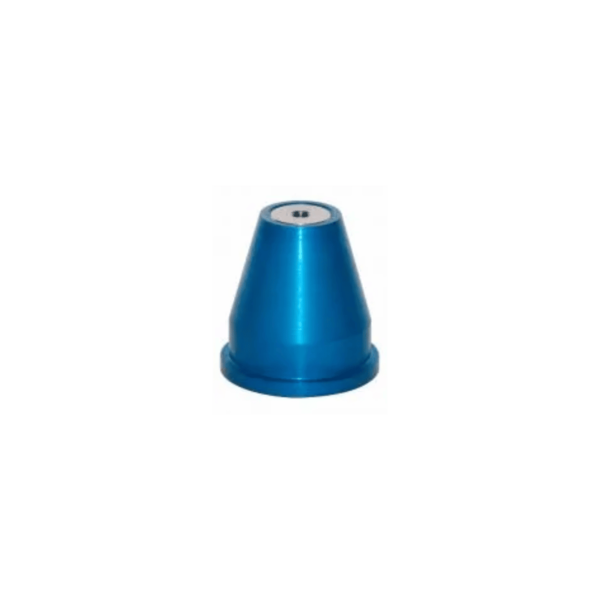

Euromair - Fine Spray Gun Thin Render Coat Nozzles - 4mm - Blue

Brand: Euromair

£62.17

Incl. VAT

£62.17

Incl. VAT (regular price)

Please note: This product has a slightly longer lead time. Our team wiil notify you with an estimated delivery date.