What is the Fire Rating Scale for Insulation?

When it comes to building construction and safety, one of the most critical factors to consider is how materials respond to fire. Insulation, a major component used in buildings for temperature regulation, also plays a significant role in fire safety. Understanding the fire rating scale for insulation can help builders, architects, and homeowners make informed decisions to enhance safety and comply with building regulations. This blog explores the fire rating scale for insulation, discussing its importance, the different types of ratings, and how these affect building safety.

Why is a fire rating important?

Enhanced fire safety

A good fire rating for insulation enhances a building’s overall fire safety. Materials that are resistant to fire can help contain and slow the spread of flames, reducing the risk of fire moving from one part of a building to another. This containment is vital during a fire incident, providing occupants with more time to evacuate safely.

Reduced smoke production

Insulation materials that have a higher fire rating not only resist burning but also produce less smoke when exposed to fire. Smoke is one of the leading causes of harm in fire incidents, as it can obscure vision, hinder breathing, and contain toxic gases that can incapacitate individuals, preventing them from escaping. By using insulation with a low smoke production rating, the air quality is better preserved in the event of a fire, enhancing the chances of a safe evacuation.

Prevention of fire spread

Insulation is often used throughout buildings, running through walls, floors, and ceilings. Insulation that is not fire-resistant can act as a fuel source, significantly accelerating fire spread throughout the structure. Fire-rated insulation materials are designed to not only withstand heat but also to prevent the spread of fire. This is crucial in high-rise buildings, hospitals, schools, and other large structures where evacuating people safely can take more time.

Compliance with building codes

Building codes and regulations often mandate specific fire ratings for insulation based on the type of construction and its intended use. These regulations are designed to ensure that all buildings meet a minimum standard for fire safety, which is particularly important in densely populated areas or buildings with vulnerable populations. Using the correct fire-rated insulation is necessary to comply with these regulations and avoid legal repercussions.

Insurance requirements

Insurance companies may require that buildings use materials that meet specific fire safety standards, including fire-rated insulation, to reduce risks. Compliance with these requirements can affect insurance premiums, liability, and coverage scope, especially in commercial properties. In the event of a fire, having the correct fire-rated insulation can affect the outcome of insurance claims related to fire damage.

Long-term building integrity

Buildings that incorporate high-standard fire-rated insulation are more likely to maintain structural integrity in the event of a fire. This not only helps in potentially saving lives during the incident but also preserves the building’s framework, leading to potentially lower restoration costs post-fire.

The fire rating scale

The fire rating of insulation materials is generally determined through specific tests that measure flame spread and smoke-developed indices.

- The Flame Spread Index (FSI) measures how fast and far flames spread along the surface of the insulation during the first ten minutes of a test. The lower the FSI, the better the material resists fire spread.

- Smoke Developed Index (SDI) assesses the amount of smoke a material produces when it burns. Similar to the FSI, a lower SDI is preferable as it indicates less smoke production, which is vital for visibility and toxicity levels during a fire.

Categorising ratings

Class A (or Class 0 in the UK)

- Flame Spread Index (FSI): 0-25

- Smoke Developed Index (SDI): Less than or equal to 450

Class A or Class 0 materials have the highest resistance to fire. They are designed to be non-combustible, meaning they do not contribute significantly to a fire’s fuel load. These materials are ideal for use in areas where the risk of fire is higher, such as commercial kitchens, public theatres, or buildings with heavy electrical equipment. They are also often required in external cladding and roofing in both residential and commercial buildings.

Class B

- Flame Spread Index (FSI): 26-75

- Smoke Developed Index (SDI): Less than or equal to 450

Class B materials have a moderate resistance to fire. They are typically used in places with a lesser likelihood of severe fire exposure but where a good level of fire resistance is still necessary. This rating is common for interior walls and ceilings in residential and commercial buildings.

Class C

- Flame Spread Index (FSI): 76-200

- Smoke Developed Index (SDI): Less than or equal to 450

Class C insulation materials offer basic protection and are suitable for areas with a lower risk of fire exposure. They are often used in residential settings where regulations may not require higher-rated materials. This class is adequate for parts of buildings that are less likely to be sources or accelerators of a fire.

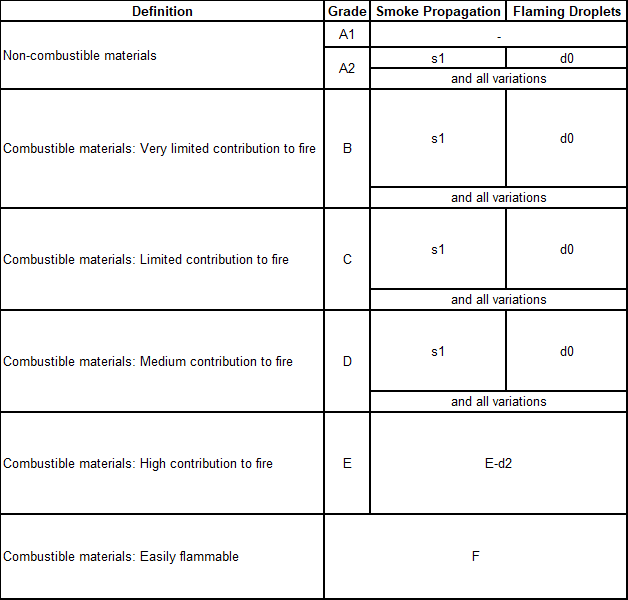

Class D, E, and F (European Standards)

- These classes indicate progressively lower degrees of fire resistance.

- Not commonly used in direct comparison to U.S. standards but important in European contexts.

These classes are less resistant to fire than Classes A, B, and C and are used less frequently in critical areas of construction. They may be suitable for applications where other fire prevention measures are in place or where the risk of fire is minimal.

How do different insulation materials measure up?

Mineral wool (including rock and glass wool) is naturally non-combustible and typically achieves a Class A fire rating. This makes it an excellent choice for fire safety as it does not contribute to the spread of flames or produce significant amounts of toxic smoke. Mineral wool can withstand temperatures up to about 1000°C, making it highly effective in preventing fire spread. The reason for mineral wool resisting fire so well is the composition. Most mineral wool products are produced from volcanic rock, which is naturally extremely temperature-resistant. The rock is melted into fibres and then spun into large batts that form the boards.

Source: Rockwool YouTube

EPS is a type of foam insulation that, in its basic form, is not highly fire-resistant. Standard EPS usually falls into Class E under European standards, indicating a higher flammability. However, fire-retardant grades of EPS are available that perform better and can reach Class B ratings. These are treated with fire-retardant substances to reduce flammability.

Kingspan K5 is an insulation board used primarily for external insulation systems. It is made of phenolic foam, which offers superior fire performance compared to many foam insulations. Under the UK building regulations, Kingspan K5 generally achieves a Class 0 rating, corresponding to a high level of fire resistance. It is classified as having low flame spread and low smoke production.

Wood fibre insulation generally has lower fire resistance than mineral wool or phenolic foams. Untreated wood fibre can be quite flammable; however, it is often treated with fire retardants to improve its fire resistance. Typically, treated wood fibre insulation can achieve Class E or Class D ratings, making it less suitable for high-risk areas unless additional protective measures are taken.

Facebook

Twitter

LinkedIn

Your cart

Trade Account Login

We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. By clicking “Accept All”, you consent to the use of ALL the cookies. However, you may visit "Cookie Settings" to provide personalised consent.

Manage consent

Privacy Overview

This website uses cookies to improve your experience while you navigate through the website. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. We also use third-party cookies that help us analyze and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may affect your browsing experience.

Necessary cookies are absolutely essential for the website to function properly. These cookies ensure basic functionalities and security features of the website, anonymously.

| Cookie | Duration | Description |

|---|---|---|

| __stripe_mid | 1 year | This cookie is set by Stripe payment gateway. This cookie is used to enable payment on the website without storing any patment information on a server. |

| __stripe_sid | 30 minutes | This cookie is set by Stripe payment gateway. This cookie is used to enable payment on the website without storing any patment information on a server. |

| _GRECAPTCHA | 5 months 27 days | This cookie is set by the Google recaptcha service to identify bots to protect the website against malicious spam attacks. |

| apbct_cookies_test | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_page_hits | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_prev_referer | session | Functional cookie placed by CleanTalk Spam Protect to store referring IDs and prevent unauthorized spam from being sent from the website. |

| apbct_site_landing_ts | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_site_referer | 3 days | This cookie is placed by CleanTalk Spam Protect to prevent spam and to store the referrer page address which led the user to the website. |

| apbct_timestamp | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_urls | 3 days | This cookie is placed by CleanTalk Spam Protect to prevent spam and to store the addresses (urls) visited on the website. |

| AWSALBCORS | 7 days | This cookie is managed by Amazon Web Services and is used for load balancing. |

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| ct_checkjs | session | CleanTalk–Used to prevent spam on our comments and forms and acts as a complete anti-spam solution and firewall for this site. |

| ct_fkp_timestamp | session | CleanTalk sets this cookie to prevent spam on the site's comments/forms, and to act as a complete anti-spam solution and firewall for the site. |

| ct_pointer_data | session | CleanTalk sets this cookie to prevent spam on the site's comments/forms, and to act as a complete anti-spam solution and firewall for the site. |

| ct_ps_timestamp | session | CleanTalk sets this cookie to prevent spam on the site's comments/forms, and to act as a complete anti-spam solution and firewall for the site. |

| ct_sfw_pass_key | 1 month | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| ct_timezone | session | CleanTalk–Used to prevent spam on our comments and forms and acts as a complete anti-spam solution and firewall for this site. |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features.

| Cookie | Duration | Description |

|---|---|---|

| __zlcmid | 1 year | This cookie is used by Zendesk live chat and is used to store the live chat ID. |

| bcookie | 2 years | LinkedIn sets this cookie from LinkedIn share buttons and ad tags to recognize browser ID. |

| bscookie | 2 years | LinkedIn sets this cookie to store performed actions on the website. |

| lang | session | LinkedIn sets this cookie to remember a user's language setting. |

| lidc | 1 day | LinkedIn sets the lidc cookie to facilitate data center selection. |

| UserMatchHistory | 1 month | LinkedIn sets this cookie for LinkedIn Ads ID syncing. |

Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.

| Cookie | Duration | Description |

|---|---|---|

| __utma | 2 years | This cookie is set by Google Analytics and is used to distinguish users and sessions. The cookie is created when the JavaScript library executes and there are no existing __utma cookies. The cookie is updated every time data is sent to Google Analytics. |

| __utmb | 30 minutes | Google Analytics sets this cookie, to determine new sessions/visits. __utmb cookie is created when the JavaScript library executes and there are no existing __utma cookies. It is updated every time data is sent to Google Analytics. |

| __utmc | session | The cookie is set by Google Analytics and is deleted when the user closes the browser. It is used to enable interoperability with urchin.js, which is an older version of Google Analytics and is used in conjunction with the __utmb cookie to determine new sessions/visits. |

| __utmt | 10 minutes | Google Analytics sets this cookie to inhibit request rate. |

| __utmv | 2 years | The __utmv cookie is set on the user's device, to enable Google Analytics to classify the visitor. |

| __utmz | 6 months | Google Analytics sets this cookie to store the traffic source or campaign by which the visitor reached the site. |

| sib_cuid | 6 months | Purechat uses this cookie to send data to purechat.com, to connect visitors to the reservation team and track visitors to stay on portal. |

| SRM_B | 1 year 24 days | Used by Microsoft Advertising as a unique ID for visitors. |

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc.

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _gat_gtag_UA_61069204_2 | 1 minute | Set by Google to distinguish users. |

| _gat_UA-61069204-2 | 1 minute | A variation of the _gat cookie set by Google Analytics and Google Tag Manager to allow website owners to track visitor behaviour and measure site performance. The pattern element in the name contains the unique identity number of the account or website it relates to. |

| _gcl_au | 3 months | Provided by Google Tag Manager to experiment advertisement efficiency of websites using their services. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| _uetsid | 1 day | This cookies are used to collect analytical information about how visitors use the website. This information is used to compile report and improve site. |

| CONSENT | 2 years | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. These cookies track visitors across websites and collect information to provide customized ads.

| Cookie | Duration | Description |

|---|---|---|

| _fbp | 3 months | This cookie is set by Facebook to display advertisements when either on Facebook or on a digital platform powered by Facebook advertising, after visiting the website. |

| ANONCHK | 10 minutes | The ANONCHK cookie, set by Bing, is used to store a user's session ID and also verify the clicks from ads on the Bing search engine. The cookie helps in reporting and personalization as well. |

| fr | 3 months | Facebook sets this cookie to show relevant advertisements to users by tracking user behaviour across the web, on sites that have Facebook pixel or Facebook social plugin. |

| MUID | 1 year 24 days | Bing sets this cookie to recognize unique web browsers visiting Microsoft sites. This cookie is used for advertising, site analytics, and other operations. |

| NID | 6 months | NID cookie, set by Google, is used for advertising purposes; to limit the number of times the user sees an ad, to mute unwanted ads, and to measure the effectiveness of ads. |

| test_cookie | 15 minutes | The test_cookie is set by doubleclick.net and is used to determine if the user's browser supports cookies. |

| uuid | 6 months | MediaMath sets this cookie to avoid the same ads from being shown repeatedly and for relevant advertising. |

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt-remote-device-id | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt.innertube::nextId | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |

| yt.innertube::requests | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |

Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet.

| Cookie | Duration | Description |

|---|---|---|

| _clck | 1 year | No description |

| _clsk | 1 day | No description |

| _uetvid | 1 year 24 days | No description available. |

| AnalyticsSyncHistory | 1 month | No description |

| apbct_pixel_url | session | No description |

| apbct_visible_fields_0 | session | No description |

| apbct_visible_fields_1 | session | No description |

| apbct_visible_fields_10 | session | No description |

| apbct_visible_fields_2 | session | No description |

| apbct_visible_fields_3 | session | No description |

| apbct_visible_fields_4 | session | No description |

| apbct_visible_fields_5 | session | No description |

| apbct_visible_fields_6 | session | No description |

| apbct_visible_fields_7 | session | No description |

| apbct_visible_fields_8 | session | No description |

| apbct_visible_fields_9 | session | No description |

| ct_checked_emails | session | No description |

| ct_has_scrolled | session | No description |

| ct_mouse_moved | session | No description |

| ct_screen_info | session | No description |

| ictf_master | never | No description available. |

| li_gc | 2 years | No description |

| m | 2 years | No description available. |

| SM | session | No description available. |

| testinfinitycookie | session | No description |

| woocommerce_show_tax | 7 days | No description available. |

| wp_woocommerce_session_c5ac76b408021294cb56bcc27eddf8a1 | 2 days | No description |