How To Install Our Mineral Wool System – A Case Study

Our Mineral Wool system is the premier fire resistant solution to external wall insulation. We had the privilege to work with Eugene to create a high performance thermal envelope for his property. This blog will detail the steps he has undertaken to install this system. The whole process is a testament to Eugene and the EWI Pro Training Academy as he attended courses. The courses have furnished him with the skills to know how to install our Mineral Wool system.

What is the Mineral Wool system?

Mineral Wool is a fantastic product in isolation. We stock the Rockwool brand at EWI Store, but all forms have a similar composition. The material is produced by heating the volcanic rock within a large furnace, then spinning it into fibrous strands and compressing it into boards. The dual density batts provide many benefits for the property. The primary benefit is the improved thermal performance. 110mm of Rockwool achieves the desired 0.3W/(m2K). Our Mineral Wool system also offers excellent acoustic insulation, a benefit highly desirable in urban areas due to rising noise pollution. Rockwool is also non-combustible, thanks to its A1 fire rating. If a building is to set on fire, Rockwool will act as a firebreak solution, and not produce any toxic fumes.

The property is located in Staines and constitutes very intriguing architectural features. Stilts elevate the house as a form of flood prevention; moreover, the aesthetic is striking. Read on below for the ‘how’ of installing our Mineral Wool.

How to install our Mineral Wool – First step

As seen in the photo above, the substrate is new blockwork. The whole building is a new build, with the previous structure knocked down. The first step in installing EWI is the application of a basecoat layer. Eugene chose to use EWI-225 Premium Basecoat, which doubles as an adhesive and basecoat. More importantly, EWI-225 is incredibly strong and can be used as adhesive for Mineral Wool, which is the heaviest of our insulation boards. When using Premium Basecoat for the basecoat layer, apply the basecoat using a 10mm notched trowel to the substrate. Then embed overlapping pieces of Fibreglass Mesh – the mesh should sit within the middle of the basecoat layer. Once embedded the basecoat layer should be 6mm in total.

When using Premium Basecoat for the adhesive, apply to the insulation boards in either a pattern around the edges of the board with three dabs in the middle, or as a solid surface smoothed with a notched trowel. Eugene chose to cover the whole board. Our Mineral Wool boards should then be stuck to the wall in a staggered pattern, promoting strength in the construction. Eugene used 120mm of Rockwool on his property, which would achieve a U-value of under 0.3W/(m2K).

Second step

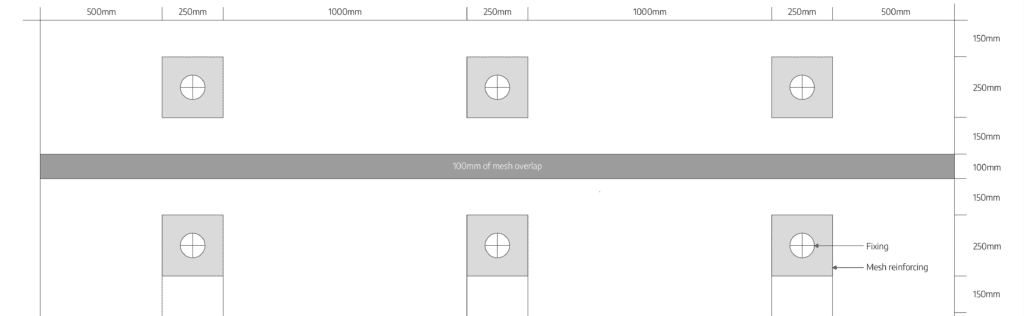

Mechanical fixings affix the boards alongside the Premium Basecoat. We would always recommend that both adhesive and fixings are part of every installation, especially in our Mineral Wool system due to the weight of the individual boards. Eugene has installed screw in fixings; we do also offer hammer in fixings. The distribution of fixings throughout each board is crucial to promote strength. The insulation boards are installed in a staggered pattern much like all brick and blockwork is. The starter track holds the insulation boards in place; Eugene chose to use aluminium starter track due to the weight of Mineral Wool, and the extended protection capabilities it provides. The clip on profile and movement beads are also installed in the first two stages. Mesh on the clip on profile, along with the UPVC material enhances the weatherproof capabilities.

Third step

The third step in Eugene’s install of our Mineral Wool system is the crucial basecoat and fibreglass mesh step. Again, Eugene used a notched trowel to apply the basecoat. When using Premium Basecoat for the basecoat layer, apply the basecoat using a 10mm notched trowel to the substrate. Then embed overlapping pieces of Fibreglass Mesh – the mesh should sit within the middle of the basecoat layer. Once embedded, the basecoat layer should be 6mm in total.

Stress patches of fibreglass mesh are also crucial to install around the fixings and around window reveals. The black marker on the fibreglass mesh indicates the overlap required. The combination of our Premium Basecoat and Fibreglass Mesh results in a smooth finish, high in tensile strength, which is ready to receive a layer of thin coat render.

Fourth step

The final step in the process of installing our Mineral Wool system is the application of the thin coat render or ‘topcoat’. Topcoat tends to be a fairly broad term for describing the final finish on a façade, and there are various options. We stock a range of silicone renders and Monocouche Render, as well as Acrylic and Mineral renders. Eugene has used our Premium Bio Silicone Render in 20001 Pure White, which is our most popular finish.

Premium Bio Silicone Render is the most progressive render in the EWI Pro catalogue, offering end-users an advanced range of benefits. What really sets this render apart is its ability to actively break down any sign of organic growth that occurs on the render surface. Premium Bio Silicone offers an enhanced level of impact resistance, especially when used with a fibreglass mesh-reinforced basecoat layer. It also offers increased resistance to UV rays, which means that the coloured render will not fade over time; even the brightest of colours will stay vibrant for years to come! As the property is located on the banks of a river, Premium Bio Silicone Render will actively break down any signs of organic growth which the house will be more susceptible to.

Fourth step – Application stage

Eugene used our Topcoat Primer prior to applying render. This provides several benefits; firstly it aids adhesion between the render and the basecoat. Secondly it limits the absorption of the basecoat layer, ensuring the render cures properly – this is especially important during the summer months, giving the installer time to get a finish on the render. Finally, we can tint the Topcoat Primer in the same colour as the render. This ensures that there is no basecoat bleed through.

Eugene applied the Topcoat Primer with a simple paint roller. However, application of the Silicone Render is done with a smooth trowel. It should be applied in small areas, and smoothed with a trowel. Then, use a plastic float to apply the render in a circular motion to achieve your desired finish. We have recently teamed up with Skill Builder to compile a guide video detailing how to install a whole EWI system. The Silicone Render portion starts at 16:58 of the below video. Roger and our very own Paul detail certain techniques to follow during the application of your Silicone Render.

https://www.youtube.com/watch?v=96WN8AtAvNg

Eugene followed the same process as detailed above, and as you can see in the images below!

The result is an incredibly smooth and consistent finish, creating a visually impressive envelope for Eugene’s property. This neatly summarises the stages of how to install our Mineral Wool system.

Final thoughts

Eugene collaborated extensively with EWI Pro’s Business Development Team in regards to figuring out a plan for the property. His testimonial is below!

We’d also like to take this opportunity to thank him for allowing us the opportunity to film the process of his project. It’s a fantastic testament to him, the Training Academy, and our products.

If you have a project in the planning stages or ongoing, and require any advice, give our sales team a call. We would also love to see our products and systems being used, so get in touch with the Marketing Team via Instagram, Facebook, Twitter, or email us at [email protected]!

Facebook

Twitter

LinkedIn

Your cart

Trade Account Login

We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. By clicking “Accept All”, you consent to the use of ALL the cookies. However, you may visit "Cookie Settings" to provide personalised consent.

Manage consent

Privacy Overview

This website uses cookies to improve your experience while you navigate through the website. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. We also use third-party cookies that help us analyze and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may affect your browsing experience.

Necessary cookies are absolutely essential for the website to function properly. These cookies ensure basic functionalities and security features of the website, anonymously.

| Cookie | Duration | Description |

|---|---|---|

| __stripe_mid | 1 year | This cookie is set by Stripe payment gateway. This cookie is used to enable payment on the website without storing any patment information on a server. |

| __stripe_sid | 30 minutes | This cookie is set by Stripe payment gateway. This cookie is used to enable payment on the website without storing any patment information on a server. |

| _GRECAPTCHA | 5 months 27 days | This cookie is set by the Google recaptcha service to identify bots to protect the website against malicious spam attacks. |

| apbct_cookies_test | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_page_hits | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_prev_referer | session | Functional cookie placed by CleanTalk Spam Protect to store referring IDs and prevent unauthorized spam from being sent from the website. |

| apbct_site_landing_ts | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_site_referer | 3 days | This cookie is placed by CleanTalk Spam Protect to prevent spam and to store the referrer page address which led the user to the website. |

| apbct_timestamp | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_urls | 3 days | This cookie is placed by CleanTalk Spam Protect to prevent spam and to store the addresses (urls) visited on the website. |

| AWSALBCORS | 7 days | This cookie is managed by Amazon Web Services and is used for load balancing. |

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| ct_checkjs | session | CleanTalk–Used to prevent spam on our comments and forms and acts as a complete anti-spam solution and firewall for this site. |

| ct_fkp_timestamp | session | CleanTalk sets this cookie to prevent spam on the site's comments/forms, and to act as a complete anti-spam solution and firewall for the site. |

| ct_pointer_data | session | CleanTalk sets this cookie to prevent spam on the site's comments/forms, and to act as a complete anti-spam solution and firewall for the site. |

| ct_ps_timestamp | session | CleanTalk sets this cookie to prevent spam on the site's comments/forms, and to act as a complete anti-spam solution and firewall for the site. |

| ct_sfw_pass_key | 1 month | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| ct_timezone | session | CleanTalk–Used to prevent spam on our comments and forms and acts as a complete anti-spam solution and firewall for this site. |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features.

| Cookie | Duration | Description |

|---|---|---|

| __zlcmid | 1 year | This cookie is used by Zendesk live chat and is used to store the live chat ID. |

| bcookie | 2 years | LinkedIn sets this cookie from LinkedIn share buttons and ad tags to recognize browser ID. |

| bscookie | 2 years | LinkedIn sets this cookie to store performed actions on the website. |

| lang | session | LinkedIn sets this cookie to remember a user's language setting. |

| lidc | 1 day | LinkedIn sets the lidc cookie to facilitate data center selection. |

| UserMatchHistory | 1 month | LinkedIn sets this cookie for LinkedIn Ads ID syncing. |

Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.

| Cookie | Duration | Description |

|---|---|---|

| __utma | 2 years | This cookie is set by Google Analytics and is used to distinguish users and sessions. The cookie is created when the JavaScript library executes and there are no existing __utma cookies. The cookie is updated every time data is sent to Google Analytics. |

| __utmb | 30 minutes | Google Analytics sets this cookie, to determine new sessions/visits. __utmb cookie is created when the JavaScript library executes and there are no existing __utma cookies. It is updated every time data is sent to Google Analytics. |

| __utmc | session | The cookie is set by Google Analytics and is deleted when the user closes the browser. It is used to enable interoperability with urchin.js, which is an older version of Google Analytics and is used in conjunction with the __utmb cookie to determine new sessions/visits. |

| __utmt | 10 minutes | Google Analytics sets this cookie to inhibit request rate. |

| __utmv | 2 years | The __utmv cookie is set on the user's device, to enable Google Analytics to classify the visitor. |

| __utmz | 6 months | Google Analytics sets this cookie to store the traffic source or campaign by which the visitor reached the site. |

| sib_cuid | 6 months | Purechat uses this cookie to send data to purechat.com, to connect visitors to the reservation team and track visitors to stay on portal. |

| SRM_B | 1 year 24 days | Used by Microsoft Advertising as a unique ID for visitors. |

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc.

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _gat_gtag_UA_61069204_2 | 1 minute | Set by Google to distinguish users. |

| _gat_UA-61069204-2 | 1 minute | A variation of the _gat cookie set by Google Analytics and Google Tag Manager to allow website owners to track visitor behaviour and measure site performance. The pattern element in the name contains the unique identity number of the account or website it relates to. |

| _gcl_au | 3 months | Provided by Google Tag Manager to experiment advertisement efficiency of websites using their services. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| _uetsid | 1 day | This cookies are used to collect analytical information about how visitors use the website. This information is used to compile report and improve site. |

| CONSENT | 2 years | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. These cookies track visitors across websites and collect information to provide customized ads.

| Cookie | Duration | Description |

|---|---|---|

| _fbp | 3 months | This cookie is set by Facebook to display advertisements when either on Facebook or on a digital platform powered by Facebook advertising, after visiting the website. |

| ANONCHK | 10 minutes | The ANONCHK cookie, set by Bing, is used to store a user's session ID and also verify the clicks from ads on the Bing search engine. The cookie helps in reporting and personalization as well. |

| fr | 3 months | Facebook sets this cookie to show relevant advertisements to users by tracking user behaviour across the web, on sites that have Facebook pixel or Facebook social plugin. |

| MUID | 1 year 24 days | Bing sets this cookie to recognize unique web browsers visiting Microsoft sites. This cookie is used for advertising, site analytics, and other operations. |

| NID | 6 months | NID cookie, set by Google, is used for advertising purposes; to limit the number of times the user sees an ad, to mute unwanted ads, and to measure the effectiveness of ads. |

| test_cookie | 15 minutes | The test_cookie is set by doubleclick.net and is used to determine if the user's browser supports cookies. |

| uuid | 6 months | MediaMath sets this cookie to avoid the same ads from being shown repeatedly and for relevant advertising. |

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt-remote-device-id | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt.innertube::nextId | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |

| yt.innertube::requests | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |

Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet.

| Cookie | Duration | Description |

|---|---|---|

| _clck | 1 year | No description |

| _clsk | 1 day | No description |

| _uetvid | 1 year 24 days | No description available. |

| AnalyticsSyncHistory | 1 month | No description |

| apbct_pixel_url | session | No description |

| apbct_visible_fields_0 | session | No description |

| apbct_visible_fields_1 | session | No description |

| apbct_visible_fields_10 | session | No description |

| apbct_visible_fields_2 | session | No description |

| apbct_visible_fields_3 | session | No description |

| apbct_visible_fields_4 | session | No description |

| apbct_visible_fields_5 | session | No description |

| apbct_visible_fields_6 | session | No description |

| apbct_visible_fields_7 | session | No description |

| apbct_visible_fields_8 | session | No description |

| apbct_visible_fields_9 | session | No description |

| ct_checked_emails | session | No description |

| ct_has_scrolled | session | No description |

| ct_mouse_moved | session | No description |

| ct_screen_info | session | No description |

| ictf_master | never | No description available. |

| li_gc | 2 years | No description |

| m | 2 years | No description available. |

| SM | session | No description available. |

| testinfinitycookie | session | No description |

| woocommerce_show_tax | 7 days | No description available. |

| wp_woocommerce_session_c5ac76b408021294cb56bcc27eddf8a1 | 2 days | No description |