Why is Expanding Foam Tape so Important in EWI Systems?

Expanding foam tape is an often overlooked yet essential component in External Wall Insulation (EWI) systems. It plays a crucial role in maintaining the integrity, thermal efficiency, and longevity of an EWI installation. Let’s explore why expanding foam tape is so important, where it should be used, its benefits, and how to install it effectively to ensure the best performance.

What is Expanding Foam Tape?

Expanding foam tape, or pre-compressed foam tape, is a flexible, foam-based sealing material designed to expand and fill gaps or joints. Typically made from polyurethane or similar foam, the tape is compressed during manufacturing. It expands to fill spaces when applied, providing an adaptable, tight seal. It’s highly resistant to moisture, UV rays, and temperature changes, making it ideal for areas exposed to the elements, such as around windows, doors, and roofing components.

Unlike silicone, which can break down over time, expanding foam tape maintains its structure and flexibility, accommodating any natural expansion and contraction of the building materials. Expanding foam tape is used in various places within an EWI system, including between insulation boards, around window frames and sills, and at the roofline. It prevents thermal bridging, stops water ingress, and creates a stable seal across these vulnerable points. Expanding foam tape typically has a lifespan of up to 30 years, making it a durable option compared to other sealing materials like silicone, which may degrade within a decade.

-

Lynvale – Expanding Foam Tape – 5.6m (15mm)

£15.65 Incl. VAT£13.04 Excl. VAT

Why is Expanding Foam Tape so important in EWI systems?

Preventing water ingress

- Full-Surface Contact: When applied, expanding foam tape fills gaps and joints entirely by expanding to conform to irregular surfaces, creating a seamless, continuous barrier. This eliminates any potential paths for water to penetrate, even in areas with uneven textures or small crevices that are hard to seal with traditional methods.

- Compression-Based Seal: Foam tape is installed in a compressed state. As it expands, it pushes tightly against adjacent surfaces, forming a barrier that resists contaminants.

- Long-Term Moisture Resistance: Unlike other sealants, expanding foam tape is typically made from closed-cell foam, which has a water-resistant structure that naturally repels water. This closed-cell composition prevents the tape from absorbing moisture, which could otherwise compromise the seal.

- Adaptability to Movement: Expanding foam tape can flex and move with the building’s natural expansion and contraction due to temperature and environmental changes. This flexibility ensures the seal remains intact over time, reducing the risk of cracks or gaps that water could infiltrate. In contrast, rigid sealants like silicone can crack as the building moves, creating vulnerabilities for water ingress.

- UV and Weather Resistance: Many types of expanding foam tape are designed to withstand exposure to UV rays and extreme weather. This resistance prevents degradation and preserves the integrity of the seal, ensuring that it remains effective against water ingress even in exposed locations like window sills, rooflines, and around exterior insulation panels.

Creates a seal

- Continuous Airtight Seal: Expanding foam tape expands to create a continuous, airtight seal around joints, insulation board edges, and between various EWI components. This prevents air leaks, which are a primary cause of heat loss and condensation within the building envelope. Without this airtight seal, an EWI system can suffer from drafts, cold spots, and reduced insulation effectiveness.

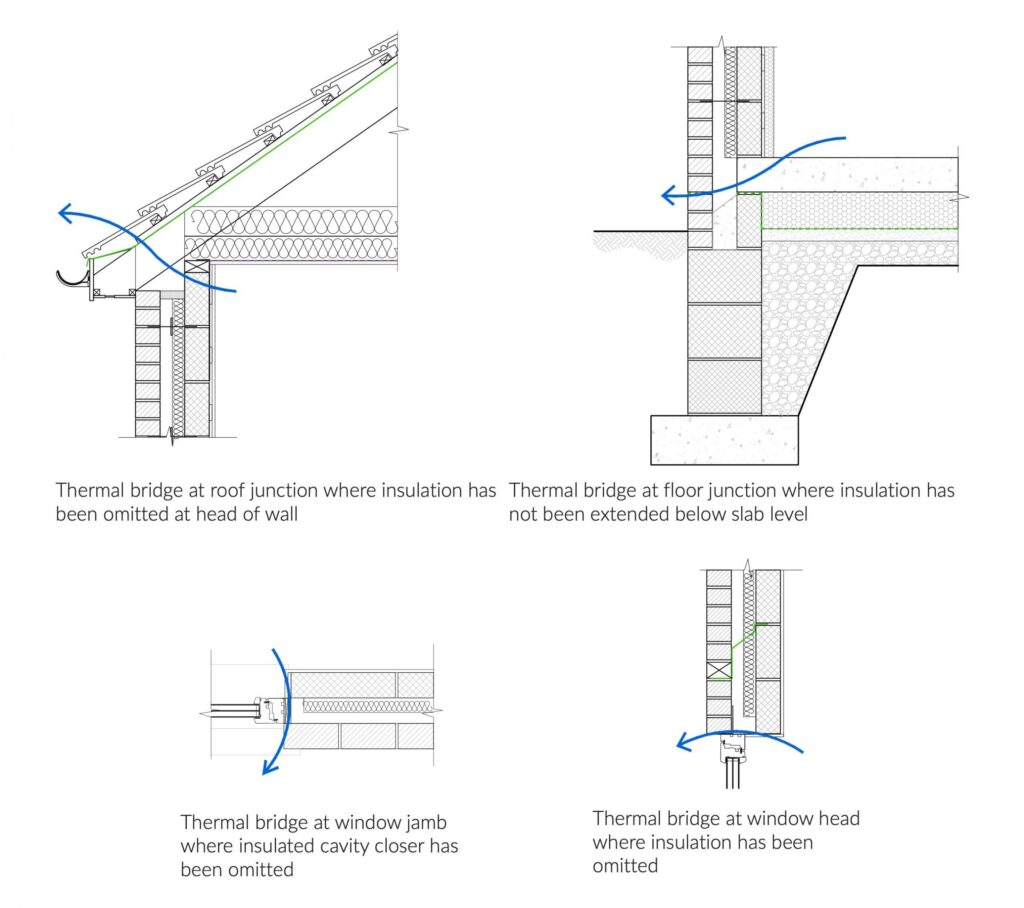

- Protection Against Thermal Bridging: Thermal bridging occurs when gaps or areas of poorly insulated material allow heat to escape. By sealing all joints and potential gaps between insulation boards, expanding foam tape blocks these thermal bridges, maintaining the insulation’s uniform performance and preventing cold spots on interior walls. This consistent thermal barrier is essential for optimising the insulation’s energy efficiency and lowering heating costs.

- Barrier Against Pollutants and Moisture: The airtight seal created by expanding foam tape protects against external pollutants, moisture, and dust. By keeping these elements out, the tape prevents issues like condensation build-up and mould, which can degrade the EWI system and lead to indoor air quality problems. This protective seal keeps the system and the internal environment healthier over time.

- Stability for Structural Components: The seal created by expanding foam tape helps stabilise the components within the EWI system, securing insulation boards and preventing movement due to wind or vibrations. This stability is especially important for high-rise buildings or areas exposed to extreme weather, as it prevents wear on system components.

- Support for Expansion and Contraction: Buildings naturally expand and contract due to temperature changes and environmental conditions. Expanding foam tape is uniquely suited to accommodate this movement without losing its seal. While rigid sealants like silicone may crack under these conditions, foam tape remains flexible, preserving the system’s integrity over decades. This adaptability ensures that the EWI system stays sealed without developing gaps or weaknesses over time.

Prevents thermal bridging

- Seals Joints and Gaps Between Insulation Boards: In EWI systems, insulation boards must be fitted tightly to form a consistent thermal layer. However, small gaps may still appear between boards even with precise installation. Expanding foam tape fills these gaps completely, expanding to conform to the edges of each board. This prevents heat from bypassing the insulation through these small spaces, blocking any potential path for thermal bridging.

- Creates an Unbroken Thermal Layer: Thermal bridging often occurs where different materials meet or break in the insulation layer, such as around windows, doors, and other penetrations. Expanding foam tape bridges these transition points, creating a continuous layer across the building envelope. By removing potential breaks in the thermal barrier, foam tape ensures that heat loss is kept to an absolute minimum.

- Maintains Insulation Performance in High-Risk Areas: Due to construction details, certain areas, like window frames, roofline junctions, and the damp-proof course (DPC) area, are particularly prone to thermal bridging. Expanding foam tape fills and seals these areas, adapting to surface irregularities. This reduces the likelihood of cold spots forming near these junctions, improving the comfort and thermal performance inside the building.

- Reduces Internal Condensation and Mould Growth: Cold spots caused by thermal bridging can lead to condensation inside the building as warm, moist indoor air meets cooler surfaces. Over time, this condensation can contribute to mould growth, affecting air quality and building integrity. By preventing thermal bridges, expanding foam tape reduces cold spots, lowers the risk of condensation, and helps maintain a dry, healthy interior.

- Enhances Thermal Performance Year-Round: Expanding foam tape keeps warm air inside the building in winter, reducing heating requirements and maintaining comfortable indoor temperatures. In summer, it helps keep cool air inside, improving the efficiency of air conditioning.

Allows for building movement

- Flexible Structure: Expanding foam tape is made from a highly compressible and elastic material, such as polyurethane foam, which can stretch and contract without losing its sealing effectiveness. This flexibility allows it to adjust to small shifts in the building structure, preserving the seal across critical joints and interfaces within the EWI system. The tape acts like a buffer that absorbs movement without tearing or cracking.

- Expands and Contracts with Temperature Changes: Buildings expand in warm weather and contract when temperatures drop, which can lead to subtle but consistent shifts in building materials. Expanding foam tape is designed to handle this thermal expansion and contraction by maintaining a constant pressure within the joint. As it is applied in a compressed state, it can contract when temperatures rise and expand to fill gaps as temperatures drop, keeping the seal intact throughout seasonal cycles.

- Effective in High-Movement Areas: Expanding foam tape is highly effective in these high-movement areas because it conforms tightly to surfaces, even when materials shift. It prevents gaps that could otherwise form with rigid sealants, reducing the risk of water ingress, thermal bridging, and air leakage.

- Adaptable to Wind and Vibrational Loads: Wind loads can create pressure on a building’s exterior, especially in tall structures or in regions exposed to high winds. Expanding foam tape has a resilient structure that absorbs and dissipates vibrational energy, meaning it won’t crack or detach under minor shifts caused by wind.

- Preventing Cracks and Damage in the EWI System: Rigid sealants can crack or debond over time as the building moves, leading to water ingress, thermal bridging, and energy loss. Expanding foam tape, on the other hand, is designed to maintain its position and seal despite movement, preventing the formation of cracks that can compromise the EWI system’s integrity.

Where should you use Expanding Foam Tape?

The easiest answer to this question is…EVERYWHERE! Expanding foam tape is essential and should be abundant throughout an EWI system. The point of an external wall insulation system is to create a sealed barrier around the whole property. Any small gaps will compromise that. Therefore, those gaps should be filled with expanding foam tape when applicable.

- Roofline Closure Systems: To create a weatherproof seal between the EWI system and the roofline, ensuring water doesn’t penetrate the system.

- Between the DPC and Insulation: Expanding foam tape seals the junction between the damp-proof course (DPC) and the insulation, preventing moisture from rising into the system and compromising insulation performance.

- Around Window Head Beads and Stop Beads: Foam tape can fill gaps around window head beads and stop beads, helping to seal and stabilise the system, especially as these areas are prone to slight movement over time.

- Around Weep Vents in Window Sills (Especially with Extended Oversills): Adding expanding foam tape here is essential, especially when oversills are used to extend existing window sills, as it prevents water ingress through these critical points.

- Between Insulation Boards in Certain Instances: In situations where insulation boards do not fit perfectly, expanding foam tape can fill gaps, minimising the risk of thermal bridging and air leakage.

How do you install it?

- Full Compression: The tape needs to be fully compressed to create an effective seal. This ensures that no air or moisture can pass through. A practical test for full compression is to try and blow through the tape; if air passes, it needs further compression.

- Positioning the Tape: Place the tape carefully, ensuring it fully covers the gap you’re sealing. Take care to align it with the surfaces you’re joining, whether around a bead, sill, or between insulation boards.

- Avoid Overlapping: Ensure the foam tape is cut to fit each area precisely, avoiding overlaps. Overlapping can create gaps and reduce the tape’s effectiveness.

- Check for Expansion and Coverage: After installation, allow the tape time to expand to its full potential, filling any uneven areas or gaps that may be present in the substrate or insulation boards.

Why is Expanding Foam Tape a better solution than silicone sealants?

Although silicone is commonly used as a sealant, it isn’t the most durable option in an EWI system. Over 5 to 10 years, silicone can degrade, becoming brittle and losing its sealing capabilities. This degradation exposes the system to water ingress and potential thermal inefficiencies.

In contrast, expanding foam tape and beading have a design life of 30 years, offering a more sustainable and cost-effective solution in the long run. Foam tape can withstand the building’s natural expansion and contraction without breaking down or detaching from surfaces. Paired with oversills and beading, it offers superior protection against the elements compared to silicone, ensuring the system remains sealed and effective for decades.

Facebook

Twitter

LinkedIn

Your cart

Trade Account Login

We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. By clicking “Accept All”, you consent to the use of ALL the cookies. However, you may visit "Cookie Settings" to provide personalised consent.

Manage consent

Privacy Overview

This website uses cookies to improve your experience while you navigate through the website. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. We also use third-party cookies that help us analyze and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may affect your browsing experience.

Necessary cookies are absolutely essential for the website to function properly. These cookies ensure basic functionalities and security features of the website, anonymously.

| Cookie | Duration | Description |

|---|---|---|

| __stripe_mid | 1 year | This cookie is set by Stripe payment gateway. This cookie is used to enable payment on the website without storing any patment information on a server. |

| __stripe_sid | 30 minutes | This cookie is set by Stripe payment gateway. This cookie is used to enable payment on the website without storing any patment information on a server. |

| _GRECAPTCHA | 5 months 27 days | This cookie is set by the Google recaptcha service to identify bots to protect the website against malicious spam attacks. |

| apbct_cookies_test | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_page_hits | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_prev_referer | session | Functional cookie placed by CleanTalk Spam Protect to store referring IDs and prevent unauthorized spam from being sent from the website. |

| apbct_site_landing_ts | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_site_referer | 3 days | This cookie is placed by CleanTalk Spam Protect to prevent spam and to store the referrer page address which led the user to the website. |

| apbct_timestamp | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_urls | 3 days | This cookie is placed by CleanTalk Spam Protect to prevent spam and to store the addresses (urls) visited on the website. |

| AWSALBCORS | 7 days | This cookie is managed by Amazon Web Services and is used for load balancing. |

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| ct_checkjs | session | CleanTalk–Used to prevent spam on our comments and forms and acts as a complete anti-spam solution and firewall for this site. |

| ct_fkp_timestamp | session | CleanTalk sets this cookie to prevent spam on the site's comments/forms, and to act as a complete anti-spam solution and firewall for the site. |

| ct_pointer_data | session | CleanTalk sets this cookie to prevent spam on the site's comments/forms, and to act as a complete anti-spam solution and firewall for the site. |

| ct_ps_timestamp | session | CleanTalk sets this cookie to prevent spam on the site's comments/forms, and to act as a complete anti-spam solution and firewall for the site. |

| ct_sfw_pass_key | 1 month | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| ct_timezone | session | CleanTalk–Used to prevent spam on our comments and forms and acts as a complete anti-spam solution and firewall for this site. |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features.

| Cookie | Duration | Description |

|---|---|---|

| __zlcmid | 1 year | This cookie is used by Zendesk live chat and is used to store the live chat ID. |

| bcookie | 2 years | LinkedIn sets this cookie from LinkedIn share buttons and ad tags to recognize browser ID. |

| bscookie | 2 years | LinkedIn sets this cookie to store performed actions on the website. |

| lang | session | LinkedIn sets this cookie to remember a user's language setting. |

| lidc | 1 day | LinkedIn sets the lidc cookie to facilitate data center selection. |

| UserMatchHistory | 1 month | LinkedIn sets this cookie for LinkedIn Ads ID syncing. |

Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.

| Cookie | Duration | Description |

|---|---|---|

| __utma | 2 years | This cookie is set by Google Analytics and is used to distinguish users and sessions. The cookie is created when the JavaScript library executes and there are no existing __utma cookies. The cookie is updated every time data is sent to Google Analytics. |

| __utmb | 30 minutes | Google Analytics sets this cookie, to determine new sessions/visits. __utmb cookie is created when the JavaScript library executes and there are no existing __utma cookies. It is updated every time data is sent to Google Analytics. |

| __utmc | session | The cookie is set by Google Analytics and is deleted when the user closes the browser. It is used to enable interoperability with urchin.js, which is an older version of Google Analytics and is used in conjunction with the __utmb cookie to determine new sessions/visits. |

| __utmt | 10 minutes | Google Analytics sets this cookie to inhibit request rate. |

| __utmv | 2 years | The __utmv cookie is set on the user's device, to enable Google Analytics to classify the visitor. |

| __utmz | 6 months | Google Analytics sets this cookie to store the traffic source or campaign by which the visitor reached the site. |

| sib_cuid | 6 months | Purechat uses this cookie to send data to purechat.com, to connect visitors to the reservation team and track visitors to stay on portal. |

| SRM_B | 1 year 24 days | Used by Microsoft Advertising as a unique ID for visitors. |

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc.

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _gat_gtag_UA_61069204_2 | 1 minute | Set by Google to distinguish users. |

| _gat_UA-61069204-2 | 1 minute | A variation of the _gat cookie set by Google Analytics and Google Tag Manager to allow website owners to track visitor behaviour and measure site performance. The pattern element in the name contains the unique identity number of the account or website it relates to. |

| _gcl_au | 3 months | Provided by Google Tag Manager to experiment advertisement efficiency of websites using their services. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| _uetsid | 1 day | This cookies are used to collect analytical information about how visitors use the website. This information is used to compile report and improve site. |

| CONSENT | 2 years | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. These cookies track visitors across websites and collect information to provide customized ads.

| Cookie | Duration | Description |

|---|---|---|

| _fbp | 3 months | This cookie is set by Facebook to display advertisements when either on Facebook or on a digital platform powered by Facebook advertising, after visiting the website. |

| ANONCHK | 10 minutes | The ANONCHK cookie, set by Bing, is used to store a user's session ID and also verify the clicks from ads on the Bing search engine. The cookie helps in reporting and personalization as well. |

| fr | 3 months | Facebook sets this cookie to show relevant advertisements to users by tracking user behaviour across the web, on sites that have Facebook pixel or Facebook social plugin. |

| MUID | 1 year 24 days | Bing sets this cookie to recognize unique web browsers visiting Microsoft sites. This cookie is used for advertising, site analytics, and other operations. |

| NID | 6 months | NID cookie, set by Google, is used for advertising purposes; to limit the number of times the user sees an ad, to mute unwanted ads, and to measure the effectiveness of ads. |

| test_cookie | 15 minutes | The test_cookie is set by doubleclick.net and is used to determine if the user's browser supports cookies. |

| uuid | 6 months | MediaMath sets this cookie to avoid the same ads from being shown repeatedly and for relevant advertising. |

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt-remote-device-id | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt.innertube::nextId | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |

| yt.innertube::requests | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |

Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet.

| Cookie | Duration | Description |

|---|---|---|

| _clck | 1 year | No description |

| _clsk | 1 day | No description |

| _uetvid | 1 year 24 days | No description available. |

| AnalyticsSyncHistory | 1 month | No description |

| apbct_pixel_url | session | No description |

| apbct_visible_fields_0 | session | No description |

| apbct_visible_fields_1 | session | No description |

| apbct_visible_fields_10 | session | No description |

| apbct_visible_fields_2 | session | No description |

| apbct_visible_fields_3 | session | No description |

| apbct_visible_fields_4 | session | No description |

| apbct_visible_fields_5 | session | No description |

| apbct_visible_fields_6 | session | No description |

| apbct_visible_fields_7 | session | No description |

| apbct_visible_fields_8 | session | No description |

| apbct_visible_fields_9 | session | No description |

| ct_checked_emails | session | No description |

| ct_has_scrolled | session | No description |

| ct_mouse_moved | session | No description |

| ct_screen_info | session | No description |

| ictf_master | never | No description available. |

| li_gc | 2 years | No description |

| m | 2 years | No description available. |

| SM | session | No description available. |

| testinfinitycookie | session | No description |

| woocommerce_show_tax | 7 days | No description available. |

| wp_woocommerce_session_c5ac76b408021294cb56bcc27eddf8a1 | 2 days | No description |