Drying, setting, and curing are terms often heard in the building industry. However, they do mean different things. Their meaning is intrinsically linked to cement as many products used in the building industry are cementitious. We will often mention drying, setting, and curing times on our product pages and technical documents, therefore this blog will hopefully serve as a reference point for any questions regarding those terms.

What is drying time?

Drying refers to the evaporation of water from a cementitious material after mixing. As the water evaporates, the material loses moisture and shrinks. Drying time is influenced by factors such as the water-to-cement ratio, ambient temperature, relative humidity, and the type of cementitious material used. It is essential to consider in construction, as excessive shrinkage can lead to cracking and reduced strength.

Drying time is critical for the dimensional stability of cementitious materials. During the drying process, capillary pressure develops as water evaporates, causing the material to shrink. The process is called plastic shrinkage and occurs due to the pore system in the material. Loss of water during the initial evaporations stage leads to the formation of menisci. As the radius of the menisci shrinks, the capillary water pressure rises, causing instability. As a result, some air is allowed to penetrate the system. Excessive shrinkage can lead to cracking, compromised bond strength, and reduced durability. Some key factors affecting drying time include:

- Water-to-cement ratio: Higher water content in the mix leads to increased drying time, as more water needs to evaporate.

- Aggregate type and size: The type and size of aggregates can affect the drying time due to their ability to retain or release moisture.

- Ambient temperature and humidity: High temperatures and low humidity can accelerate the drying process, while low temperatures and high humidity can slow it down.

- Air movement and ventilation: Good air circulation can help accelerate the drying process by promoting evaporation. This can be further supplemented by introducing dehumidifiers or other means of active ventilation.

What is 'setting' time?

'Setting' is the process during which the cementitious material transitions from a plastic, workable state to a rigid, solid state. It involves the initial hydration of cement particles, which form a gel-like structure that binds the aggregates together. Setting time is influenced by factors such as the type of cement, the presence of admixtures, temperature, and the water-to-cement ratio. Proper setting time is crucial to ensure adequate strength development and prevent deformation during the early stages of construction.

Setting time is typically divided into two stages; initial setting time and final setting time. Initial setting time is the time required for the cementitious material to reach a certain level of rigidity. After this, it can no longer be easily manipulated or worked. Final setting time is a step further as it concerns itself with a level of rigidity that can sustain a certain level of load or stress. The cementitious product becomes load-bearing at this stage. The setting stage is particularly crucial to consider when working with self-levelling compounds; they will invariably be load-bearing, therefore require proper setting. EWI Store's Self-Levelling Compound sets in 24 hours.

Setting time is crucial for the workability and early-age strength development of cementitious materials:

- Cement type: For example, rapid-hardening cement sets more quickly than ordinary Portland cement (OPC).

- Admixtures: Accelerators and retarders, can modify the setting time of cementitious materials. Accelerators speed up the setting time, while retarders slow it down.

- Temperature: Higher temperatures can accelerate the setting process, while lower temperatures slow it down. Cold weather may require the use of accelerators to maintain proper setting times.

- Water-to-cement ratio: A higher water-to-cement ratio can increase the setting time due to the increased amount of water that needs to react with the cement particles.

What is curing time?

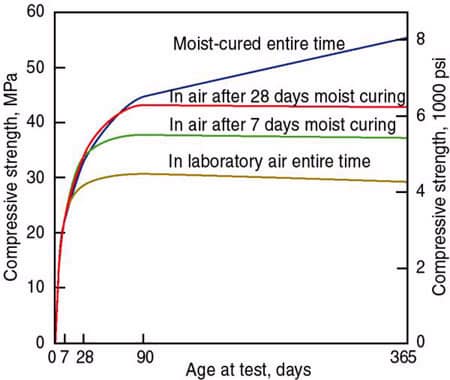

Curing is the process of maintaining optimal temperature and moisture conditions to allow the cementitious material to achieve its desired strength and durability. This process involves the continuation of cement hydration, which forms a strong and dense matrix. Curing time is typically measured in days or weeks. It varies depending on factors such as the type of cementitious material, the intended use of the structure, and environmental conditions.

Adequate curing time is essential to ensure that the cementitious material achieves its maximum potential strength and durability. If curing conditions are not maintained or if curing is stopped prematurely, the material may not reach its desired strength, leading to reduced performance and potential structural issues.

The curing process is affected by several factors; cement type, environmental conditions, mix proportions, and intended use and loading conditions. For instance, high early-strength cement requires shorter curing periods to reach the desired strength. Temperature and humidity play a significant role in the curing process. Hot and dry conditions may require more extended curing periods. Additional measures like wet curing or using curing compounds to prevent excessive moisture loss. Furthermore, the water-to-cement ratio and the use of supplementary cementitious materials impact curing time.

The load is something to consider before selecting your cementitious product. Heavily loaded structures or structures with high durability requirements may necessitate longer curing periods to ensure adequate strength development.

Curing methods

There are three methods of curing for cementitious products, all crucial to achieving the desired durability;

- Water curing - Continuously spraying water on the surface or submerging the cementitious material in water.

- Moist curing - Cover the surface with wet burlap, cotton mats, or plastic sheets to maintain moisture.

- Chemical curing - Applying a curing compound to the surface to slow down the evaporation of water.

Basecoat thickness

There are two schools of thought when it comes to applying basecoat; some will prefer a thin coat whilst others prefer a thicker coat. Some basecoats will require a thicker pass because they require time to cure. If they are applied too thin, the water is sucked into the brick and evaporates into the air. As a result, the basecoat dries but does not cure. This can lead to issues like cracking as the capillary pressure rises.

EWI Store products

EWI Store products are designed to dry within a reasonable period to allow for jobs to be completed quickly and efficiently. As a general rule of thumb, most will dry within 24 hours and as a result, are ready to be worked on further. However, some products are specially designed to dry more quickly. For example, Mineral Render dries within a couple of hours in the winter. This can be beneficial in various weather conditions, especially in colder weather.

Warm, sunny weather is always beneficial to accelerated drying time, but caution is advised. If products like silicone render dry too quickly in direct sunlight, they can be susceptible to cracking. We do offer products that make an impact on drying time; Render Accelerator is specially formulated to be used with Silicone and Acrylic renders to cut drying time in half.