- Building Regulation Approval

- Thermal Performance

- Fire Safety

- Ventilation

- Materials and Workmanship

- Protection from Falling

- Key Safety Measures for Workers:

- Post-Installation Considerations:

- Conservation Areas and Listed Buildings

- Striking the Balance with EWI:

- Drainage and Water Absorption

- Key Considerations for Drainage and Water Absorption:

- Sound Insulation

- Key Considerations for Sound Insulation in EWI:

- Appearance

- Access and Facilities for the Disabled

In the rapidly evolving world of UK construction and home renovation, External Wall Insulation (EWI) has emerged as a cornerstone for enhancing energy efficiency. It's not just about layering an insulating material on a home's external walls. It is about transforming the way homes interact with the environment, dramatically reducing energy consumption, and making our living spaces more comfortable. But like all facets of construction, the installation of EWI is not without its own set of rules. The EWI Building Regulations in the UK, known for their comprehensive and detail-oriented nature, encompass a range of specifications. These ensure safety, durability, and overall effectiveness. As we delve deeper into this topic, this blog aims to unravel the intricacies of these regulations, offering homeowners, builders and architects a clear roadmap for compliant installations. Whether you're considering the transformational potential of EWI for a historic building, a modern home, or a high-rise apartment complex, understanding the regulatory framework is crucial. From fire safety concerns stemming from tragic events like the Grenfell Tower disaster to the aesthetics in conservation zones, we'll navigate standards, permissions, and best practices that surround EWI in the UK.

Building Regulation Approval

Building Regulation Approval is not the same as planning permission. While planning permission pertains to the right to perform a particular development or change to a property, Building Regulation Approval ensures that any such change or development adheres to set construction and design standards. These standards are in place to safeguard the health and safety of the people in and around the buildings. Whether it's a new build, an extension, or significant modifications like EWI, these changes can impact the structural integrity, fire safety, and overall energy performance of a building. Hence, they must be rigorously evaluated. The process usually begins with submitting detailed plans of the proposed work to the local authority's building control department. These plans should encompass all aspects of the installation, including materials, design, and any potential impact on existing structures. The local authority will then assess these plans against the current Building Regulations. Post-approval, there are typically two stages of inspection: an initial examination before or during the early stages of work, and a final inspection upon completion. This ensures that the work, as executed, aligns with the plans initially approved and meets all required standards. Upon the successful inspection of the completed work, the local authority will issue a completion certificate. This document is crucial. Not only does it verify that the work meets regulatory standards, but it's also a vital piece of documentation should you ever decide to sell your property.

Thermal Performance

Thermal performance refers to a building's ability to retain heat during colder periods and repel excess heat during warmer months. This balance is pivotal in ensuring comfortable living spaces, reducing energy consumption, and minimising environmental impact. The UK's Building Regulations Part L specifically deals with the conservation of fuel and power in buildings. Under this regulation, there are strict guidelines on the minimum U-values that renovated walls or new constructions must achieve. EWI installations should be compliant with these values, ensuring that the insulating material and its thickness are up to the mark in delivering the required thermal performance. While EWI plays a vital role, it's essential to consider a building's overall thermal efficiency. This includes examining windows, doors, roofs, and floors. For comprehensive thermal performance, every aspect of the building envelope should be evaluated and optimised.

Fire Safety

While the primary purpose of EWI is to enhance a building's thermal performance, its composition and installation can impact fire resistance. The materials used, their arrangement, and the overall system design influence the material's reaction to fire. The UK's Building Regulations Part B specifically deals with fire safety, outlining requirements to ensure that buildings provide adequate resistance to the spread of fire and offer suitable means of escape for occupants. Within the context of EWI, these regulations focus on materials, their fire resistance properties, and their arrangement on the building's façade. When selecting materials for EWI, opt for those that are classified as having low combustibility or are non-combustible. After the devastating Grenfell Tower fire in 2017, the emphasis on using fire-resistant cladding and insulation materials has become even more pressing. This is especially pertinent for tall buildings. [gallery columns="2" link="file" size="full" ids="68008,68009"] For buildings above 18 meters in height, there are specific regulations in the UK about the types of materials that can be used for EWI. The regulations address the challenges associated with evacuating taller structures. There is potential for fires to spread more rapidly throughout these buildings. Therefore, stringent regulations are crucial. Introducing fire barriers within the EWI system can halt or slow down the spread of fire. These barriers, usually made of fire-resistant materials, are placed at strategic intervals, especially around potential fire-breaching points like windows and ventilation systems. Like all fire safety measures, the EWI system should undergo regular inspections to ensure its integrity is maintained. Over time, wear and tear, or unforeseen damages, can compromise the system's fire resistance, and it's crucial to detect and address these issues promptly.

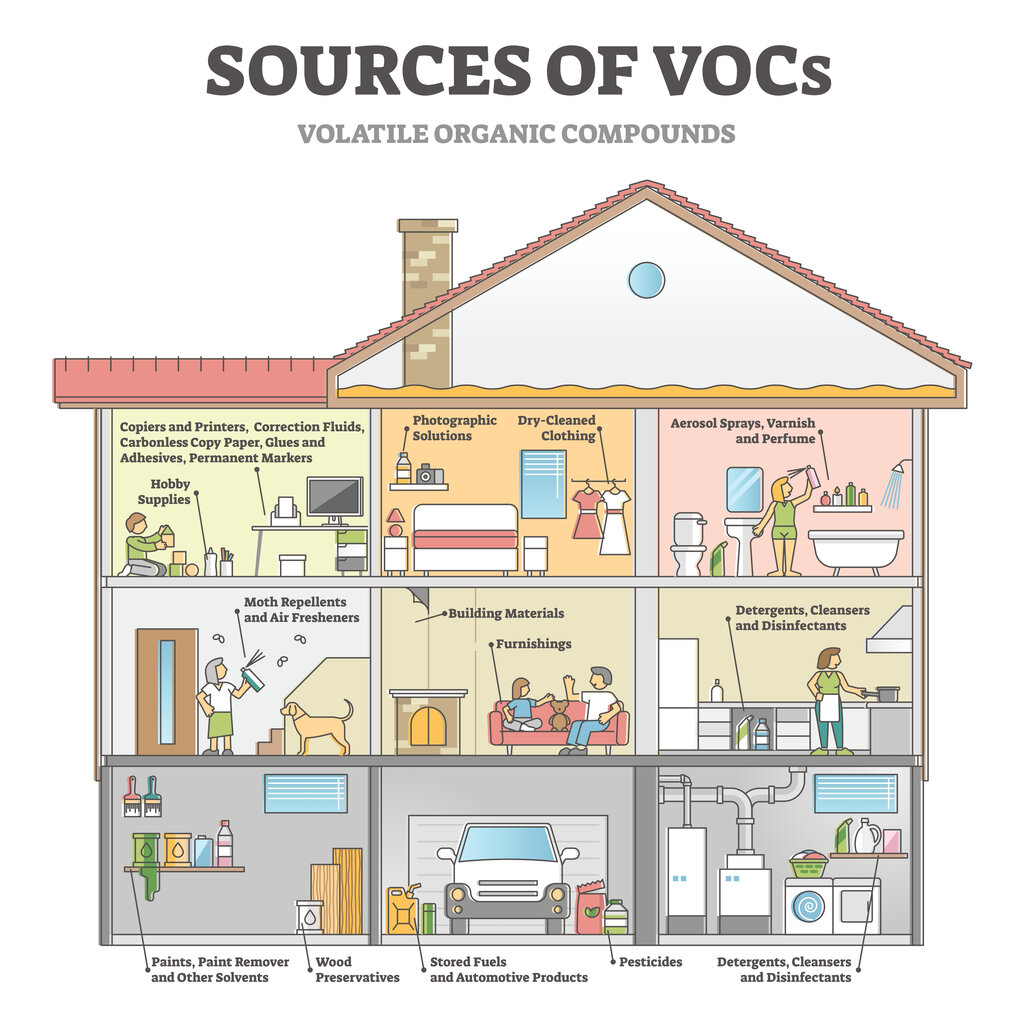

Ventilation

EWI acts as a sealant, wrapping the building to prevent heat loss. While this is excellent for thermal performance, it could inadvertently lead to reduced air exchange if not properly managed. Ventilation ensures there's an adequate flow of fresh air, preventing moisture build-up and ensuring the well-being of occupants.

In the UK, Building Regulations Part F specifically addresses ventilation. It ensures that homes and other buildings have efficient and effective ventilation systems, particularly after significant alterations like the addition of EWI. This regulation is geared towards maintaining good indoor air quality and preventing issues like mould growth due to condensation.

One of the main challenges with improved insulation and airtightness is the potential for condensation build-up. Proper ventilation ensures that moist air is regularly expelled from the building, preventing dampness and mould growth, which can be detrimental to both the structure and its occupants.

Adequate ventilation ensures a continuous supply of fresh air, which can have numerous benefits. This includes reducing allergens and pollutants, and enhancing overall well-being by providing a fresher indoor environment.

While ventilation is crucial, it's essential to ensure it doesn't undermine the energy efficiency brought about by the EWI. Systems like MVHR strike a balance, ensuring fresh air without significant heat loss.

Materials and Workmanship

The effectiveness of EWI depends significantly on the quality of materials used and the craftsmanship with which they are installed. Both factors play a pivotal role in ensuring that the insulation performs optimally, remains durable, and integrates seamlessly with the existing structure. The UK's Building Regulations Part 7 provides guidelines specific to the quality of materials and the standards of workmanship. It emphasises that both materials and workmanship must be appropriate, robust, and fit for their intended purpose to ensure the building's longevity and safety. Before hiring professionals, it's crucial to check for accreditations or certifications. Many organisations provide training and certification to EWI installers, guaranteeing a certain standard of expertise and proficiency. Manufacturers often provide warranties on their materials, which serve as a testament to their quality. Similarly, reputable installation companies offer guarantees on their work, ensuring peace of mind for the building owner.

Protection from Falling

EWI installations often require workers to operate at varying heights, especially for tall residential and commercial buildings. This elevates the risk of falls, which can lead to severe injuries or even fatalities. In the UK, Building Regulations Part K specifically deals with ensuring that buildings are designed and constructed to provide protection against risks of falling, collision, and impact. While it predominantly addresses the internal aspects, the principles can be extrapolated to consider external installations like EWI.

Key Safety Measures for Workers:

- Scaffolding: Properly erected and secure scaffolding provides a safe platform for workers. It should be regularly inspected to ensure its stability and safety.

- Safety Harnesses: For added safety, especially at significant heights, workers should wear safety harnesses that are securely anchored.

- Edge Protection: Temporary barriers or guardrails can be installed at open edges to prevent accidental falls.

- Safety Netting: In areas where there's a risk of falling from a considerable height, safety Netting can be used as an added precaution.

Post-Installation Considerations:

Once the EWI installation is complete, the building's new features or elements could pose a risk of falling. These include:

- Balconies: If EWI work incorporates or modifies balconies, they should have adequate guardrails or barriers.

- Windows: Ground-floor windows or those adjacent to flat roofs or balconies should be designed to prevent accidental falls. This might involve fixed screens, window restrictors, or other safety measures.

Future maintenance or modification of the EWI will require similar precautions. As such, buildings should be designed in a way that facilitates safe maintenance, possibly with built-in anchor points for harnesses or designated access paths.

Conservation Areas and Listed Buildings

Conservation areas are zones designated by local planning authorities due to their special architectural or historic interest. Changes in these areas are more controlled to ensure the character and appearance of the locale are preserved. Listed buildings, on the other hand, are individually marked for their historic or architectural significance. As such, they are protected by law against unsanctioned alterations. In the UK, any alteration to a listed building or a structure in a conservation area generally requires special permissions. This includes the addition of EWI. Before undertaking any work, it's crucial to consult with the local planning authority to understand what's permissible and what might require specific approval.

Striking the Balance with EWI:

- Aesthetics: One of the main concerns with adding EWI to historic structures is the potential change in appearance. Solutions might include using materials that mimic the original facade. Alternatively, placing insulation internally to avoid external changes is an option.

- Material Compatibility: Historic buildings often use traditional materials like lime plaster or timber. Introducing modern insulating materials needs careful consideration to ensure compatibility, preventing unforeseen reactions or damage over time.

- Preserving Features: Historic structures often have unique architectural features. EWI installations should be done in a way that these features remain intact and visible, preserving the building's character.

While challenges exist, it's essential to understand the benefits of introducing EWI. Proper insulation can protect the building from moisture, reduce energy costs, and improve indoor comfort, ensuring the structure remains usable and relevant in today's context.

Drainage and Water Absorption

Water, whether from rain, condensation, or other sources, can compromise the integrity and effectiveness of EWI systems. It can lead to mould growth, reduce insulation efficiency, and even cause structural damage if not adequately managed. In the UK, Building Regulations Part C emphasises safeguarding buildings from moisture from the ground and other sources. These regulations provide guidance on ensuring that buildings remain dry and resistant to moisture ingress, which is pertinent when installing EWI.

Key Considerations for Drainage and Water Absorption:

- Surface Water Drainage: EWI systems should be designed to direct rainwater and other surface water away from the building. This might include features like drip edges or channels that prevent water from seeping behind the insulation.

- Water-Resistant Materials: Materials used in EWI systems should be resistant to water absorption. However, they should also allow for breathability, permitting trapped moisture to evaporate.

- Waterproofing Membranes: Incorporating waterproof or water-resistant membranes behind the EWI can act as an additional barrier, preventing moisture from reaching the building's substrate.

- Breathability: While preventing water ingress is essential, it's equally crucial to ensure that any moisture trapped behind the EWI can escape. Breathable materials and systems help maintain a dry, healthy building envelope.

- Base Profiles: At the bottom of EWI systems, specially designed profiles can be installed to ensure that water drips away from the building's foundation. This prevents pooling and potential seepage.

Over time, even the most robust EWI systems can experience wear and tear. Regular inspections can identify potential issues like cracks, gaps, or areas of water accumulation. Addressing these promptly ensures the longevity and effectiveness of the EWI system. Buildings in areas prone to heavy rainfall, high humidity, or coastal environments might need special considerations in their EWI design to handle the increased moisture exposure. EWI doesn't function in isolation. It needs to be effectively integrated with other building systems like guttering, downpipes, and ventilation to ensure holistic moisture management.

Sound Insulation

Sound travels in waves and can pass through different mediums, including air and solid structures. Its transmission can be reduced by introducing barriers or materials that absorb or reflect these waves, thereby dampening the sound. In the UK, Building Regulations Part E specifically focuses on ensuring adequate sound insulation between buildings and different sections of the same building. While it primarily addresses internal noise transfer, the principles can be applied to EWI to boost its sound insulation properties.

Key Considerations for Sound Insulation in EWI:

- Dense Materials: Dense and heavy materials naturally impede the transfer of sound waves. Materials such as stone wool or certain mineral wool add both thermal and acoustic insulation.

- Absorptive Layers: Introducing layers that can absorb sound waves, rather than merely reflecting them, can further reduce noise intrusion. Some modern insulation materials are designed with open cellular structures that can trap and absorb sound waves effectively.

- Decoupling: This involves introducing a gap or break in the building structure to disrupt the path of sound waves. For instance, an insulated cavity can be introduced between the building's main wall and the EWI to provide a break in the sound path.

- Sealing Gaps and Cracks: Sound, much like air, can infiltrate through the smallest of openings. Ensuring that the EWI system is meticulously sealed will prevent these potential sound leaks.

Enhanced sound insulation can offer benefits beyond merely reducing noise. It can enhance privacy within homes or offices, improve sleep quality by reducing nighttime disturbances, and even increase property values in noisy urban areas. In areas prone to specific noise sources, like airports, railways, or bustling commercial districts, targeted sound insulation strategies might be required. This could involve the use of specialized acoustic materials or designs tailored to counter specific frequencies. While EWI can significantly reduce noise transmission through walls, windows and ventilation systems can often become weak points for sound intrusion. Therefore, to maximise sound insulation, it might be necessary to consider upgrading windows to double or triple glazing. Also, ensure that ventilation systems have built-in acoustic dampening.

Appearance

EWI offers a fantastic opportunity for homeowners, architects, and developers to update, refresh, or entirely redesign the exterior appearance of a structure.EWI doesn't have to mean a loss of a building's unique features. Elements like cornices, lintels, sills, or decorative mouldings can be retained or recreated using modern materials, ensuring that the building's character remains intact. In areas with historical significance or within designated conservation zones, there may be restrictions on the types of finishes or colours permissible to maintain the area's character. In some regions or housing developments, there's a prevailing aesthetic. While individuality is valuable, it's also essential to ensure that the EWI doesn't make the building jarringly stand out. This can potentially impact community harmony or even property values. The appearance of EWI isn't just about the initial installation; it's also about how it ages. Materials chosen should be durable, resistant to fading from UV exposure, and easy to clean or maintain. Reflective finishes or light colours might be preferred in hot climates as they can reflect sunlight. Conversely, in colder regions, darker hues might be selected to absorb more sunlight.

Access and Facilities for the Disabled

Inclusive design ensures that buildings and public spaces are accessible and usable by everyone, irrespective of their physical abilities. This principle promotes equality, diversity, and social inclusion. In the UK, Building Regulations Part M provides guidelines for making buildings more accessible and user-friendly for disabled people. When applying EWI, it's essential to ensure that the changes made to the building's exterior do not hinder or restrict access as outlined in these regulations. Key Considerations for Access and Facilities in EWI Projects:

- Ramps and Level Access: If EWI installation changes the height of the building's exterior, ensure that ramps or level access points are appropriately adjusted to accommodate these changes, allowing wheelchair users to enter and exit the building easily.

- Handrails and Grab Bars: Any changes to the building's structure shouldn't interfere with the placement or usability of handrails and grab bars. If they do, these should be repositioned or redesigned accordingly.

- Width of Pathways and Doorways: Ensure that the insulation doesn't narrow pathways or doorways to the extent that they become difficult for wheelchair users or people with mobility aids to navigate.

- Tactile Paving: For visually impaired individuals, tactile paving is vital. If EWI modifications affect areas with tactile paving (like entrances), they need to be appropriately restored or re-laid.

- Signage: EWI projects might sometimes obscure or relocate building signage. Ensure that signage, especially those indicating accessible routes or facilities, is clear, visible, and placed at an appropriate height.

- Emergency Exits: Safety is paramount. Any EWI work must not block or reduce the width of emergency exits. Furthermore, adjustments might be needed to ensure disabled individuals can safely evacuate in emergencies.

- Parking: If your EWI affects the exterior to the extent that it impacts parking, ensure that designated disabled parking spots remain accessible and are clearly marked.