Close filters

Stop Beads

Log in to save items on your shopping lists and access them on all your devices. Guest lists are deleted after 90 days.

Anthracite Stop Bead - No Mesh (2.5m)

SELECT OPTIONS

Brand: Likov

FROM

£3.22

Incl. VAT

FROM

£2.68

Excl. VAT

Ivory Stop Bead - No Mesh (2.5m)

SELECT OPTIONS

Brand: Likov

FROM

£3.10

Incl. VAT

FROM

£2.58

Excl. VAT

Light Grey Stop Bead - No Mesh (2.5m)

SELECT OPTIONS

Brand: Likov

FROM

£3.22

Incl. VAT

FROM

£2.68

Excl. VAT

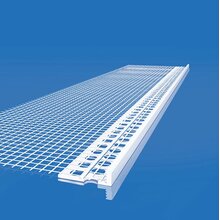

uPVC Stop Bead with Mesh (2.5m)

SELECT OPTIONS

Brand: Likov

FROM

£4.08

Incl. VAT

FROM

£3.40

Excl. VAT

White Stop Bead - No Mesh (2.5m)

SELECT OPTIONS

Brand: Likov

FROM

£3.13

Incl. VAT

FROM

£2.61

Excl. VAT

At EWI Store we supply high-quality beading that is designed to provide stability and strength to EWI and Render-Only systems by preventing cracks.

Stop Beads ensures durability by reinforcing weak points within the structure, while also creating straight lines for a professional finish.

We provide a variety of stop beads for different thicknesses of basecoat and you can find stop beads that come with or without mesh.