4.8 out of 5 Stars on TrustPilot

How Do I Attach Satellites & Washing Lines to EWI?

Installing an EWI system will add upwards of 100mm to the thickness of external walls. A question often posed to us is ‘How do I attach satellites & washing lines to EWI?’ At the EWI Store, we hold a very close partnership with SWIFIX. The SWIFIX system is a completely innovative and patented solution. The SWIFIX mission statement summarises the solutions their system provides:

“Our products are one of the most cost-effective solutions to enable the fitting of external furniture through external wall insulation and rain screen cladding, with the added benefit of being designed specifically for the job. Fully PAS2035 complaint for the future of retrofitting and the Modular housing sectors and the ideal solution for a longer-term maintenance provision.

All fittings meet stringent technical requirements by preventing the compression of insulation and providing a watertight seal. They are also approved by many leading manufacturers and organisations developing modern methods of construction to support the requirement for new homes in the UK.

We are confident that our products are the most innovative on the market as well as being cost-effective. They are a highly robust and technical fixing that is easy to install as well as providing a maintenance solution.”

(SWIFIX)

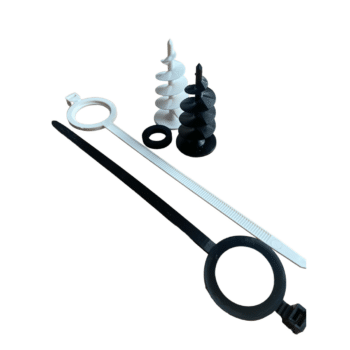

Spiral anchors

Spiral anchors, when used in the context of External Wall Insulation (EWI) systems, are often used for attaching lightweight items to the insulated facade, not for the insulation itself. These lightweight items might include things like downpipes, cable trays, signs, or decorative elements. As they are usually plastic fittings, the recommended load is around 5kg per fixings. However, they require no special tools and also create no thermal bridges.

The process for installing these anchors for lightweight items will follow these steps:

- Mark the location – Determine where the lightweight item will be placed on the EWI surface.

- Drill a pilot hole – Drill a hole through the insulation and into the underlying substrate at the marked location. The depth and diameter of the hole should match the specifications of the spiral anchor. It is crucial to note that not all render finishes require a pilot hole. Thin coat systems do not require one and you can screw the spiral anchor directly into the insulation.

- Insert the spiral anchor – Place the spiral anchor into the hole. Ensure it goes through the insulation and securely into the substrate.

- Screw in the anchor – Use a suitable tool to screw the anchor into the substrate until it’s secure. After the fixing has been initially fitted, a mastic seal must be placed around the last thread section before final tightening. Standard external grade screws can then be used (up to 50mm embedment) for securing lightweight fixtures and fittings.

- Attach the item – Once the anchor is secure, you can attach the lightweight item to the anchor. This may involve screwing the item onto the exposed end of the anchor, or it might involve some other method of attachment, depending on the specifics of the item and the anchor.

SWIFIX and their solutions to attach items to EWI

The standard method for fixing items through EWI has relied on timber patresses. A timber patress, also known as a pattress or a patress plate, is a flat piece of timber that is used in construction to spread the load of a fixing or fixture over a larger area. This helps to prevent damage to the wall and ensures that the fixture is securely attached.

In the context of External Wall Insulation (EWI), a timber patress is often used when attaching heavier fixtures to the wall. The fixture, such as a satellite dish or an awning, is attached to the timber patress, and the patress is then fixed to the wall, spreading the load over a larger area of the wall.

SWIFIX developed their range of fixings to solve the issues timber patresses pose. As they are manufactured from timber, they are prone to failure. However, SWIFIX fixings are manufactured from PVC, which costs less and is technically more appropriate for EWI systems.

Connection point fitting

The connection point fitting is incredibly versatile. It can be used to secure cables, attach washing lines, hang baskets, and affix utility cables to existing substrates. The marine-grade stainless steel eye bolt ensures that the attachment point is incredibly durable. Moreover, the design of the fitting ensures that the seal is watertight and does not require mastic. As the fitting goes directly through the EWI system, thermal bridging is also minimised.

Tap fitting

A SWIFIX tap fitting is the premier solution to fitting an external tap on your EWI system. The design of the fittings ensures a watertight seal. SWIFIX fixings are designed to eliminate the risk of cold spots and water ingress when installing fixings; this ensures that the system remains functioning optimally and that the thermal efficiency of the system is maintained. Crucially, the systems are tested by the British Research Institute for strength, compression, and load-bearing capabilities.

Satellite fitting plate

The satellite fitting player completely eliminates the need for timber. A satellite dish will require refitting following the installation of an EWI system. With a SWIFIX satellite fitting plate, the installation will have a watertight seal, as well as distribute the weight of the satellite across the plate.

Pipe connector

The SWIFIX Pipe Connector provides a robust and secure fitting for various sizes of pipework. Ideal for gas, rainwater and items that require a secure and rigid fixing. It is fitted through external wall insulation to the existing substrate, providing a watertight seal without the need for mastic.

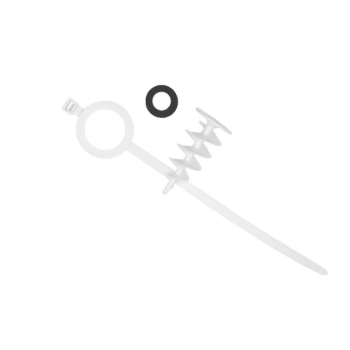

External wall cable connectors

The external wall cable connectors were developed by SWIFIX in response to a customer’s issue with affixing cables. The system combines a unique interlocking system, preventing the over-tightening of the spiral anchor, as well as maintaining the correct angle for cabling. The neoprene washer ensures a watertight seal. Using the cable tie element in conjunction with the SWIFIX Single Tube allows the securing of heavier items, such as commercial cables and lightning conductors, to be secured back to the substrate independently from the insulated system.

-

Swifix Connection Point Fitting

From £9.95 Incl. VATFrom £8.29 Excl. VAT -

Swifix External Wall Cable Connectors

From £16.20 Incl. VATFrom £13.50 Excl. VAT -

Swifix Satellite Plate Fitting

From £15.59 Incl. VATFrom £12.99 Excl. VAT -

Swifix Tap Fitting

From £7.55 Incl. VATFrom £6.29 Excl. VAT

The major benefit of using SWIFIX fittings to attach to EWI is the prevention of water ingress. Water ingress is the scourge of most building assemblies, and this includes EWI systems. Water can travel behind fittings that do not sit flush, or behind insulation boards. This is why verge trims are also crucial to prevent water ingress. New regulations dictate that verge trims require a secondary waterproof membrane to supplement the actual trim. All of this feeds into the whole waterproofing of the system.

Have you recently used SWIFIX fixings to attach items to EWI? If so, let us know about your experiences below. If you have any other questions, leave them below also!

Facebook

Twitter

LinkedIn

Your cart

Trade Account Login

We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. By clicking “Accept All”, you consent to the use of ALL the cookies. However, you may visit "Cookie Settings" to provide personalised consent.

Manage consent

Privacy Overview

This website uses cookies to improve your experience while you navigate through the website. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. We also use third-party cookies that help us analyze and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may affect your browsing experience.

Necessary cookies are absolutely essential for the website to function properly. These cookies ensure basic functionalities and security features of the website, anonymously.

| Cookie | Duration | Description |

|---|---|---|

| __stripe_mid | 1 year | This cookie is set by Stripe payment gateway. This cookie is used to enable payment on the website without storing any patment information on a server. |

| __stripe_sid | 30 minutes | This cookie is set by Stripe payment gateway. This cookie is used to enable payment on the website without storing any patment information on a server. |

| _GRECAPTCHA | 5 months 27 days | This cookie is set by the Google recaptcha service to identify bots to protect the website against malicious spam attacks. |

| apbct_cookies_test | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_page_hits | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_prev_referer | session | Functional cookie placed by CleanTalk Spam Protect to store referring IDs and prevent unauthorized spam from being sent from the website. |

| apbct_site_landing_ts | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_site_referer | 3 days | This cookie is placed by CleanTalk Spam Protect to prevent spam and to store the referrer page address which led the user to the website. |

| apbct_timestamp | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_urls | 3 days | This cookie is placed by CleanTalk Spam Protect to prevent spam and to store the addresses (urls) visited on the website. |

| AWSALBCORS | 7 days | This cookie is managed by Amazon Web Services and is used for load balancing. |

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| ct_checkjs | session | CleanTalk–Used to prevent spam on our comments and forms and acts as a complete anti-spam solution and firewall for this site. |

| ct_fkp_timestamp | session | CleanTalk sets this cookie to prevent spam on the site's comments/forms, and to act as a complete anti-spam solution and firewall for the site. |

| ct_pointer_data | session | CleanTalk sets this cookie to prevent spam on the site's comments/forms, and to act as a complete anti-spam solution and firewall for the site. |

| ct_ps_timestamp | session | CleanTalk sets this cookie to prevent spam on the site's comments/forms, and to act as a complete anti-spam solution and firewall for the site. |

| ct_sfw_pass_key | 1 month | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| ct_timezone | session | CleanTalk–Used to prevent spam on our comments and forms and acts as a complete anti-spam solution and firewall for this site. |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features.

| Cookie | Duration | Description |

|---|---|---|

| __zlcmid | 1 year | This cookie is used by Zendesk live chat and is used to store the live chat ID. |

| bcookie | 2 years | LinkedIn sets this cookie from LinkedIn share buttons and ad tags to recognize browser ID. |

| bscookie | 2 years | LinkedIn sets this cookie to store performed actions on the website. |

| lang | session | LinkedIn sets this cookie to remember a user's language setting. |

| lidc | 1 day | LinkedIn sets the lidc cookie to facilitate data center selection. |

| UserMatchHistory | 1 month | LinkedIn sets this cookie for LinkedIn Ads ID syncing. |

Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.

| Cookie | Duration | Description |

|---|---|---|

| __utma | 2 years | This cookie is set by Google Analytics and is used to distinguish users and sessions. The cookie is created when the JavaScript library executes and there are no existing __utma cookies. The cookie is updated every time data is sent to Google Analytics. |

| __utmb | 30 minutes | Google Analytics sets this cookie, to determine new sessions/visits. __utmb cookie is created when the JavaScript library executes and there are no existing __utma cookies. It is updated every time data is sent to Google Analytics. |

| __utmc | session | The cookie is set by Google Analytics and is deleted when the user closes the browser. It is used to enable interoperability with urchin.js, which is an older version of Google Analytics and is used in conjunction with the __utmb cookie to determine new sessions/visits. |

| __utmt | 10 minutes | Google Analytics sets this cookie to inhibit request rate. |

| __utmv | 2 years | The __utmv cookie is set on the user's device, to enable Google Analytics to classify the visitor. |

| __utmz | 6 months | Google Analytics sets this cookie to store the traffic source or campaign by which the visitor reached the site. |

| sib_cuid | 6 months | Purechat uses this cookie to send data to purechat.com, to connect visitors to the reservation team and track visitors to stay on portal. |

| SRM_B | 1 year 24 days | Used by Microsoft Advertising as a unique ID for visitors. |

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc.

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _gat_gtag_UA_61069204_2 | 1 minute | Set by Google to distinguish users. |

| _gat_UA-61069204-2 | 1 minute | A variation of the _gat cookie set by Google Analytics and Google Tag Manager to allow website owners to track visitor behaviour and measure site performance. The pattern element in the name contains the unique identity number of the account or website it relates to. |

| _gcl_au | 3 months | Provided by Google Tag Manager to experiment advertisement efficiency of websites using their services. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| _uetsid | 1 day | This cookies are used to collect analytical information about how visitors use the website. This information is used to compile report and improve site. |

| CONSENT | 2 years | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. These cookies track visitors across websites and collect information to provide customized ads.

| Cookie | Duration | Description |

|---|---|---|

| _fbp | 3 months | This cookie is set by Facebook to display advertisements when either on Facebook or on a digital platform powered by Facebook advertising, after visiting the website. |

| ANONCHK | 10 minutes | The ANONCHK cookie, set by Bing, is used to store a user's session ID and also verify the clicks from ads on the Bing search engine. The cookie helps in reporting and personalization as well. |

| fr | 3 months | Facebook sets this cookie to show relevant advertisements to users by tracking user behaviour across the web, on sites that have Facebook pixel or Facebook social plugin. |

| MUID | 1 year 24 days | Bing sets this cookie to recognize unique web browsers visiting Microsoft sites. This cookie is used for advertising, site analytics, and other operations. |

| NID | 6 months | NID cookie, set by Google, is used for advertising purposes; to limit the number of times the user sees an ad, to mute unwanted ads, and to measure the effectiveness of ads. |

| test_cookie | 15 minutes | The test_cookie is set by doubleclick.net and is used to determine if the user's browser supports cookies. |

| uuid | 6 months | MediaMath sets this cookie to avoid the same ads from being shown repeatedly and for relevant advertising. |

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt-remote-device-id | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt.innertube::nextId | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |

| yt.innertube::requests | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |

Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet.

| Cookie | Duration | Description |

|---|---|---|

| _clck | 1 year | No description |

| _clsk | 1 day | No description |

| _uetvid | 1 year 24 days | No description available. |

| AnalyticsSyncHistory | 1 month | No description |

| apbct_pixel_url | session | No description |

| apbct_visible_fields_0 | session | No description |

| apbct_visible_fields_1 | session | No description |

| apbct_visible_fields_10 | session | No description |

| apbct_visible_fields_2 | session | No description |

| apbct_visible_fields_3 | session | No description |

| apbct_visible_fields_4 | session | No description |

| apbct_visible_fields_5 | session | No description |

| apbct_visible_fields_6 | session | No description |

| apbct_visible_fields_7 | session | No description |

| apbct_visible_fields_8 | session | No description |

| apbct_visible_fields_9 | session | No description |

| ct_checked_emails | session | No description |

| ct_has_scrolled | session | No description |

| ct_mouse_moved | session | No description |

| ct_screen_info | session | No description |

| ictf_master | never | No description available. |

| li_gc | 2 years | No description |

| m | 2 years | No description available. |

| SM | session | No description available. |

| testinfinitycookie | session | No description |

| woocommerce_show_tax | 7 days | No description available. |

| wp_woocommerce_session_c5ac76b408021294cb56bcc27eddf8a1 | 2 days | No description |

2 thoughts on “How Do I Attach Satellites & Washing Lines to EWI?”

What are the issues if the tap is not installed correctly on the insulation?

Hi Dan, the major issue would be water ingress into and then behind the insulation.