Silicone Paint (EWI-005) – 5 Litres

From £42.21 Excl. VAT

- Internal & external use

- Hydrophobic

- Resistant to algae and plant growth

- Ideal for sealing Mineral Render systems

EWI-005 Silicone Paint

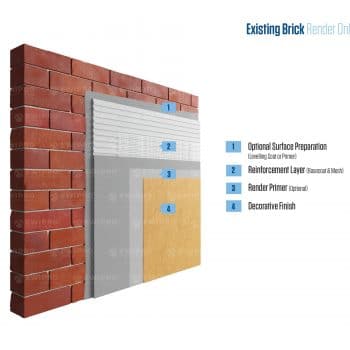

EWI-005 Silicone Paint is a high-performance masonry paint. This product is ideal for painting over an existing render as a way to refresh the facade and create a finish that looks brand new. It is also great for painting over our Mineral Render to seal the render in.

We suggest you apply the Silicone Paint 3-7 days after the Mineral Render has been applied to the substrate. However, this depends on weather conditions. This will ensure that a strong physical and chemical bond forms between the Mineral Render and the masonry paint.

Preparation

Before application, the surface of the substrate must be clean and dry. You should be sure to adequately protect any surfaces that you don’t intend to paint. Check that the paint is the requested colour. Mix Silicone Paint thoroughly within its container to ensure an even distribution of colour pigments. If using more than one tin of paint for the same surface, you should ensure that you match the batch numbers.

Application

Apply the masonry paint using brushes, rollers or spray equipment. Best practice when using a silicone-based paint is to apply the paint to the substrate in a continuous manner one wall/surface at a time. This will ensure that there are no visible drying lines where sections of paint meet. When used as a topcoat to our Mineral Render system, the masonry paint should be applied 3-7 days after rendering and at the latest 21 days after rendering, depending on weather conditions. When painting over the top of multi-layer render coats, the last layer must be 7 days old.

Paints with intense colours (reflection coefficient Y < 20%) should not be used for large facades; the resulting temperature and UV radiation in these conditions may reduce the durability of paint coats and may cause colour fading.

EWI-005 Silicone Paint Application Conditions

- Application temperature (air, substrate, materials): from +5°C to +25°C

- Number of coats required: 1

- Drying time: approx. 12 hours at +20°C

- Quantity to be used for single coats: about 150-250 ml/m² (depending on the absorptive capacity, substrate structure and application method)

EWI-005 Silicone Paint Storage Conditions

Shelf life: up to 12 months from the date of manufacture. Keep dry and in the original packaging at a temperature of +5°C to +25°C.

Frequently Asked Questions

- What makes Silicone Paint different from standard paint?

Silicone Paint is different from standard paint as it contains silicone resins. Silicone Paint is hydrophobic, repelling water, keeping walls free from water damage and highly breathable, allowing moisture trapped behind to escape freely.

- Can I use Silicone Paint internally and externally?

Silicone Paint can be used both internally and externally.

- What colours can you choose from when buying Silicone Paint?

EWI Store offers 36 standard colours to choose from; however, our smart tinting machines can tint paint to thousands of colours.

- When can I paint over Mineral Render with Silicone Paint?

Depending on the weather conditions, Silicone Paint should be applied 3 to 7 days after the Mineral Render has been applied to the substrate.

- Can I use Silicone Render to paint over existing Silicone Render?

You can use Silicone Paint to paint over Silicone Render. We recommend using Silicone Paint over standard masonry paint as it is highly breathable and hydrophobic. Before painting over the render, ensure that the walls are clean of dirt and apply tape to any areas that need protection from the paint.

| Weight | 7 kg |

|---|---|

| Colour | Acorn, Almond, Antique White, Ash, Bone, Brilliant White, Clay, Cloud, Concrete, Copenhagen, Diamond, Eggshell, Elderflower, Fog, Frost, Haze, Ice, Ivory, Lead, Linen, Magnolia, Mirror, Mist, Opal, Orchid, Paraffin, Platinum, Porcelain, Prosecco, Pure White, Sage Green, Sandstone, Silk, Silver, Smoke, Storm, Truffle |

| Litre | |

| Brand | EWIPRO |

Reviews

There are no reviews yet.