4.8 out of 5 Stars on TrustPilot

Complete Guide To Drywall Screws

Drywall, also known as gypsum board or wallboard, is a building material used to construct walls and ceilings in residential and commercial buildings. It is made of gypsum, a soft sulfate mineral composed of calcium sulfate dihydrate, which is sandwiched between two sheets of heavy paper or fiberglass.

Drywall is widely used because of its ease of installation, durability, and fire resistance. It is available in different thicknesses, from 9mm to 25mm.

The main benefit of drywall is that it is relatively cheap and easy to install. It can be cut to size using a utility knife and attached to wood or metal framing using drywall screws.

Unfortunately, there are loads of different types of drywall screws so in this blog we are going to try to explain the difference between them so you know which ones to use on your next job!

Zinc Coated Drywall Screws versus Black Phosphate Drywall Screws

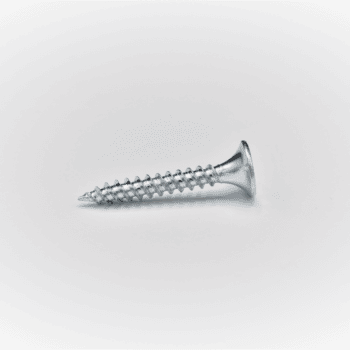

Zinc-coated drywall screws (often referred to as BZP drywall screws) are screws that have been coated with a layer of zinc to protect them from rust and corrosion. Black phosphate drywall screws are screws that have been coated with a black phosphate finish.

The main difference between the two is the type of coating used. Zinc coating provides a higher level of corrosion resistance than black phosphate coating, but black phosphate coating provides a better grip and can be more visually appealing. Additionally, black phosphate coating is generally less expensive than zinc coating.

Why use Black Phosphate drywall screws

Black phosphate drywall screws are used for a variety of reasons, including:

- Aesthetics: The black colour of the screws can blend in better with the surrounding surface, making them less noticeable.

- Grip: The black phosphate coating provides a better grip than zinc coating, which can make it easier to drive the screws into the drywall.

- Cost: Black phosphate coating is generally less expensive than zinc coating, making it a more cost-effective option.

- Resistance: Black phosphate coating provides a moderate level of resistance to corrosion, which is suitable for indoor use.

- Compatibility: Black phosphate coating is compatible with a variety of materials and substrates, making it a versatile option.

Why use Zinc Coated Drywall Screws

Zinc-coated drywall screws are used for a variety of reasons, including:

- Corrosion resistance: Zinc coating provides a higher level of corrosion resistance than black phosphate coating, making it a better option for outdoor or high-moisture environments.

- Durability: Zinc coating is known to be more durable than black phosphate coating, which can make the screws last longer.

- Aesthetics: Zinc coating can be used to match the colour of the surrounding surface, making the screws less noticeable.

- Compatibility: Zinc coating is compatible with a variety of materials and substrates, making it a versatile option.

Cost-effectiveness: Zinc coating is more expensive than black phosphate coating, but because of its corrosion resistance and durability, it can be considered a cost-effective solution in the long run.

- Sources

Fine thread Drywall screws versus coarse thread drywall screws

Fine thread drywall screws and coarse thread drywall screws are different in terms of the thread pitch, which is the distance between the threads on the screw.

Coarse thread drywall screws have a wider thread pitch, meaning the threads are farther apart. This makes them better for gripping into softer materials like drywall, and they are typically used for attaching drywall to wood studs.

Fine thread drywall screws have a narrower thread pitch, meaning the threads are closer together. This makes them better for gripping into harder materials like metal studs, and they are typically used for attaching drywall to metal studs or other harder surfaces.

In general, coarse thread drywall screws are considered to be stronger than fine thread screws, and they can provide a more secure grip in wood. On the other hand, fine thread drywall screws are considered to be more precise and accurate, and they can be less likely to damage the material they are being driven into.

In summary, the choice between fine or coarse thread drywall screws depends on the type of material you will be attaching the drywall to, and the level of precision and grip you require.

-

BP Coarse Thread Drywall Screws

From £1.78 Incl. VATFrom £1.48 Excl. VAT -

BP Fine Thread Drywall Screws

From £1.78 Incl. VATFrom £1.48 Excl. VAT -

BZP Fine Thread Drywall Screws

Rated 5.00 out of 5From £6.89 Incl. VATFrom £5.74 Excl. VAT

What is a Bugle Drywall Screw

A bugle drywall screw is a type of drywall screw that has a unique head shape known as a “bugle head.” The bugle head has a wider, flatter surface than a traditional drywall screw, which allows it to sit flush against the surface of the drywall. This design helps to prevent the drywall from cracking or splitting when the screw is driven in, and allows for a smoother finish.

Bugle head drywall screws are typically used in conjunction with drywall anchors and are inserted into the drywall and then the anchor is inserted into the hole created by the screw. The screw is tightened, pulling the anchor flush against the back of the drywall. This creates a strong and secure hold without the need to locate a stud.

Another advantage of using bugle head drywall screws is that the bugle head provides a larger bearing surface, which distributes the clamping force over a larger area and reduces the chance of the drywall cracking or breaking.

In summary, bugle head drywall screws are used to attach drywall to wood or metal studs, or to other materials using anchors. They are designed to sit flush against the surface of the drywall, preventing cracking and providing a smooth finish.

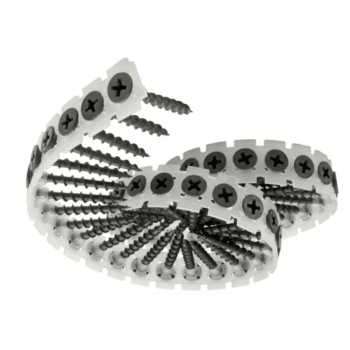

What are Collated Drywall Screws

Collated drywall screws are drywall screws that are attached to a strip or sheet of material, known as a collation. The collation keeps the screws in a specific order and spacing, making them easier to handle and use.

Collated drywall screws are typically used in conjunction with a collated screw gun, which is a power tool that automatically feeds the screws from the collation into the gun, allowing the user to drive the screws quickly and easily into the drywall. This can be especially useful for large drywall installation projects where many screws need to be inserted in a short period of time.

Collated drywall screws come in a variety of lengths, thread types, and head types. They are available in a variety of packaging, like strips, coils, or plastic cases. They are also available in different types of collation, like paper, plastic, or wire coil.

The main advantage of collated drywall screws is that they allow for faster and more efficient installation of drywall, as the user does not need to manually handle and place each individual screw. Additionally, collated drywall screws are less prone to dropping or losing screws, which can save time and reduce the risk of injury.

In summary, collated drywall screws are drywall screws that are attached to a strip or sheet of material called a collation, designed to be used with a collated screw gun. They allow for faster and more efficient installation of drywall and reduce the risk of losing or dropping screws.

-

BP Collated Drywall Screws

From £15.18 Incl. VATFrom £12.65 Excl. VAT

Optimum Length of Drywall screws

The optimum length for a drywall screw in millimeters (mm) depends on several factors, including the thickness of the drywall, the type of material the drywall is being attached to, and the desired level of grip.

For attaching 12.5mm (1/2″) drywall to wood studs, a 32mm to 38mm long drywall screw is generally considered to be the best choice. This length allows the screw to grip securely into the stud, while not penetrating through the other side of the drywall.

For attaching 15.9mm (5/8″) drywall to wood studs, a 44mm to 51mm long drywall screw is generally considered to be the best choice.

For attaching drywall to metal studs, a 32mm to 38mm long drywall screw is generally considered to be the best choice.

When using drywall anchors, it is recommended to use 32mm to 38mm long drywall screws.

As a reminder, it is always better to use slightly longer screws than shorter screws, as longer screws provide a better grip and are less likely to pull out over time.

Buy Drywall Screws from EWI Store!

EWI Store offers a huge range of drywall screws at unbeatable prices.

Facebook

Twitter

LinkedIn

Your cart

Trade Account Login

We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. By clicking “Accept All”, you consent to the use of ALL the cookies. However, you may visit "Cookie Settings" to provide personalised consent.

Manage consent

Privacy Overview

This website uses cookies to improve your experience while you navigate through the website. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. We also use third-party cookies that help us analyze and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may affect your browsing experience.

Necessary cookies are absolutely essential for the website to function properly. These cookies ensure basic functionalities and security features of the website, anonymously.

| Cookie | Duration | Description |

|---|---|---|

| __stripe_mid | 1 year | This cookie is set by Stripe payment gateway. This cookie is used to enable payment on the website without storing any patment information on a server. |

| __stripe_sid | 30 minutes | This cookie is set by Stripe payment gateway. This cookie is used to enable payment on the website without storing any patment information on a server. |

| _GRECAPTCHA | 5 months 27 days | This cookie is set by the Google recaptcha service to identify bots to protect the website against malicious spam attacks. |

| apbct_cookies_test | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_page_hits | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_prev_referer | session | Functional cookie placed by CleanTalk Spam Protect to store referring IDs and prevent unauthorized spam from being sent from the website. |

| apbct_site_landing_ts | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_site_referer | 3 days | This cookie is placed by CleanTalk Spam Protect to prevent spam and to store the referrer page address which led the user to the website. |

| apbct_timestamp | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_urls | 3 days | This cookie is placed by CleanTalk Spam Protect to prevent spam and to store the addresses (urls) visited on the website. |

| AWSALBCORS | 7 days | This cookie is managed by Amazon Web Services and is used for load balancing. |

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| ct_checkjs | session | CleanTalk–Used to prevent spam on our comments and forms and acts as a complete anti-spam solution and firewall for this site. |

| ct_fkp_timestamp | session | CleanTalk sets this cookie to prevent spam on the site's comments/forms, and to act as a complete anti-spam solution and firewall for the site. |

| ct_pointer_data | session | CleanTalk sets this cookie to prevent spam on the site's comments/forms, and to act as a complete anti-spam solution and firewall for the site. |

| ct_ps_timestamp | session | CleanTalk sets this cookie to prevent spam on the site's comments/forms, and to act as a complete anti-spam solution and firewall for the site. |

| ct_sfw_pass_key | 1 month | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| ct_timezone | session | CleanTalk–Used to prevent spam on our comments and forms and acts as a complete anti-spam solution and firewall for this site. |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features.

| Cookie | Duration | Description |

|---|---|---|

| __zlcmid | 1 year | This cookie is used by Zendesk live chat and is used to store the live chat ID. |

| bcookie | 2 years | LinkedIn sets this cookie from LinkedIn share buttons and ad tags to recognize browser ID. |

| bscookie | 2 years | LinkedIn sets this cookie to store performed actions on the website. |

| lang | session | LinkedIn sets this cookie to remember a user's language setting. |

| lidc | 1 day | LinkedIn sets the lidc cookie to facilitate data center selection. |

| UserMatchHistory | 1 month | LinkedIn sets this cookie for LinkedIn Ads ID syncing. |

Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.

| Cookie | Duration | Description |

|---|---|---|

| __utma | 2 years | This cookie is set by Google Analytics and is used to distinguish users and sessions. The cookie is created when the JavaScript library executes and there are no existing __utma cookies. The cookie is updated every time data is sent to Google Analytics. |

| __utmb | 30 minutes | Google Analytics sets this cookie, to determine new sessions/visits. __utmb cookie is created when the JavaScript library executes and there are no existing __utma cookies. It is updated every time data is sent to Google Analytics. |

| __utmc | session | The cookie is set by Google Analytics and is deleted when the user closes the browser. It is used to enable interoperability with urchin.js, which is an older version of Google Analytics and is used in conjunction with the __utmb cookie to determine new sessions/visits. |

| __utmt | 10 minutes | Google Analytics sets this cookie to inhibit request rate. |

| __utmv | 2 years | The __utmv cookie is set on the user's device, to enable Google Analytics to classify the visitor. |

| __utmz | 6 months | Google Analytics sets this cookie to store the traffic source or campaign by which the visitor reached the site. |

| sib_cuid | 6 months | Purechat uses this cookie to send data to purechat.com, to connect visitors to the reservation team and track visitors to stay on portal. |

| SRM_B | 1 year 24 days | Used by Microsoft Advertising as a unique ID for visitors. |

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc.

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _gat_gtag_UA_61069204_2 | 1 minute | Set by Google to distinguish users. |

| _gat_UA-61069204-2 | 1 minute | A variation of the _gat cookie set by Google Analytics and Google Tag Manager to allow website owners to track visitor behaviour and measure site performance. The pattern element in the name contains the unique identity number of the account or website it relates to. |

| _gcl_au | 3 months | Provided by Google Tag Manager to experiment advertisement efficiency of websites using their services. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| _uetsid | 1 day | This cookies are used to collect analytical information about how visitors use the website. This information is used to compile report and improve site. |

| CONSENT | 2 years | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. These cookies track visitors across websites and collect information to provide customized ads.

| Cookie | Duration | Description |

|---|---|---|

| _fbp | 3 months | This cookie is set by Facebook to display advertisements when either on Facebook or on a digital platform powered by Facebook advertising, after visiting the website. |

| ANONCHK | 10 minutes | The ANONCHK cookie, set by Bing, is used to store a user's session ID and also verify the clicks from ads on the Bing search engine. The cookie helps in reporting and personalization as well. |

| fr | 3 months | Facebook sets this cookie to show relevant advertisements to users by tracking user behaviour across the web, on sites that have Facebook pixel or Facebook social plugin. |

| MUID | 1 year 24 days | Bing sets this cookie to recognize unique web browsers visiting Microsoft sites. This cookie is used for advertising, site analytics, and other operations. |

| NID | 6 months | NID cookie, set by Google, is used for advertising purposes; to limit the number of times the user sees an ad, to mute unwanted ads, and to measure the effectiveness of ads. |

| test_cookie | 15 minutes | The test_cookie is set by doubleclick.net and is used to determine if the user's browser supports cookies. |

| uuid | 6 months | MediaMath sets this cookie to avoid the same ads from being shown repeatedly and for relevant advertising. |

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt-remote-device-id | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt.innertube::nextId | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |

| yt.innertube::requests | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |

Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet.

| Cookie | Duration | Description |

|---|---|---|

| _clck | 1 year | No description |

| _clsk | 1 day | No description |

| _uetvid | 1 year 24 days | No description available. |

| AnalyticsSyncHistory | 1 month | No description |

| apbct_pixel_url | session | No description |

| apbct_visible_fields_0 | session | No description |

| apbct_visible_fields_1 | session | No description |

| apbct_visible_fields_10 | session | No description |

| apbct_visible_fields_2 | session | No description |

| apbct_visible_fields_3 | session | No description |

| apbct_visible_fields_4 | session | No description |

| apbct_visible_fields_5 | session | No description |

| apbct_visible_fields_6 | session | No description |

| apbct_visible_fields_7 | session | No description |

| apbct_visible_fields_8 | session | No description |

| apbct_visible_fields_9 | session | No description |

| ct_checked_emails | session | No description |

| ct_has_scrolled | session | No description |

| ct_mouse_moved | session | No description |

| ct_screen_info | session | No description |

| ictf_master | never | No description available. |

| li_gc | 2 years | No description |

| m | 2 years | No description available. |

| SM | session | No description available. |

| testinfinitycookie | session | No description |

| woocommerce_show_tax | 7 days | No description available. |

| wp_woocommerce_session_c5ac76b408021294cb56bcc27eddf8a1 | 2 days | No description |

4 thoughts on “Complete Guide To Drywall Screws ”

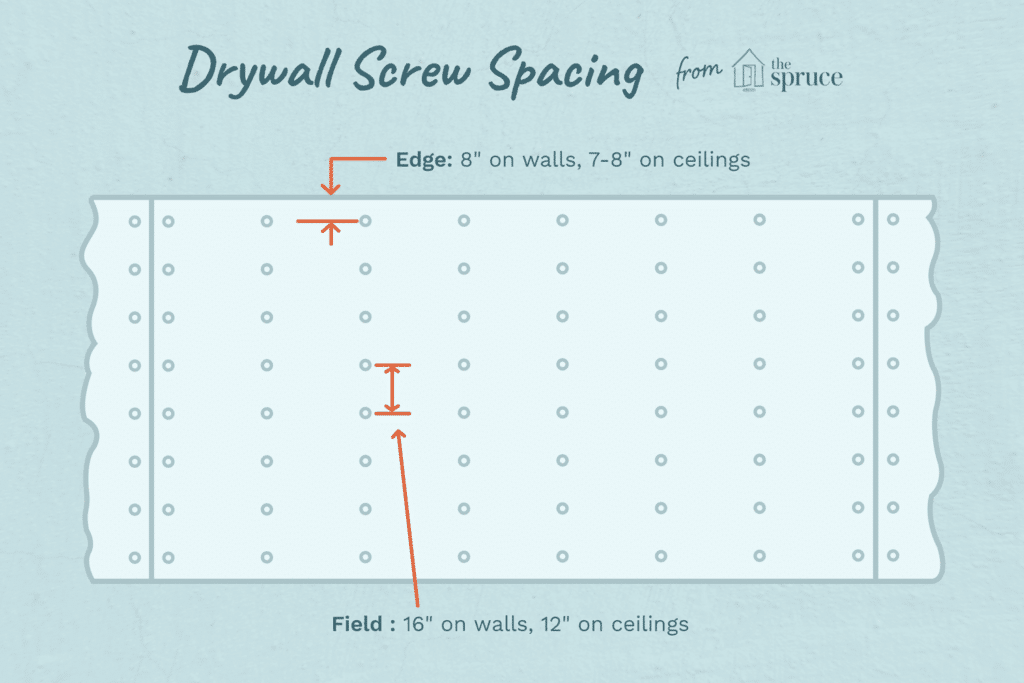

How many drywall screws do you use for each 2400 x 1200 board. We have spaced battens at 400mm but not sure how many screws we need per batten.

Thanks

Kev

Hi Kev, so put the boards on the wall landscape, and there should be 5 screws per batten (so one every 12 inches / 30cm).

Why do some people attach to battens and others just dot and dab drywall? Is it just to straighten a pissed wall?

Get a drywall collated gun. Easiest way!