What is a Parge Coat?

When it comes to home improvement and masonry, you might have encountered the term “parge coat.” Despite its somewhat obscure name, a parge coat plays a vital role in protecting and enhancing the aesthetic appeal of various structures.

What is a parge coat?

A parge coat is a thin layer of mortar applied over a masonry surface. This coating is typically used on block or concrete walls to provide a smooth, uniform finish. The term “parging” refers to applying this mortar coat. Parging serves several purposes, including improving the wall’s appearance, providing additional protection against weather elements, and covering imperfections in the masonry work.

A typical parge coat is made from cement, sand, and water. Sometimes, additives are included to enhance the properties of the mortar, such as increasing its water resistance or improving its adhesion to the surface. The consistency of the mix is crucial; it should be thick enough to adhere to vertical surfaces without sagging but pliable enough to spread easily.

Applications

Parge coats are commonly used in various scenarios, including:

- Basement walls: One of the most common applications is on basement walls. Parging can help seal the porous concrete blocks, reducing moisture penetration and preventing minor leaks. This can be especially important in older homes where the basement walls might be more prone to moisture issues.

- Exterior walls: A parge coat can enhance the appearance of exterior walls, especially those made of concrete blocks, by providing a smooth, finished look. It can also serve as a base for painting or other decorative finishes, allowing for greater versatility in home design.

- Foundation walls: Parging is often used on the above-ground portion of foundation walls to protect against weather damage and improve aesthetics. It can help shield the foundation from rain, snow, and ice, which can cause wear and deterioration over time.

- Repair work: Parging can effectively repair minor cracks and surface damage on masonry walls, restoring both structural integrity and appearance. It’s a practical solution for rejuvenating older buildings without requiring extensive renovation.

Benefits of parge coats

Using a parge coat offers several benefits:

- Enhanced appearance: A smooth, uniform finish improves the visual appeal of otherwise rough or unattractive masonry surfaces, significantly boosting a property’s curb appeal.

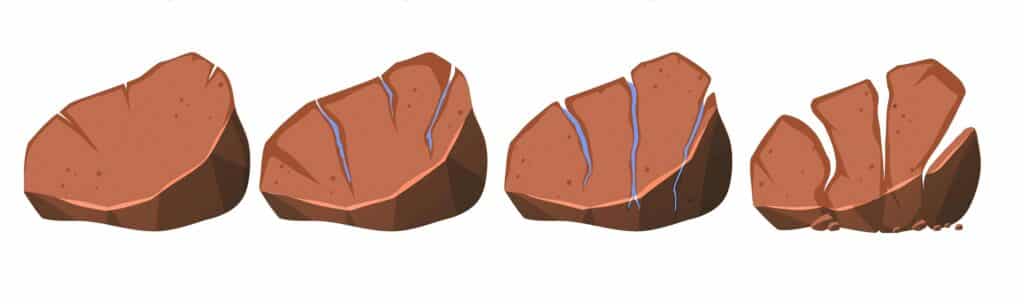

- Protection against elements: Parging provides an extra layer of protection against moisture, reducing the risk of water damage and improving the wall’s longevity. It also helps prevent the freeze-thaw cycle that can cause masonry to crack and deteriorate.

- Improved insulation: By sealing gaps and cracks, a parge coat can contribute to better insulation, helping to keep your home warmer in the winter and cooler in the summer. This can lead to energy savings and increased comfort. Whilst any improvement in the thermal mass and insulating capabilities of walls is crucial, a parge coat cannot match the performance of external wall insulation.

- Cost-effective: Parging is relatively inexpensive and straightforward compared to other methods of finishing or repairing masonry surfaces. It’s a cost-effective way to maintain and improve the value of your property.

- Acoustic performance: Fewer sound waves travel through the walls directly, leading to less noise.

How to apply a parge coat

Applying a parge coat involves several steps, and while it can be a DIY project, it’s often best handled by professionals to ensure a durable and even finish. Here’s a detailed overview of the process:

- Surface preparation: The masonry surface must be clean and free of loose debris, dust, and grease. Any significant cracks or holes should be filled beforehand. A thorough cleaning ensures that the mortar adheres properly to the surface.

- Mixing the mortar: A suitable sand, cement, and water mix is prepared. The consistency should be thick but workable. Additives can be included to improve the mortar’s properties, such as bonding agents for better adhesion or waterproofing agents for increased resistance to moisture. Depending on the type of material chosen, it may be sprayed onto the wall. Many spray machines have hopper attachments which mix your dry material with water to produce a homogeneous mixture.

- Application: The mortar is applied to the wall in a thin, even layer, typically about 1/4 inch thick, using a trowel. Working the mortar into the surface is important to ensure good adhesion. Sometimes, a metal lath may be installed over the surface to provide additional grip for the mortar.

- Smoothing: The surface is then smoothed out using a float or a trowel to achieve the desired finish. Different techniques can create various textures, from a smooth finish to a more rustic, textured look.

- Curing: After application, the parge coat needs to cure properly. This involves keeping it moist for several days to prevent cracking and ensure it sets correctly. Proper curing is essential to achieve a strong, durable finish.

“Greedy” Hopper Extension For MixPro 28

£630.00 Incl. VAT£525.00 Excl. VAT

Common questions

1. How long does a parge coat last? A well-applied parge coat can last many years, often up to 30 years or more, especially if maintained properly. Regular inspections and prompt repairs can extend its lifespan.

2. Can I paint over a parge coat? Yes, once it has fully cured, you can paint over it. Painting can provide additional protection and allow customisation to match your home’s aesthetic. As a parge coat is often painted, the initial application does not need to be perfectly smooth. However, it is crucial to apply a breathable topcoat like a Silicone Render or Silicone Paint. As the parge coat is applied to porous surfaces like bricks and is designed to breathe, the topcoat cannot trap moisture behind it.

3. What is the difference between parging and stucco? While both are mortar-based coatings, stucco typically involves multiple layers and is often used as a decorative finish. Parging is usually a thin coat applied primarily for protection and aesthetic improvement.

4. Can parging fix structural issues? Parging is not a solution for significant structural problems. It can cover minor cracks and surface damage, but major structural issues require professional assessment and appropriate repairs. The decision to apply a parge coat or seek further help depends on the depth. For example, EWI-260 Levelling Mortar can smooth surfaces up to a maximum thickness of 50mm.

Levelling Mortar (EWI-260) – 25kg

Rated 4.67 out of 5

£13.80 Incl. VAT£11.50 Excl. VAT£14.57 Incl. VAT£12.14 Excl. VAT

Facebook

Twitter

LinkedIn

Your cart

Trade Account Login

We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. By clicking “Accept All”, you consent to the use of ALL the cookies. However, you may visit "Cookie Settings" to provide personalised consent.

Manage consent

Privacy Overview

This website uses cookies to improve your experience while you navigate through the website. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. We also use third-party cookies that help us analyze and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may affect your browsing experience.

Necessary cookies are absolutely essential for the website to function properly. These cookies ensure basic functionalities and security features of the website, anonymously.

| Cookie | Duration | Description |

|---|---|---|

| __stripe_mid | 1 year | This cookie is set by Stripe payment gateway. This cookie is used to enable payment on the website without storing any patment information on a server. |

| __stripe_sid | 30 minutes | This cookie is set by Stripe payment gateway. This cookie is used to enable payment on the website without storing any patment information on a server. |

| _GRECAPTCHA | 5 months 27 days | This cookie is set by the Google recaptcha service to identify bots to protect the website against malicious spam attacks. |

| apbct_cookies_test | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_page_hits | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_prev_referer | session | Functional cookie placed by CleanTalk Spam Protect to store referring IDs and prevent unauthorized spam from being sent from the website. |

| apbct_site_landing_ts | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_site_referer | 3 days | This cookie is placed by CleanTalk Spam Protect to prevent spam and to store the referrer page address which led the user to the website. |

| apbct_timestamp | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_urls | 3 days | This cookie is placed by CleanTalk Spam Protect to prevent spam and to store the addresses (urls) visited on the website. |

| AWSALBCORS | 7 days | This cookie is managed by Amazon Web Services and is used for load balancing. |

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| ct_checkjs | session | CleanTalk–Used to prevent spam on our comments and forms and acts as a complete anti-spam solution and firewall for this site. |

| ct_fkp_timestamp | session | CleanTalk sets this cookie to prevent spam on the site's comments/forms, and to act as a complete anti-spam solution and firewall for the site. |

| ct_pointer_data | session | CleanTalk sets this cookie to prevent spam on the site's comments/forms, and to act as a complete anti-spam solution and firewall for the site. |

| ct_ps_timestamp | session | CleanTalk sets this cookie to prevent spam on the site's comments/forms, and to act as a complete anti-spam solution and firewall for the site. |

| ct_sfw_pass_key | 1 month | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| ct_timezone | session | CleanTalk–Used to prevent spam on our comments and forms and acts as a complete anti-spam solution and firewall for this site. |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features.

| Cookie | Duration | Description |

|---|---|---|

| __zlcmid | 1 year | This cookie is used by Zendesk live chat and is used to store the live chat ID. |

| bcookie | 2 years | LinkedIn sets this cookie from LinkedIn share buttons and ad tags to recognize browser ID. |

| bscookie | 2 years | LinkedIn sets this cookie to store performed actions on the website. |

| lang | session | LinkedIn sets this cookie to remember a user's language setting. |

| lidc | 1 day | LinkedIn sets the lidc cookie to facilitate data center selection. |

| UserMatchHistory | 1 month | LinkedIn sets this cookie for LinkedIn Ads ID syncing. |

Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.

| Cookie | Duration | Description |

|---|---|---|

| __utma | 2 years | This cookie is set by Google Analytics and is used to distinguish users and sessions. The cookie is created when the JavaScript library executes and there are no existing __utma cookies. The cookie is updated every time data is sent to Google Analytics. |

| __utmb | 30 minutes | Google Analytics sets this cookie, to determine new sessions/visits. __utmb cookie is created when the JavaScript library executes and there are no existing __utma cookies. It is updated every time data is sent to Google Analytics. |

| __utmc | session | The cookie is set by Google Analytics and is deleted when the user closes the browser. It is used to enable interoperability with urchin.js, which is an older version of Google Analytics and is used in conjunction with the __utmb cookie to determine new sessions/visits. |

| __utmt | 10 minutes | Google Analytics sets this cookie to inhibit request rate. |

| __utmv | 2 years | The __utmv cookie is set on the user's device, to enable Google Analytics to classify the visitor. |

| __utmz | 6 months | Google Analytics sets this cookie to store the traffic source or campaign by which the visitor reached the site. |

| sib_cuid | 6 months | Purechat uses this cookie to send data to purechat.com, to connect visitors to the reservation team and track visitors to stay on portal. |

| SRM_B | 1 year 24 days | Used by Microsoft Advertising as a unique ID for visitors. |

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc.

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _gat_gtag_UA_61069204_2 | 1 minute | Set by Google to distinguish users. |

| _gat_UA-61069204-2 | 1 minute | A variation of the _gat cookie set by Google Analytics and Google Tag Manager to allow website owners to track visitor behaviour and measure site performance. The pattern element in the name contains the unique identity number of the account or website it relates to. |

| _gcl_au | 3 months | Provided by Google Tag Manager to experiment advertisement efficiency of websites using their services. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| _uetsid | 1 day | This cookies are used to collect analytical information about how visitors use the website. This information is used to compile report and improve site. |

| CONSENT | 2 years | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. These cookies track visitors across websites and collect information to provide customized ads.

| Cookie | Duration | Description |

|---|---|---|

| _fbp | 3 months | This cookie is set by Facebook to display advertisements when either on Facebook or on a digital platform powered by Facebook advertising, after visiting the website. |

| ANONCHK | 10 minutes | The ANONCHK cookie, set by Bing, is used to store a user's session ID and also verify the clicks from ads on the Bing search engine. The cookie helps in reporting and personalization as well. |

| fr | 3 months | Facebook sets this cookie to show relevant advertisements to users by tracking user behaviour across the web, on sites that have Facebook pixel or Facebook social plugin. |

| MUID | 1 year 24 days | Bing sets this cookie to recognize unique web browsers visiting Microsoft sites. This cookie is used for advertising, site analytics, and other operations. |

| NID | 6 months | NID cookie, set by Google, is used for advertising purposes; to limit the number of times the user sees an ad, to mute unwanted ads, and to measure the effectiveness of ads. |

| test_cookie | 15 minutes | The test_cookie is set by doubleclick.net and is used to determine if the user's browser supports cookies. |

| uuid | 6 months | MediaMath sets this cookie to avoid the same ads from being shown repeatedly and for relevant advertising. |

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt-remote-device-id | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt.innertube::nextId | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |

| yt.innertube::requests | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |

Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet.

| Cookie | Duration | Description |

|---|---|---|

| _clck | 1 year | No description |

| _clsk | 1 day | No description |

| _uetvid | 1 year 24 days | No description available. |

| AnalyticsSyncHistory | 1 month | No description |

| apbct_pixel_url | session | No description |

| apbct_visible_fields_0 | session | No description |

| apbct_visible_fields_1 | session | No description |

| apbct_visible_fields_10 | session | No description |

| apbct_visible_fields_2 | session | No description |

| apbct_visible_fields_3 | session | No description |

| apbct_visible_fields_4 | session | No description |

| apbct_visible_fields_5 | session | No description |

| apbct_visible_fields_6 | session | No description |

| apbct_visible_fields_7 | session | No description |

| apbct_visible_fields_8 | session | No description |

| apbct_visible_fields_9 | session | No description |

| ct_checked_emails | session | No description |

| ct_has_scrolled | session | No description |

| ct_mouse_moved | session | No description |

| ct_screen_info | session | No description |

| ictf_master | never | No description available. |

| li_gc | 2 years | No description |

| m | 2 years | No description available. |

| SM | session | No description available. |

| testinfinitycookie | session | No description |

| woocommerce_show_tax | 7 days | No description available. |

| wp_woocommerce_session_c5ac76b408021294cb56bcc27eddf8a1 | 2 days | No description |