How to Make Your Project More Eco-Friendly

As the building industry grows, it tends to progress with the times. As such, sustainable building practices come into the consciousness more and more. This includes making eco-friendly choices. These choices relate to the materials, from manufacturing to transport, and many other factors. As installers, you are a little more reliant on the supplier making a conscious effort to be more eco-friendly. However, several things can be done on-site to make the project more sustainable and eco-friendly.

What are sustainable building practices?

Sustainable building practices, also known as green building practices, aim to create structures that are environmentally responsible and resource-efficient throughout a building’s life cycle. This involves the planning, design, construction, operation, maintenance, renovation, and demolition of buildings.

- Energy efficiency: Sustainable buildings often include systems for using less energy. This might involve installing solar panels, wind turbines, or other renewable energy sources. It could also include the use of energy-efficient appliances and lighting, as well as designs that take advantage of natural light and heat.

- Water efficiency: Involves the use of low-flow faucets and toilets, rainwater harvesting systems, and greywater recycling.

- Material efficiency: This involves using sustainable, recyclable, or reused materials in the construction process. It could also involve practices that reduce waste during construction.

- Indoor environmental quality enhancement: Involves using paints and other materials that don’t emit volatile organic compounds (VOCs), ensuring good ventilation, and designing spaces that maximise natural light.

- Operations and maintenance optimisation: Ensuring that the building continues to operate efficiently and sustainably over the long term. This occurs through practices such as regular maintenance and upgrades, as well as monitoring of energy and water use.

- Site sustainability: This involves considerations about the building’s location, its impact on the local environment, and the use of landscaping to enhance energy efficiency and water conservation. It might also involve planning for public transportation access to reduce reliance on private vehicles.

- Waste reduction: Waste reduction strategies may be used in both the construction and operation of the building, including recycling programs and composting.

-

Wind turbines -

Mineral wool, an infinitely recyclable insulation -

Compost bins

To measure and encourage sustainable building, several rating systems have been developed around the world. In the UK, the Building Research Establishment Environmental Assessment Method (BREEAM) measures such practices.

Eco-friendly practices

Making an external wall insulation project more eco-friendly involves considering the lifecycle of materials, energy efficiency, and waste management.

Use Eco-friendly insulation materials

In the context of an eco-friendly insulation project, the choice of materials is paramount. Instead of traditional materials like fibreglass, one could use eco-friendly insulation options such as sheep’s wool, cellulose (which is often made from recycled newsprint), cork, and wood fibre. These materials not only have excellent insulating properties, but they are also renewable, biodegradable, and require less energy to produce compared to traditional insulation materials.

Even materials like EPS and Mineral Wool are recyclable. Mineral Wool is inherently natural and infinitely recyclable, however, manufacturers are making significant strides to ensure that EPS off-cuts are collected and recycled. Therefore, there is less wastage. Styrene in particular has invested heavily in EPS recycling:

“I’d like to get in something about the EPS before render being 100% recyclable meaning all offcuts from the site are returned and put back into other insulation materials. EPS is falsely frowned upon in some aspects due to people not being aware of these credentials and our investment in our recycling infrastructure.” (Simon Rogers, Styrene)

-

Rockwool External Wall Dual Density Slab

Rated 5.00 out of 5From £26.24 Incl. VATFrom £21.87 Excl. VAT -

EPS Insulation (1 board = 0.72m²)

Rated 5.00 out of 5From £141.9 Incl. VATFrom £2.39 Incl. VATFrom £1.99 Excl. VAT

Life cycle analysis

When choosing insulation materials, it’s important to consider the entire lifecycle of the product – from sourcing and manufacturing to installation, use, and end-of-life. This holistic approach, often referred to as Life Cycle Analysis(LCA), helps to gauge the total environmental impact of a material. For instance, if a product has a low impact during use but a high impact during production or disposal, it may not be the most eco-friendly choice. LCA enables you to select materials that minimise environmental harm at every stage of their lifecycle.

Use of local materials

Using locally sourced materials can substantially decrease the environmental footprint of your insulation project. Local materials eliminate the need for long-distance transportation, thereby reducing carbon emissions associated with the project. Additionally, using local materials can support the local economy and often ensures that materials are better suited to local climate conditions.

Proper installation

Even the most eco-friendly insulation material can underperform if not installed correctly. Proper installation ensures the insulation works effectively, reducing the energy required to heat or cool the building. This in turn lowers the building’s greenhouse gas emissions and reduces energy costs. Techniques such as ensuring air tightness, and taking care not to compress the insulation optimise its performance.

Waste management

Creating a waste management plan is a crucial part of any eco-friendly project. For an insulation project, this could mean recycling any offcuts or waste material produced during installation. The packaging of the insulation material also needs to be considered. Opting for materials with minimal or recyclable packaging can significantly reduce the amount of waste going to landfill.

Energy-efficient manufacturing processes

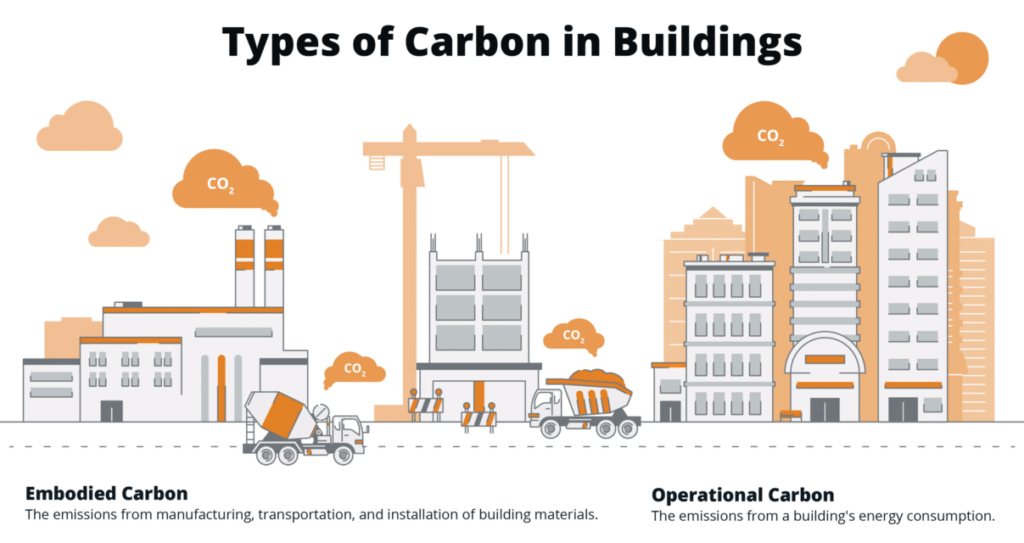

Selecting insulation materials that are manufactured using energy-efficient methods can also reduce the overall environmental impact of your project. Some manufacturers use renewable energy sources to power their production processes or have implemented measures to reduce their energy use. The carbon involved in manufacturing is split into embodied and operational carbon.

- Embodied carbon refers to the amount of carbon dioxide (CO2) and other greenhouse gases (GHGs) emitted during the manufacture, transport, and construction of building materials, together with end-of-life emissions. It is a one-time carbon footprint that occurs during the material’s production phase, hence the term ’embodied’. Selecting materials produced with energy-efficient methods or renewable energy helps reduce the embodied carbon of the material. For insulation materials, choosing options that have lower embodied carbon, such as those made from recycled or natural materials, is a key part of an eco-friendly approach.

- Operational carbon refers to the emissions that are generated during the use phase of a building, primarily from heating, cooling, and power usage. By using well-chosen insulation materials, the amount of energy required to maintain comfortable temperatures in a building can be significantly reduced. Therefore lowering the operational carbon. In an eco-friendly insulation project, both the embodied carbon of the insulation material itself and the operational carbon of the resulting building need to be considered. An insulation material might have a slightly higher embodied carbon. However, if it is significantly more effective at insulating the building, the overall reduction in operational carbon could result in a lower total carbon footprint over the building’s lifecycle.

Sustainable maintenance and repair

Sustainability should be considered not just during installation but also throughout the lifespan of the insulation. This could involve using eco-friendly materials when repairs are needed and implementing a maintenance schedule to ensure the insulation continues to perform optimally. Regular checks and proper maintenance can extend the life of the insulation, reducing the need for replacement materials.

Durability

The durability of an insulation material is another important factor to consider. Materials that are durable and long-lasting are often more eco-friendly because they need to be replaced less frequently. This not only reduces the environmental impact associated with manufacturing new materials but also reduces costs over time.

Recycling and disposal

At the end of the insulation’s life, planning for its environmentally-friendly disposal is crucial. Some insulation materials can be recycled, reducing the need for new materials and saving energy. If recycling is not an option, the material should be disposed of in a way that minimises harm. Before you choose an insulation material, research your options for recycling or disposing of it.

Let us know if there are any other strategies you use to make your project more eco-friendly!

Facebook

Twitter

LinkedIn

Your cart

Trade Account Login

We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. By clicking “Accept All”, you consent to the use of ALL the cookies. However, you may visit "Cookie Settings" to provide personalised consent.

Manage consent

Privacy Overview

This website uses cookies to improve your experience while you navigate through the website. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. We also use third-party cookies that help us analyze and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may affect your browsing experience.

Necessary cookies are absolutely essential for the website to function properly. These cookies ensure basic functionalities and security features of the website, anonymously.

| Cookie | Duration | Description |

|---|---|---|

| __stripe_mid | 1 year | This cookie is set by Stripe payment gateway. This cookie is used to enable payment on the website without storing any patment information on a server. |

| __stripe_sid | 30 minutes | This cookie is set by Stripe payment gateway. This cookie is used to enable payment on the website without storing any patment information on a server. |

| _GRECAPTCHA | 5 months 27 days | This cookie is set by the Google recaptcha service to identify bots to protect the website against malicious spam attacks. |

| apbct_cookies_test | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_page_hits | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_prev_referer | session | Functional cookie placed by CleanTalk Spam Protect to store referring IDs and prevent unauthorized spam from being sent from the website. |

| apbct_site_landing_ts | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_site_referer | 3 days | This cookie is placed by CleanTalk Spam Protect to prevent spam and to store the referrer page address which led the user to the website. |

| apbct_timestamp | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_urls | 3 days | This cookie is placed by CleanTalk Spam Protect to prevent spam and to store the addresses (urls) visited on the website. |

| AWSALBCORS | 7 days | This cookie is managed by Amazon Web Services and is used for load balancing. |

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| ct_checkjs | session | CleanTalk–Used to prevent spam on our comments and forms and acts as a complete anti-spam solution and firewall for this site. |

| ct_fkp_timestamp | session | CleanTalk sets this cookie to prevent spam on the site's comments/forms, and to act as a complete anti-spam solution and firewall for the site. |

| ct_pointer_data | session | CleanTalk sets this cookie to prevent spam on the site's comments/forms, and to act as a complete anti-spam solution and firewall for the site. |

| ct_ps_timestamp | session | CleanTalk sets this cookie to prevent spam on the site's comments/forms, and to act as a complete anti-spam solution and firewall for the site. |

| ct_sfw_pass_key | 1 month | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| ct_timezone | session | CleanTalk–Used to prevent spam on our comments and forms and acts as a complete anti-spam solution and firewall for this site. |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features.

| Cookie | Duration | Description |

|---|---|---|

| __zlcmid | 1 year | This cookie is used by Zendesk live chat and is used to store the live chat ID. |

| bcookie | 2 years | LinkedIn sets this cookie from LinkedIn share buttons and ad tags to recognize browser ID. |

| bscookie | 2 years | LinkedIn sets this cookie to store performed actions on the website. |

| lang | session | LinkedIn sets this cookie to remember a user's language setting. |

| lidc | 1 day | LinkedIn sets the lidc cookie to facilitate data center selection. |

| UserMatchHistory | 1 month | LinkedIn sets this cookie for LinkedIn Ads ID syncing. |

Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.

| Cookie | Duration | Description |

|---|---|---|

| __utma | 2 years | This cookie is set by Google Analytics and is used to distinguish users and sessions. The cookie is created when the JavaScript library executes and there are no existing __utma cookies. The cookie is updated every time data is sent to Google Analytics. |

| __utmb | 30 minutes | Google Analytics sets this cookie, to determine new sessions/visits. __utmb cookie is created when the JavaScript library executes and there are no existing __utma cookies. It is updated every time data is sent to Google Analytics. |

| __utmc | session | The cookie is set by Google Analytics and is deleted when the user closes the browser. It is used to enable interoperability with urchin.js, which is an older version of Google Analytics and is used in conjunction with the __utmb cookie to determine new sessions/visits. |

| __utmt | 10 minutes | Google Analytics sets this cookie to inhibit request rate. |

| __utmv | 2 years | The __utmv cookie is set on the user's device, to enable Google Analytics to classify the visitor. |

| __utmz | 6 months | Google Analytics sets this cookie to store the traffic source or campaign by which the visitor reached the site. |

| sib_cuid | 6 months | Purechat uses this cookie to send data to purechat.com, to connect visitors to the reservation team and track visitors to stay on portal. |

| SRM_B | 1 year 24 days | Used by Microsoft Advertising as a unique ID for visitors. |

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc.

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _gat_gtag_UA_61069204_2 | 1 minute | Set by Google to distinguish users. |

| _gat_UA-61069204-2 | 1 minute | A variation of the _gat cookie set by Google Analytics and Google Tag Manager to allow website owners to track visitor behaviour and measure site performance. The pattern element in the name contains the unique identity number of the account or website it relates to. |

| _gcl_au | 3 months | Provided by Google Tag Manager to experiment advertisement efficiency of websites using their services. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| _uetsid | 1 day | This cookies are used to collect analytical information about how visitors use the website. This information is used to compile report and improve site. |

| CONSENT | 2 years | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. These cookies track visitors across websites and collect information to provide customized ads.

| Cookie | Duration | Description |

|---|---|---|

| _fbp | 3 months | This cookie is set by Facebook to display advertisements when either on Facebook or on a digital platform powered by Facebook advertising, after visiting the website. |

| ANONCHK | 10 minutes | The ANONCHK cookie, set by Bing, is used to store a user's session ID and also verify the clicks from ads on the Bing search engine. The cookie helps in reporting and personalization as well. |

| fr | 3 months | Facebook sets this cookie to show relevant advertisements to users by tracking user behaviour across the web, on sites that have Facebook pixel or Facebook social plugin. |

| MUID | 1 year 24 days | Bing sets this cookie to recognize unique web browsers visiting Microsoft sites. This cookie is used for advertising, site analytics, and other operations. |

| NID | 6 months | NID cookie, set by Google, is used for advertising purposes; to limit the number of times the user sees an ad, to mute unwanted ads, and to measure the effectiveness of ads. |

| test_cookie | 15 minutes | The test_cookie is set by doubleclick.net and is used to determine if the user's browser supports cookies. |

| uuid | 6 months | MediaMath sets this cookie to avoid the same ads from being shown repeatedly and for relevant advertising. |

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt-remote-device-id | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt.innertube::nextId | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |

| yt.innertube::requests | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |

Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet.

| Cookie | Duration | Description |

|---|---|---|

| _clck | 1 year | No description |

| _clsk | 1 day | No description |

| _uetvid | 1 year 24 days | No description available. |

| AnalyticsSyncHistory | 1 month | No description |

| apbct_pixel_url | session | No description |

| apbct_visible_fields_0 | session | No description |

| apbct_visible_fields_1 | session | No description |

| apbct_visible_fields_10 | session | No description |

| apbct_visible_fields_2 | session | No description |

| apbct_visible_fields_3 | session | No description |

| apbct_visible_fields_4 | session | No description |

| apbct_visible_fields_5 | session | No description |

| apbct_visible_fields_6 | session | No description |

| apbct_visible_fields_7 | session | No description |

| apbct_visible_fields_8 | session | No description |

| apbct_visible_fields_9 | session | No description |

| ct_checked_emails | session | No description |

| ct_has_scrolled | session | No description |

| ct_mouse_moved | session | No description |

| ct_screen_info | session | No description |

| ictf_master | never | No description available. |

| li_gc | 2 years | No description |

| m | 2 years | No description available. |

| SM | session | No description available. |

| testinfinitycookie | session | No description |

| woocommerce_show_tax | 7 days | No description available. |

| wp_woocommerce_session_c5ac76b408021294cb56bcc27eddf8a1 | 2 days | No description |