4.8 out of 5 Stars on TrustPilot

Guide to Solid Wall Insulation

Solid wall insulation is a critical component in the energy efficiency framework of older buildings, which often feature solid walls as a fundamental aspect of their construction. Unlike newer buildings that typically employ cavity walls, which consist of two layers with a space in between, solid walls are composed of a single solid layer that does not naturally offer an insulative barrier. This characteristic makes solid walls significantly less efficient at retaining heat, leading to higher energy consumption and heating costs.

Origin of solid walls and development of cavity walls

Solid walls have been a fundamental construction method for thousands of years. Traditionally, these walls were built using locally available materials such as stone or brick, laid in thick, sturdy layers to provide structural integrity and some level of thermal mass. In historical contexts, the thickness of these walls served not only as a means of support but also to retain heat in cooler weather. However, solid walls are inherently inefficient at maintaining indoor temperatures without additional insulation, as they allow heat to pass through easily. Most properties built before 1920 in the UK will have solid walls instead of cavity walls. The move towards cavity walls was prompted around the 1920s and 1930s due to the problems with damp. Once damp seeps into the exterior of a solid wall, it’ll migrate through the wall and affect the structural integrity and indoor air quality.

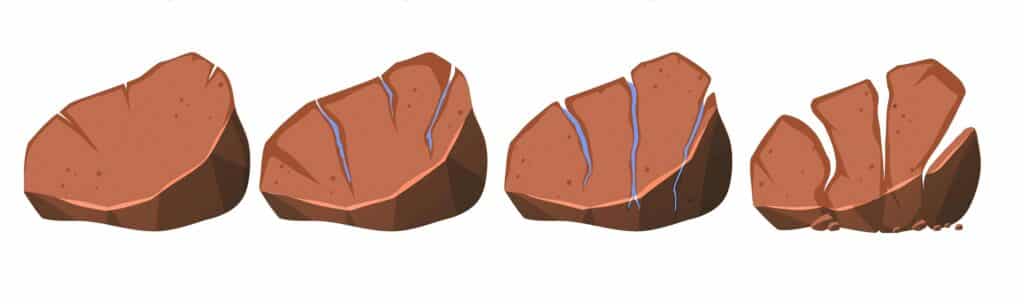

With the adoption of brick and stone in construction, various methods were attempted to combat dampness, including applying render on pre-1920 buildings to protect the underlying brick. This approach was partially successful but failed in extreme wet conditions as dampness would seep through the saturated walls. To counteract this, walls were constructed thickly, though this was not always effective. The Victorian era introduced a slate damp-proof course, preventing moisture from rising from the ground. However, this solution was prone to failure due to the brittle nature of the slate and the possibility of it cracking if the building moved.

Cavity walls began to be widely adopted in the early 20th century, particularly in regions like the UK and other parts of Europe, where damp and variable weather conditions could severely affect buildings. A cavity wall design includes two ‘skins’ separated by a hollow space (cavity). The cavity is a barrier to reduce moisture penetration into the building’s interior and was initially not intended for thermal benefits. It wasn’t until the energy crises of the 1970s that the cavity began to be seen as a valuable zone for inserting insulation material.

Further advancements

The mid-20th century marked a significant shift with new insulation materials such as fibreglass, foam, and, later, more advanced aerogels and vacuum insulation panels. These materials could be placed within the cavity of walls or added to solid walls internally or externally, greatly enhancing a building’s energy efficiency. This period also saw the rise of energy awareness and the development of building regulations that emphasised thermal efficiency’s importance in reducing energy consumption and minimising environmental impact.

Today, the choice between using solid or cavity walls often depends on climatic conditions, aesthetic considerations, historical preservation, and energy standards. In some cases, older buildings with solid walls are retrofitted with insulation to improve energy efficiency without compromising their structural integrity or historical value. New building technologies have also enabled the construction of thinner, more energy-efficient solid walls that incorporate insulation materials within their structure.

Solid wall insulation

Solid walls are commonly constructed from brick, stone, concrete, or timber, each chosen for their robust structural qualities. However, one of the drawbacks of these materials is their inherently poor thermal resistance. Unlike cavity walls, solid walls lack this space, which features a gap between two layers that can be filled with insulating material. This absence means that any insulation must be applied directly to the surfaces of the walls, either on the inside or the outside.

Two primary approaches address this issue: External Wall Insulation (EWI) and Internal Wall Insulation (IWI). External wall insulation involves adding a protective layer to the outside of the building. This method improves thermal performance, revamps the exterior appearance, and protects the underlying structure from weather-related damage. Conversely, internal wall insulation is applied to the inside surfaces of the walls. While this technique is often less disruptive to the building’s external appearance and can be implemented regardless of external space limitations, it does reduce the internal floor area. It requires careful installation to avoid issues with moisture and ventilation.

Solid wall insulation – externally

External Wall Insulation (EWI) is a system used to enhance the thermal performance of buildings with solid walls, which are typically less efficient at insulating against heat loss than cavity walls. EWI involves attaching a layer of insulation material to the exterior walls of a building, which is then covered with a protective render or cladding. This improves energy efficiency and refreshes the building’s exterior appearance.

Expanded Polystyrene (EPS)

EPS is one of the most widely used materials for external wall insulation due to its cost-effectiveness and excellent insulating properties. It is lightweight and easy to cut and shape, making it versatile for various building contours and shapes. EPS boards are typically available in different densities, offering varying thermal resistance and strength levels. However, EPS is combustible at higher temperatures, so it must be adequately covered and treated to meet fire safety regulations.

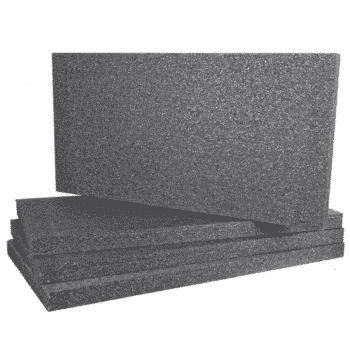

Mineral Wool

Mineral wool insulation is made from rock or slag and is known for its fire-resistant properties, making it a safer option for fire safety. Rockwool has a fire rating of A1, which is top of the class. It offers good thermal performance and excellent sound insulation, which can be particularly beneficial in urban environments or buildings near busy roads. Mineral wool is denser than EPS, providing better thermal mass and a more stable indoor temperature throughout the day.

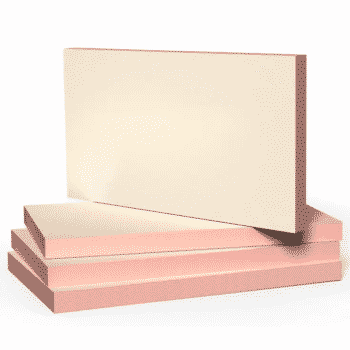

Kingspan K5

Kingspan K5 boards are made from phenolic foam, which offers one of the highest levels of thermal efficiency among insulation materials. Phenolic foam has a closed-cell structure that provides excellent moisture resistance and thermal performance. Kingspan K5 boards are also thinner than other types of insulation for the same level of thermal resistance, making them an effective solution where maintaining the building’s profile is essential. However, they tend to be more expensive than EPS or mineral wool and must be carefully installed to avoid issues with moisture ingress.

-

Rockwool External Wall Dual Density Slab

Rated 5.00 out of 5From £25.19 Incl. VATFrom £20.99 Excl. VAT -

EPS Insulation (1 board = 0.72m²)

Rated 5.00 out of 5From £2.60 Incl. VATFrom £2.17 Excl. VAT -

K5 Kingspan External Wall insulation Board (0.72m²)

Rated 4.67 out of 5From £11.39 Incl. VATFrom £9.49 Excl. VAT

Wood Fibre

Wood fibre insulation is an eco-friendly option made from natural wood fibres. It is breathable, which helps manage moisture within the building structure, making it particularly suitable for older buildings where condensation might be a concern. Wood fibre boards also have good thermal mass, helping to reduce overheating in summer and keeping warmth in winter. This type of insulation is often chosen for buildings where environmental sustainability is a priority or for use in conservation areas where maintaining the aesthetic with natural materials is essential.

Benefits of external wall insulation

- Reduced heat loss and energy bills

- Fewer draughts and increased sense of comfort

- No disruption to the house while being installed

- Does not reduce internal floor area

- Walls to contribute to thermal mass

- Improves weatherproofing and sound resistance

- Increases the life of the wall

- Reduces condensation on internal walls

Drawbacks of external wall insulation

Most drawbacks associated with external wall insulation revolve around incorrect installation. For example, any gaps or cracks, irrespective of size, will invite water penetration; once damp becomes trapped within insulated walls, it will continue inwards. Potential rot and mould can affect the home’s structural integrity and indoor air quality.

Solid wall insulation – EWI and the damp problem

Historically, walls were designed either to be impermeable to prevent moisture penetration from both sides or to be breathable, allowing some moisture ingress but enabling it to evaporate away. The advent of the cavity wall introduced a design where the cavity acts as a barrier to moisture. The cavity prevents direct moisture penetration through the outer wall, with any moisture that does enter being evaporated away by air movement within the cavity itself. This design effectively manages moisture by keeping the inner wall surface dry.

However, many modern external wall insulation (EWI) materials are non-permeable and are finished with render or cladding to prevent rainwater penetration. While these materials effectively keep out rain, they do not address internal moisture produced from daily activities like cooking, washing, and breathing. This internal moisture can accumulate, necessitating increased ventilation within the home to prevent it from condensing on wall surfaces.

Detailing is crucial in preventing damp problems when installing EWI. Regulations about verge trims are patchy and insufficient; however, they should be used. The primary guidance for roofs is to extend the soffits. Water penetration is a huge issue, so taking steps to prevent it is essential.

Managing details at critical junctions, such as around windows and doors and the damp-proof course level, is vital to prevent thermal and moisture bridging. Extending the rafters may be necessary at the roof level to accommodate the added thickness of insulated walls.

Moreover, installing insulation changes the location of the dew point—the temperature at which air condenses into water. External insulation warms the internal wall, pushing the dew point outward toward the colder external air, which reduces the risk of condensation inside. However, if the dew point falls within these areas, condensation might occur between the insulation and the wall or within the insulation itself. To counter this, most EWI systems include a vapour barrier between the wall and the insulation to manage condensation risks.

Costs of solid wall insulation

Solid wall insulation is not the cheapest option; however, it is the most effective. Below, we’ve drawn up rough costs for different property types, but these can vary depending on the type of insulation and render chosen.

| Type of home | Size (sqm) | Bedrooms | Cost | Savings | Payback |

| Detached | 147 | 4 | £15,000 – £20,000 | £1,000 | 20 years |

| Semi-detached | 96 | 3 | £8,000 – £10,000 | £700 | 15 years |

| Mid-terraced | 64-100 | 2-3 | £6,000 – £8,000 | £500 – £700 | 12-15 years |

| Bungalow | 77 | 1-2 | £6,000 – £8,000 | £700 | 12-15 years |

How do we install solid wall insulation?

Our primary focus is on external wall insulation when it comes to solid wall insulation. However, some materials, especially the insulation boards, can be used in both. For example, when you build a stud wall and insulate the stud cavity, you can use mineral wool or sheep’s wool.

The process of installing solid wall insulation starts with assessing the substrate. Depending on the state of the wall, you may need to consider certain things and take certain steps.

- Wall Preparation: Begin by assessing the condition of the external walls. Depending on their state, you might simply need a thorough scrub or, in some cases, a complete removal of the existing external coating. If walls are smooth, apply EWI-310 Universal Primer to enhance adhesive bonding. For uneven surfaces, use EWI-260 Levelling Mortar to create a smooth base. Additionally, treat any organic growth with a fungicidal wash.

- Starter Tracks Application: Install the starter tracks above the damp-proof course once the walls are prepped. These tracks facilitate the installation of insulation panels and protect the bottom edge of the insulation from weather and moisture damage. Aluminium starter tracks are recommended for their durability and neat finish.

- Insulation Application: Attach the insulation boards using the modified dot-and-dab method—three dots in the centre and a continuous layer around the perimeter. EWI-220 EPS Basecoat can serve as the adhesive. Apply the basecoat with a notched trowel to ensure uniform thickness, and use mechanical fixings (6 per square meter) to secure the insulation to the wall. Allow the basecoat to set for 2-3 days before proceeding.

- Beading and Verge Trims Application: Apply different beads before the final basecoat to reinforce the insulation system at vulnerable points. Corner beads protect external corners, movement beads seal vertical joints, and bellcast beads deflect water from the wall base.

- Basecoat and Mesh Layer Application: Another basecoat layer is applied after the initial setting period. With a flat-edged trowel, embed fibreglass mesh into this layer, ensuring 10-15 cm overlaps between strips to increase tensile strength and prevent cracking.

- Render Primer Application: Though optional, applying a render primer can enhance the adhesion and durability of the final render coat. Select a primer suited to the type of render being used.

- Render Application: Apply the chosen render (e.g., Silicone Render) at the specified thickness to provide a durable, flexible, and breathable external layer to the EWI system. The render should be no thicker than prescribed to maintain the system’s efficiency and aesthetic appeal.

Insulating old stone walls

The choice of insulation material is critical for properties with breathable masonry, such as those built with certain types of stone or older brick that require ventilation to manage moisture. One effective solution is to use natural, breathable materials like wood-fibre insulation. This can be coated with a moisture-permeable lime render and finished with breathable paint. This approach maintains the wall’s ability to “breathe” by allowing moisture to evaporate.

The quality and condition of the masonry also play significant roles in deciding the appropriate insulation strategy. For example, spalling—where the brick’s surface flakes off—often indicates freeze-thaw cycles. This occurs when moisture penetrates the brick, freezes, and causes flaking. This not only affects the brick’s appearance but also its structural integrity.

Contrary to stone, a typical brick wall is not inherently breathable. In such cases, rigid foam insulations are appropriate as they don’t rely on the wall’s ability to expel moisture. These insulations can be mechanically fixed to the wall and then covered with various finishes such as render, timber, or other claddings. This method ensures that the external insulation has little impact on the structural performance of the wall but significantly enhances its thermal performance.

Solid wall insulation – internal

Internal Wall Insulation improves the thermal efficiency of buildings with solid walls, particularly when external modifications are impractical or undesirable. This approach involves applying insulation materials directly to the inner surfaces of external walls and can be implemented using several different methods.

One common method is rigid insulation boards made from polystyrene, polyurethane, or phenolic foam. These boards are attached directly to the walls using adhesive or mechanical fixings and provide a high level of insulation with a relatively slim profile. Another approach is stud wall insulation, which involves constructing a metal or wooden frame fixed to the wall. The gaps between the studs are filled with insulating material such as mineral wool or fibreglass. This method is particularly versatile as it allows for easy integration of services like electrical wiring and plumbing within the stud cavity. Flexible thermal linings, though less common, are another option where minimal changes to the wall structure are preferred.

Internal wall insulation has several advantages. It is generally less expensive than external wall insulation since it does not require extensive scaffolding or external modifications. It also allows for control over the interior finish, offering the opportunity to simultaneously upgrade a room’s aesthetics.

However, there are significant challenges to consider. Installing IWI reduces the available interior space due to the thickness of the insulation and any framing used. This can be particularly problematic in smaller rooms. Thermal bridging at floors, ceilings, and around windows can also diminish the insulation’s effectiveness and needs careful attention during installation. Moisture management is another critical concern; improper installation can lead to condensation issues within the wall, potentially causing damp and mould. Furthermore, the installation process can be quite disruptive, often necessitating the temporary removal of room features like skirting boards, electrical outlets, and radiators.

Is EWI better than IWI for solid wall insulation?

This is a complicated answer, but we believe that it is! There are a few reasons for this:

- Bigger savings – The Energy Savings Trust states that EWI can save you up to £700 annually on your energy bills, whereas IWI saves less.

- No loss of internal floor space – Because the walls are insulated externally, you don’t lose valuable floor space within your home.

- Less disruptive – IWI installation involves working from room to room, disrupting the day-to-day. Installing EWI does none of that, as no work is done internally.

- Improved aesthetics – EWI allows you to improve the external facade with attractive render finishes. We can tint our render to any shade or colour, so the choice of customisation is almost endless.

- Weatherproofing and acoustic insulation – Combining mineral wool and our silicone renders results in reduced noise from outside and a more weather-resistant facade. Silicone render is hydrophobic and resistant to corrosion.

Can you also insulate cavity walls?

Yes, you can! Typically, the cavity in these walls is ventilated to allow moisture within the cavity to evaporate and to prevent damp issues in the interior. This ventilation, while crucial for moisture management, can inadvertently reduce the effectiveness of EWI. The heat from the house’s interior can escape into the ventilated cavity and then be lost to the outside atmosphere before reaching the external insulation. This can render the EWI less effective, as much of the heat it is supposed to retain has already been dissipated.

Moreover, problems can arise if the cavity-fill insulation within the walls fails. Failure often occurs when the insulation material allows rainwater to penetrate across the cavity, leading to damp problems inside the building. However, adding EWI with a weatherproof render can address this issue by preventing rainwater from entering the walls in the first place. This resolves the water ingress issue and ensures that the cavity-fill insulation functions effectively as a thermal barrier.

A practical approach to optimising cavity wall insulation is combining cavity fill with EWI. Doing so allows you to split the necessary insulation thickness between the internal cavity and the external surface, thus enhancing overall insulation without relying solely on one method. For instance, if the typical cavity width is about 50mm, adding 20mm of external insulation can significantly improve the wall’s U-value, making it more thermally efficient.

Facebook

Twitter

LinkedIn

Your cart

Trade Account Login

We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. By clicking “Accept All”, you consent to the use of ALL the cookies. However, you may visit "Cookie Settings" to provide personalised consent.

Manage consent

Privacy Overview

This website uses cookies to improve your experience while you navigate through the website. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. We also use third-party cookies that help us analyze and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may affect your browsing experience.

Necessary cookies are absolutely essential for the website to function properly. These cookies ensure basic functionalities and security features of the website, anonymously.

| Cookie | Duration | Description |

|---|---|---|

| __stripe_mid | 1 year | This cookie is set by Stripe payment gateway. This cookie is used to enable payment on the website without storing any patment information on a server. |

| __stripe_sid | 30 minutes | This cookie is set by Stripe payment gateway. This cookie is used to enable payment on the website without storing any patment information on a server. |

| _GRECAPTCHA | 5 months 27 days | This cookie is set by the Google recaptcha service to identify bots to protect the website against malicious spam attacks. |

| apbct_cookies_test | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_page_hits | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_prev_referer | session | Functional cookie placed by CleanTalk Spam Protect to store referring IDs and prevent unauthorized spam from being sent from the website. |

| apbct_site_landing_ts | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_site_referer | 3 days | This cookie is placed by CleanTalk Spam Protect to prevent spam and to store the referrer page address which led the user to the website. |

| apbct_timestamp | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_urls | 3 days | This cookie is placed by CleanTalk Spam Protect to prevent spam and to store the addresses (urls) visited on the website. |

| AWSALBCORS | 7 days | This cookie is managed by Amazon Web Services and is used for load balancing. |

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| ct_checkjs | session | CleanTalk–Used to prevent spam on our comments and forms and acts as a complete anti-spam solution and firewall for this site. |

| ct_fkp_timestamp | session | CleanTalk sets this cookie to prevent spam on the site's comments/forms, and to act as a complete anti-spam solution and firewall for the site. |

| ct_pointer_data | session | CleanTalk sets this cookie to prevent spam on the site's comments/forms, and to act as a complete anti-spam solution and firewall for the site. |

| ct_ps_timestamp | session | CleanTalk sets this cookie to prevent spam on the site's comments/forms, and to act as a complete anti-spam solution and firewall for the site. |

| ct_sfw_pass_key | 1 month | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| ct_timezone | session | CleanTalk–Used to prevent spam on our comments and forms and acts as a complete anti-spam solution and firewall for this site. |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features.

| Cookie | Duration | Description |

|---|---|---|

| __zlcmid | 1 year | This cookie is used by Zendesk live chat and is used to store the live chat ID. |

| bcookie | 2 years | LinkedIn sets this cookie from LinkedIn share buttons and ad tags to recognize browser ID. |

| bscookie | 2 years | LinkedIn sets this cookie to store performed actions on the website. |

| lang | session | LinkedIn sets this cookie to remember a user's language setting. |

| lidc | 1 day | LinkedIn sets the lidc cookie to facilitate data center selection. |

| UserMatchHistory | 1 month | LinkedIn sets this cookie for LinkedIn Ads ID syncing. |

Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.

| Cookie | Duration | Description |

|---|---|---|

| __utma | 2 years | This cookie is set by Google Analytics and is used to distinguish users and sessions. The cookie is created when the JavaScript library executes and there are no existing __utma cookies. The cookie is updated every time data is sent to Google Analytics. |

| __utmb | 30 minutes | Google Analytics sets this cookie, to determine new sessions/visits. __utmb cookie is created when the JavaScript library executes and there are no existing __utma cookies. It is updated every time data is sent to Google Analytics. |

| __utmc | session | The cookie is set by Google Analytics and is deleted when the user closes the browser. It is used to enable interoperability with urchin.js, which is an older version of Google Analytics and is used in conjunction with the __utmb cookie to determine new sessions/visits. |

| __utmt | 10 minutes | Google Analytics sets this cookie to inhibit request rate. |

| __utmv | 2 years | The __utmv cookie is set on the user's device, to enable Google Analytics to classify the visitor. |

| __utmz | 6 months | Google Analytics sets this cookie to store the traffic source or campaign by which the visitor reached the site. |

| sib_cuid | 6 months | Purechat uses this cookie to send data to purechat.com, to connect visitors to the reservation team and track visitors to stay on portal. |

| SRM_B | 1 year 24 days | Used by Microsoft Advertising as a unique ID for visitors. |

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc.

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _gat_gtag_UA_61069204_2 | 1 minute | Set by Google to distinguish users. |

| _gat_UA-61069204-2 | 1 minute | A variation of the _gat cookie set by Google Analytics and Google Tag Manager to allow website owners to track visitor behaviour and measure site performance. The pattern element in the name contains the unique identity number of the account or website it relates to. |

| _gcl_au | 3 months | Provided by Google Tag Manager to experiment advertisement efficiency of websites using their services. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| _uetsid | 1 day | This cookies are used to collect analytical information about how visitors use the website. This information is used to compile report and improve site. |

| CONSENT | 2 years | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. These cookies track visitors across websites and collect information to provide customized ads.

| Cookie | Duration | Description |

|---|---|---|

| _fbp | 3 months | This cookie is set by Facebook to display advertisements when either on Facebook or on a digital platform powered by Facebook advertising, after visiting the website. |

| ANONCHK | 10 minutes | The ANONCHK cookie, set by Bing, is used to store a user's session ID and also verify the clicks from ads on the Bing search engine. The cookie helps in reporting and personalization as well. |

| fr | 3 months | Facebook sets this cookie to show relevant advertisements to users by tracking user behaviour across the web, on sites that have Facebook pixel or Facebook social plugin. |

| MUID | 1 year 24 days | Bing sets this cookie to recognize unique web browsers visiting Microsoft sites. This cookie is used for advertising, site analytics, and other operations. |

| NID | 6 months | NID cookie, set by Google, is used for advertising purposes; to limit the number of times the user sees an ad, to mute unwanted ads, and to measure the effectiveness of ads. |

| test_cookie | 15 minutes | The test_cookie is set by doubleclick.net and is used to determine if the user's browser supports cookies. |

| uuid | 6 months | MediaMath sets this cookie to avoid the same ads from being shown repeatedly and for relevant advertising. |

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt-remote-device-id | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt.innertube::nextId | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |

| yt.innertube::requests | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |

Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet.

| Cookie | Duration | Description |

|---|---|---|

| _clck | 1 year | No description |

| _clsk | 1 day | No description |

| _uetvid | 1 year 24 days | No description available. |

| AnalyticsSyncHistory | 1 month | No description |

| apbct_pixel_url | session | No description |

| apbct_visible_fields_0 | session | No description |

| apbct_visible_fields_1 | session | No description |

| apbct_visible_fields_10 | session | No description |

| apbct_visible_fields_2 | session | No description |

| apbct_visible_fields_3 | session | No description |

| apbct_visible_fields_4 | session | No description |

| apbct_visible_fields_5 | session | No description |

| apbct_visible_fields_6 | session | No description |

| apbct_visible_fields_7 | session | No description |

| apbct_visible_fields_8 | session | No description |

| apbct_visible_fields_9 | session | No description |

| ct_checked_emails | session | No description |

| ct_has_scrolled | session | No description |

| ct_mouse_moved | session | No description |

| ct_screen_info | session | No description |

| ictf_master | never | No description available. |

| li_gc | 2 years | No description |

| m | 2 years | No description available. |

| SM | session | No description available. |

| testinfinitycookie | session | No description |

| woocommerce_show_tax | 7 days | No description available. |

| wp_woocommerce_session_c5ac76b408021294cb56bcc27eddf8a1 | 2 days | No description |