- What is Mineral Wool?

- 1. Priming the Substrate for Mineral Wool

- 2. Installing the Starter Track

- 3. Preparing Adhesive for Mineral Wool

- 4. Applying Mineral Wool Insulation Boards

- 5. Installing the Fixings for Mineral Wool

- 6. Applying Beading

- 7. Applying Basecoat and Embedding Mesh

- 8. Priming the Basecoat

- 9. Applying Render

- Download our Complete Guides

- Download as PDF

What is Mineral Wool?

Mineral Wool is a great material for use in external wall insulation. It is similar in composition to fibreglass. However, whilst fibreglass is made up of many glass fibres, mineral wool is a compound of molten volcanic rocks.

Mineral Wool offers more than just insulative qualities. It has an A1 fireproof rating; meaning that it is the most fire resistant insulation material on the market. It also offers great acoustic insulation to help reduce and control noise pollution. Mineral Wool is also a breathable insulation material.

We have created a handy buyers guide to equip you with the knowledge needed to understand the mineral insulation installation process.

1. Priming the Substrate for Mineral Wool

Much like our other EWI systems, applying primer is a necessary first step when installing a Mineral Wool system. This ensures your Mineral Wool insulation system will last.

If installing onto brickwork, use EWI-301 Water Based Primer. Apply this to the substrate using a roller or brush.

If rendering onto a smooth substrate, use the EWI-310 Universal Primer. The formula contains aggregates that create a rough surface for adhesion.

2. Installing the Starter Track

Starter Tracks create a solid base for Mineral Wool boards to be installed onto. Holes are drilled and the starter tracks are screwed into place just above the DPC. Starter Tracks can accommodate different thicknesses of insulation.

When installing a Starter Track for a Mineral Wool insulation system, you have the following 2 options:

1) uPVC Starter Track: Ensures the thermal bridging is kept to a minimum. Coverage = 2m.

2) Aluminium Starter Track: More cost-effective option. Comes with a clip-on stop bead.

Coverage = 2.5m.

3. Preparing Adhesive for Mineral Wool

At EWI Store, all our systems are held in place using a combination of high-quality adhesives and mechanical fixings.

The nature of Mineral Wool Insulation means it requires a very strong adhesive. In this instance, we highly suggest the use of the EWI-225 Premium Basecoat. EWI-225 is our most versatile adhesive that can be used as an adhesive and a basecoat.

Simply use a paddle mix to mix the dry mix bag with 5.9L of water. Each bag of EWI-225 has coverage of 4m2 when used as an adhesive, and a drying time of 24-48 hours.

4. Applying Mineral Wool Insulation Boards

The nature of Mineral Wool insulation boards means that they are non-combustible and vapour permeable. Therefore, they are perfect for use with breathable, thin-coat renders. We suggest using EWI Pro’s Silicone Render alongside this product.

We are incredibly proud that our Rockwool External Wall Dual Density Slabs carry an A1 rating for non-combustibility. This is the highest possible rating that can be awarded to an insulation material.

Our mineral wool comes in a range of thicknesses. However, building regulations suggest a 100mm thickness is ideal for mineral wool insulations.

When applying adhesive to Mineral Wool boards, apply around the perimeter and place 3 dabs in the centre. This way, we can ensure any imperfections on the surface are evened out.

5. Installing the Fixings for Mineral Wool

Rockwool mineral insulation requires one fixing to be fit per corner and one in the centre of the board. We highly suggest using metal fixings with mineral wool insulation systems, to better support binding to the wall.

Our metal fixings come in a range of lengths. This ensures all thicknesses of insulation are catered to.

It should be noted that fixings should be at least 40mm longer than the thickness of the insulation. This ensures the Rockwool is held securely in place.

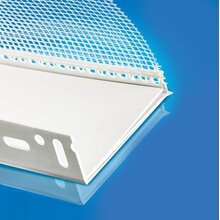

6. Applying Beading

A key component of the Mineral Wool installation process is beading. This works to reinforce certain external wall areas that are more prone to damage than others.

The beads that will be required will depend on the areas that need reinforcement. For example, corners, doors and windows.

At EWI Store, our selection of render beads allows you to choose the perfect beading for your property. Our beads are uPVC and designed to be embedded in the basecoat layer.

7. Applying Basecoat and Embedding Mesh

When creating a reinforced basecoat layer with Mineral Wool, we highly recommend the use of EWI Pro’s EWI-225 Premium Basecoat. When applied at a thickness of 6mm, the fibreglass mesh can be successfully embedded in the layer. This layer reinforces the system with a strong, flexible and waterproof base.

Once dry, the reinforcement basecoat layer provides a strong, flexible and waterproof layer.

• Coverage rates (basecoat): 1 x 25kg bag covers 3.5m2

• Coverage rates (mesh): 1 x 50m2 roll covers 42.5m2 when overlapped. Our standard mesh is sold in rolls of 50m2

8. Priming the Basecoat

Following application of the mesh, and before rendering, your next port of call should be to prime the basecoat. Priming the basecoat aids adhesion between the basecoat and render and also helps limit absorption to the basecoat, allowing the render to cure correctly. Our EWI-333 Topcoat Primer is designed specifically for this purpose and can be tinted to match the colour of your silicone render.

EWI-333 has a drying time of 12-24 hours, depending on the coverage. Its coverage rates are listed below:

- 7kg = 20m 2

- 20kg = 60m 2

9. Applying Render

The final step in the Mineral Wool installation process is to apply render once the topcoat primer has fully dried.

Since most of our renders are thin coat renders, the thickness of the topcoat depends on the grain size of the render. For example, the available grain sizes for EWI-075 Silicone Render are 1mm, 1.5mm, 2mm and 3mm. If you were to purchase the 2mm Silicone Render, your topcoat should be applied no thicker than 2mm.

Render should be applied using a trowel and any excess render should always be removed. Then, use a plastic float to apply the render in a circular motion to achieve your desired finish.

Below are the coverage rates you can expect from each grain size:

- 1.0mm = 12m2 - 13m2

- 1.5mm = 9m2 - 10m2

- 2.0mm = 7m2 - 8m2

- 3.0mm = 5m2 - 6m2

Download our Complete Guides

If you are looking to buy mineral wool, or any products mentioned, they are available in the EWI Store.

If you have any further questions, please contact our Sales team on: 0203 034 0022.

You can also download a copy of our complete buyers guide.

Download as PDF

Download this guide as a PDF to view offline.

Download