and fauna. This focus on sustainability enhances limestone’s status as a renewable resource.

Reduced extraction impact

Compared to other building materials like metals or petrochemical-based products, the extraction of limestone tends to have a lower environmental impact. The process usually involves cutting or blasting relatively shallow pits, which is generally less destructive than, for example, deep mining operations for metals or drilling for oil.

Circular economy and recyclability

Old lime render can be recycled and reused. It can be crushed and returned to the production cycle to create new lime render or other lime-based products. This quality not only reduces waste but also lowers the demand for new raw material extraction, contributing to the concept of a circular economy.

Versatility and substitution

Limestone used in lime render is chemically versatile and can sometimes be substituted by other forms of calcium carbonate, like marble or chalk, depending on the application. This versatility further enhances its status as a renewable resource, as it reduces dependency on a single type of raw material.

Breathability

What does ‘breathability’ mean?

In the context of building materials, breathability refers to the ability to allow the passage of water vapour and air. Lime render is highly breathable due to its porous structure, which means it can absorb and release moisture effectively, thereby helping to regulate humidity levels within a structure.

Natural humidity regulation

The porous nature of lime render means that it can absorb excess moisture from the air when humidity levels are high and release it back when the air is dry. This creates a more stable and comfortable indoor environment, reducing the need for mechanical ventilation and air conditioning systems, which often consume significant amounts of energy.

Prevention of mould and mildew

The breathability of lime render helps to wick away moisture from building structures, thereby reducing the likelihood of mould and mildew formation. These fungal growths not only pose health risks but also often necessitate repairs and the use of chemical treatments, which can be environmentally damaging.

Compatibility with other breathable materials

Lime render works well with other breathable building materials, such as wood and certain types of natural insulation, creating a holistic, breathable building envelope. This further aids in creating a healthy indoor climate, cutting down on the need for electronic climate control and thereby reducing energy consumption.

Improved indoor air quality

Lime render’s ability to absorb and release moisture can also help to filter and purify indoor air. It can absorb pollutants and odours, contributing to a healthier indoor environment. This can sometimes reduce the need for air purifiers or other mechanical means of improving air quality, which typically consumes electricity.

Preservation of building integrity

In older buildings, particularly those with solid walls without a damp-proof course, breathability is crucial to allow moisture to escape. Lime render is often used in the renovation of historic buildings for this reason. Allowing walls to breathe, helps to maintain the integrity of the building, reducing the need for more intrusive and potentially environmentally unfriendly repair work.

Energy efficiency and comfort

Breathable materials like lime render contribute to a building’s thermal mass, helping to regulate indoor temperatures naturally. This can mean that less energy is required for heating and cooling, reducing a building’s overall carbon footprint.

Longevity and Durability

Material composition and structure

Lime render is composed of calcium carbonate, which has a crystalline structure that provides excellent mechanical strength and durability. Unlike other materials that may degrade rapidly due to environmental exposure, lime renders age gracefully and can even improve in quality over time.

Adaptability to seasonal changes

In regions with significant seasonal temperature variations, building materials are often subject to cycles of freezing and thawing, which can lead to rapid degradation. Lime render’s natural flexibility allows it to adapt to these changes without cracking, thus extending its usable life.

Resistance to chemical deterioration

Lime is highly alkaline, which makes it resistant to many types of chemical decay, including corrosion and acid rain. This chemical stability means that it won’t break down as quickly as other materials when exposed to harsh environmental conditions.

Incremental repair potential

In the unlikely event that lime render does require some repair, it is often possible to do so incrementally. Damaged or worn areas can be re-rendered without necessarily having to replace the entire surface. This selective repair capability is not only cost-effective but also less resource-intensive, fitting well with sustainable construction principles.

Heritage and cultural longevity

Because lime render has been used for centuries in various types of buildings, its long-term performance is well-documented. Many historical buildings rendered with lime have stood the test of time and weathered various environmental conditions, demonstrating the material’s longevity and long-term durability.

Lower lifecycle impact

When considering the environmental impact of any building material, it is important to look at its entire lifecycle. The durability and longevity of lime render mean that over its entire lifespan, its cumulative environmental impact is likely to be much lower than materials that require frequent replacement or extensive maintenance.

Cost-effectiveness over time

Although the initial costs of lime render may sometimes be higher than synthetic alternatives, the durability and low maintenance requirements often make it more cost-effective in the long run. When you factor in the reduced need for replacement and repairs, the financial outlay over the material’s lifecycle is often less, making it an economically sustainable choice as well.

Contribution to building integrity

Long-lasting materials like lime render help to extend the overall lifespan of the buildings they are used on. By enhancing the durability of the entire structure, they reduce the likelihood of premature building obsolescence, thereby minimising waste and the need for new construction materials.

Eco-friendly biodegradability

Natural origin

One of the key aspects of lime render’s biodegradability is its natural origin. Lime is essentially calcium carbonate, a naturally occurring compound derived from limestone. Unlike synthetic or petroleum-based materials, lime is compatible with the natural environment, which makes it inherently biodegradable.

No harmful byproducts

When lime render eventually breaks down, it returns to its original form of calcium carbonate, a naturally occurring compound that poses no harm to the environment. This is in contrast to many synthetic materials, which can release toxic substances or microplastics as they degrade.

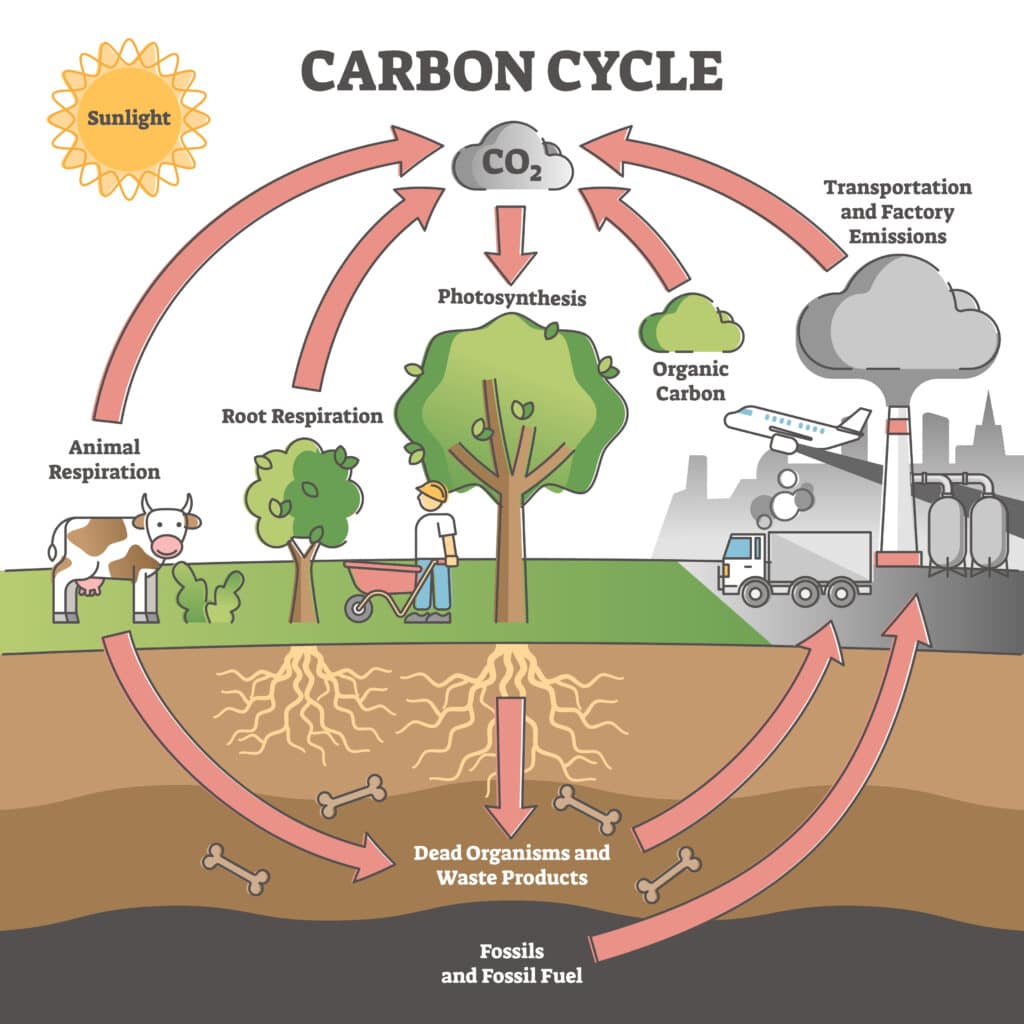

Closed carbon cycle

The process of producing lime involves releasing carbon dioxide (CO2) into the atmosphere, but this is partially re-absorbed over time as the material cures and carbonates. This helps to create a closed carbon cycle, which is beneficial for the environment. Once the lime render is returned to nature, it continues this cycle, breaking down without contributing additional CO2 to the atmosphere.

Landfill impact

If lime render is removed during a renovation or building demolition, its biodegradable nature means that it will break down more easily in landfill conditions compared to synthetic materials. Its decomposition doesn’t release harmful greenhouse gases like methane, which is often the case with other building materials like certain insulating foams or plastics.

Soil neutralisation

Interestingly, lime has been used for centuries in agriculture to neutralise acidic soils. When lime renders biodegrade, they have the potential to contribute to soil health rather than damaging it. This is yet another way in which its biodegradability adds environmental value.

Energy recovery

In some cases, lime render can also be recycled through a process known as “energy recovery,” where the material is burned to produce energy. Though this isn’t biodegradation in a traditional sense, it is another eco-friendly avenue for the material at the end of its life.

Complementing a circular economy

In the broader context of sustainable construction, lime render’s biodegradability fits well within the idea of a circular economy. In a circular economy, products and materials are recycled, reused, or returned to the natural environment in a way that is as sustainable as possible. Lime render’s biodegradable nature makes it a strong candidate for this kind of system, adding yet another layer to its eco-friendly profile.

Eco-friendly thermal insulation

Natural thermal mass

Lime render possesses excellent thermal mass, meaning it has the capacity to store heat energy. This natural characteristic allows buildings to remain cooler in the summer and retain heat in the winter. By acting as a thermal buffer, lime render reduces the need for artificial heating and cooling systems, thereby lowering energy consumption and the associated carbon emissions.

Energy efficiency

The thermal mass of lime render aids in creating an energy-efficient building envelope. The material’s ability to absorb and slowly release heat contributes to stabilising indoor temperatures. This, in turn, reduces the burden on HVAC systems and can result in lower energy bills, a win-win for both the environment and the homeowner.

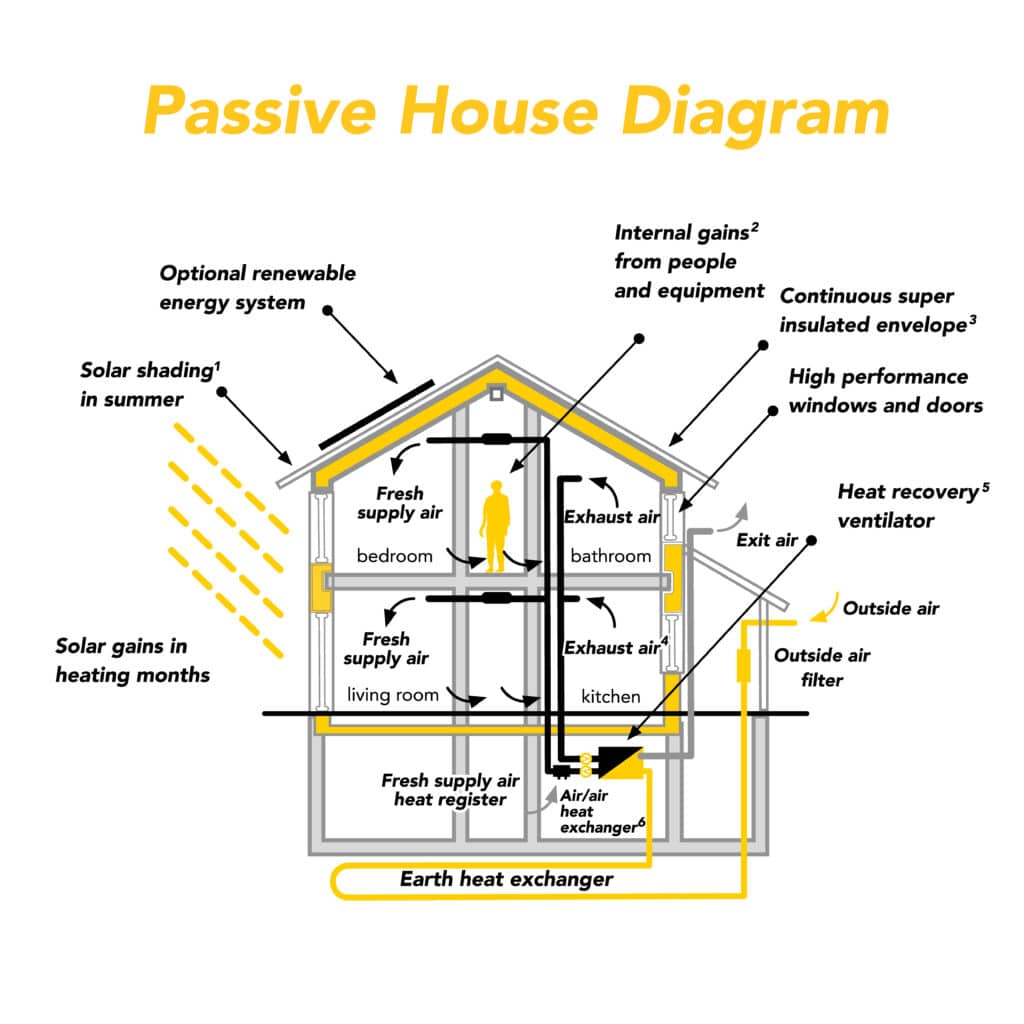

Passive Solar Design

Lime render complements passive solar design principles, where building orientation, window placement, and material choices combine to harness or mitigate the sun’s energy naturally. When used in such designs, lime render can further enhance a building’s thermal performance, reducing its overall environmental impact.

Reducing the Heat Island effect

Urban areas are prone to the ‘heat island’ effect. Concentrated human activity and building materials like concrete and asphalt cause localised temperature increases. Lime render, with its natural thermal properties, can help mitigate this effect. Its lighter colour also tends to reflect more heat, adding to its cooling benefits.

Low conductivity

Lime render has relatively low thermal conductivity compared to materials like cement. This means it is less likely to transfer heat between the interior and exterior of a building, thereby acting as a natural insulator. This is particularly beneficial in climates with significant temperature fluctuations, helping to maintain a consistent indoor temperature.

Breathability and insulation

As mentioned earlier, lime render is breathable, allowing moisture to evaporate quickly. This quality is crucial for thermal insulation as well because moisture within walls can significantly degrade a material’s insulating properties. By allowing moisture to escape, lime render maintains its insulating capability.

Longevity and sustainable comfort

The long-lasting nature of lime render means that its thermal benefits can be enjoyed for generations without the need for replacement. This extended lifespan minimises resource use and waste, contributing to sustainable comfort and long-term energy savings.

Complementing other eco-friendly materials

Lime render works well with other eco-friendly insulating materials like hemp, wood fibre, and sheep’s wool. When used together, these materials can create a highly energy-efficient and sustainable building envelope.

Versatility

A broad range of applications

One of the main benefits of lime render is its versatility in application. Whether it’s for internal walls, external facades, historic restorations, or new builds, lime render can be effectively used. This adaptability reduces the need for multiple different materials, simplifying supply chains and potentially reducing waste.

Aesthetic versatility

Lime render isn’t just functionally versatile; it’s also aesthetically so. It can be finished in a variety of textures and can be tinted with natural pigments. This eliminates the need for additional paints and finishes, many of which can contain harmful chemicals and have a short lifespan, requiring frequent re-application.

Mix flexibility

Lime render can be mixed with various natural fibres and aggregates, such as hemp or flax, to alter its properties. This makes it a highly customisable material that can be tailored to meet specific thermal, acoustic, or aesthetic requirements. Such flexibility reduces the need for synthetic additives or other, less sustainable materials.

Compatibility with various substrates

Lime render can adhere to a wide variety of substrates. This makes it highly versatile in both new constructions and renovations, reducing the need for synthetic primers or bonding agents that might have a higher environmental impact.

Heritage and modern use

The adaptability of lime render makes it an ideal choice for a wide range of building types and ages. For historic buildings, it’s often the go-to material due to its compatibility with older construction techniques. In modern architecture, its sustainable and functional attributes make it increasingly popular, demonstrating its time-spanning versatility.

Easy repairs and modifications

If a wall with lime render needs to be altered or repaired, the process is generally simpler and less invasive than with synthetic materials. This ease of modification helps to prolong the life of the building. It also minimises the use of additional materials, contributing to lime render’s overall sustainability.

Low technical barriers

The application of lime render does not require specialised equipment or complex techniques. This lowers the technical barriers for its use, making it accessible for small-scale, local builders, thereby reducing the need for long supply chains and the associated environmental impact.

Integration in Eco-Friendly building designs

Because lime render pairs well with other eco-friendly building practices and materials—like straw bales, wooden frames, and natural insulations—it’s frequently included in comprehensive sustainable building designs. Its versatility enhances its compatibility with a broad spectrum of eco-friendly construction practices.

Facebook

Twitter

LinkedIn

Your cart

Trade Account Login

We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. By clicking “Accept All”, you consent to the use of ALL the cookies. However, you may visit "Cookie Settings" to provide personalised consent.

Manage consent

Privacy Overview

This website uses cookies to improve your experience while you navigate through the website. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. We also use third-party cookies that help us analyze and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may affect your browsing experience.

Necessary cookies are absolutely essential for the website to function properly. These cookies ensure basic functionalities and security features of the website, anonymously.

| Cookie | Duration | Description |

|---|---|---|

| __stripe_mid | 1 year | This cookie is set by Stripe payment gateway. This cookie is used to enable payment on the website without storing any patment information on a server. |

| __stripe_sid | 30 minutes | This cookie is set by Stripe payment gateway. This cookie is used to enable payment on the website without storing any patment information on a server. |

| _GRECAPTCHA | 5 months 27 days | This cookie is set by the Google recaptcha service to identify bots to protect the website against malicious spam attacks. |

| apbct_cookies_test | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_page_hits | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_prev_referer | session | Functional cookie placed by CleanTalk Spam Protect to store referring IDs and prevent unauthorized spam from being sent from the website. |

| apbct_site_landing_ts | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_site_referer | 3 days | This cookie is placed by CleanTalk Spam Protect to prevent spam and to store the referrer page address which led the user to the website. |

| apbct_timestamp | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_urls | 3 days | This cookie is placed by CleanTalk Spam Protect to prevent spam and to store the addresses (urls) visited on the website. |

| AWSALBCORS | 7 days | This cookie is managed by Amazon Web Services and is used for load balancing. |

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| ct_checkjs | session | CleanTalk–Used to prevent spam on our comments and forms and acts as a complete anti-spam solution and firewall for this site. |

| ct_fkp_timestamp | session | CleanTalk sets this cookie to prevent spam on the site's comments/forms, and to act as a complete anti-spam solution and firewall for the site. |

| ct_pointer_data | session | CleanTalk sets this cookie to prevent spam on the site's comments/forms, and to act as a complete anti-spam solution and firewall for the site. |

| ct_ps_timestamp | session | CleanTalk sets this cookie to prevent spam on the site's comments/forms, and to act as a complete anti-spam solution and firewall for the site. |

| ct_sfw_pass_key | 1 month | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| ct_timezone | session | CleanTalk–Used to prevent spam on our comments and forms and acts as a complete anti-spam solution and firewall for this site. |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features.

| Cookie | Duration | Description |

|---|---|---|

| __zlcmid | 1 year | This cookie is used by Zendesk live chat and is used to store the live chat ID. |

| bcookie | 2 years | LinkedIn sets this cookie from LinkedIn share buttons and ad tags to recognize browser ID. |

| bscookie | 2 years | LinkedIn sets this cookie to store performed actions on the website. |

| lang | session | LinkedIn sets this cookie to remember a user's language setting. |

| lidc | 1 day | LinkedIn sets the lidc cookie to facilitate data center selection. |

| UserMatchHistory | 1 month | LinkedIn sets this cookie for LinkedIn Ads ID syncing. |

Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.

| Cookie | Duration | Description |

|---|---|---|

| __utma | 2 years | This cookie is set by Google Analytics and is used to distinguish users and sessions. The cookie is created when the JavaScript library executes and there are no existing __utma cookies. The cookie is updated every time data is sent to Google Analytics. |

| __utmb | 30 minutes | Google Analytics sets this cookie, to determine new sessions/visits. __utmb cookie is created when the JavaScript library executes and there are no existing __utma cookies. It is updated every time data is sent to Google Analytics. |

| __utmc | session | The cookie is set by Google Analytics and is deleted when the user closes the browser. It is used to enable interoperability with urchin.js, which is an older version of Google Analytics and is used in conjunction with the __utmb cookie to determine new sessions/visits. |

| __utmt | 10 minutes | Google Analytics sets this cookie to inhibit request rate. |

| __utmv | 2 years | The __utmv cookie is set on the user's device, to enable Google Analytics to classify the visitor. |

| __utmz | 6 months | Google Analytics sets this cookie to store the traffic source or campaign by which the visitor reached the site. |

| sib_cuid | 6 months | Purechat uses this cookie to send data to purechat.com, to connect visitors to the reservation team and track visitors to stay on portal. |

| SRM_B | 1 year 24 days | Used by Microsoft Advertising as a unique ID for visitors. |

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc.

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _gat_gtag_UA_61069204_2 | 1 minute | Set by Google to distinguish users. |

| _gat_UA-61069204-2 | 1 minute | A variation of the _gat cookie set by Google Analytics and Google Tag Manager to allow website owners to track visitor behaviour and measure site performance. The pattern element in the name contains the unique identity number of the account or website it relates to. |

| _gcl_au | 3 months | Provided by Google Tag Manager to experiment advertisement efficiency of websites using their services. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| _uetsid | 1 day | This cookies are used to collect analytical information about how visitors use the website. This information is used to compile report and improve site. |

| CONSENT | 2 years | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. These cookies track visitors across websites and collect information to provide customized ads.

| Cookie | Duration | Description |

|---|---|---|

| _fbp | 3 months | This cookie is set by Facebook to display advertisements when either on Facebook or on a digital platform powered by Facebook advertising, after visiting the website. |

| ANONCHK | 10 minutes | The ANONCHK cookie, set by Bing, is used to store a user's session ID and also verify the clicks from ads on the Bing search engine. The cookie helps in reporting and personalization as well. |

| fr | 3 months | Facebook sets this cookie to show relevant advertisements to users by tracking user behaviour across the web, on sites that have Facebook pixel or Facebook social plugin. |

| MUID | 1 year 24 days | Bing sets this cookie to recognize unique web browsers visiting Microsoft sites. This cookie is used for advertising, site analytics, and other operations. |

| NID | 6 months | NID cookie, set by Google, is used for advertising purposes; to limit the number of times the user sees an ad, to mute unwanted ads, and to measure the effectiveness of ads. |

| test_cookie | 15 minutes | The test_cookie is set by doubleclick.net and is used to determine if the user's browser supports cookies. |

| uuid | 6 months | MediaMath sets this cookie to avoid the same ads from being shown repeatedly and for relevant advertising. |

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt-remote-device-id | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt.innertube::nextId | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |

| yt.innertube::requests | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |

Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet.

| Cookie | Duration | Description |

|---|---|---|

| _clck | 1 year | No description |

| _clsk | 1 day | No description |

| _uetvid | 1 year 24 days | No description available. |

| AnalyticsSyncHistory | 1 month | No description |

| apbct_pixel_url | session | No description |

| apbct_visible_fields_0 | session | No description |

| apbct_visible_fields_1 | session | No description |

| apbct_visible_fields_10 | session | No description |

| apbct_visible_fields_2 | session | No description |

| apbct_visible_fields_3 | session | No description |

| apbct_visible_fields_4 | session | No description |

| apbct_visible_fields_5 | session | No description |

| apbct_visible_fields_6 | session | No description |

| apbct_visible_fields_7 | session | No description |

| apbct_visible_fields_8 | session | No description |

| apbct_visible_fields_9 | session | No description |

| ct_checked_emails | session | No description |

| ct_has_scrolled | session | No description |

| ct_mouse_moved | session | No description |

| ct_screen_info | session | No description |

| ictf_master | never | No description available. |

| li_gc | 2 years | No description |

| m | 2 years | No description available. |

| SM | session | No description available. |

| testinfinitycookie | session | No description |

| woocommerce_show_tax | 7 days | No description available. |

| wp_woocommerce_session_c5ac76b408021294cb56bcc27eddf8a1 | 2 days | No description |

2 thoughts on “What Makes Lime Render Eco-Friendly?”

Is it better than silicone and monocouche?

Hi Charlie, it sort of depends on what you want from your façade. Silicone is definitely the most weatherproof, so if you’re living in England, it’s ideal. But lime render is exceptional for heritage projects and it’s highly breathable.