How to fix cracked render

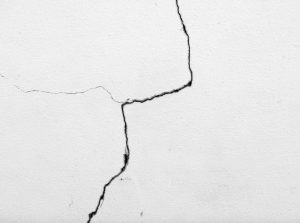

While sand and cement render is still commonplace on many properties throughout the UK, it has one major issue: it is prone to cracking.

Traditionally six parts sand and one part lime, sand and cement render is typically applied at a thickness of around 20mm and coated with masonry paint to complete the look. While lime can enhance flexibility, this render is still not flexible enough to withstand natural movements of a building (namely, expanding in the summer and shrinking in the winter), therefore causing ‘hairline’ cracks.

Such cracks can not only impact the overall aesthetic of a property but also lead to water ingress, causing further issues down the line, including dampness, heat loss and mould. If you’ve noticed cracks of any kind on the façade of your property, you’ve come to the right place as we’re going to explain how to fix cracked render.

If you’ve read our blog comparing sand and cement and thin-coat render systems, you’ll know that thin-coat renders are extremely flexible and therefore far less likely to crack than sand and cement render. As mentioned, sand and cement render is typically applied at a thickness of around 20mm; in contrast, thin-coat renders are exactly that: thin-coat, meaning that they range from 6-7mm in thickness depending on the grain size chosen.

What’s more, our thin-coat render systems are comprised of a flexible basecoat, embedded with fibreglass mesh for extra strength and crack resistance, then finished with a thin-coat render for a smooth, aesthetically pleasing finish. Going forward, we highly recommend choosing a thin-coat render system as their flexibility, durability and crack resistance is second to none.

Depending on the size, severity and stage of development of the crack(s) on your property, there are several options for fixing cracked render.

1. Fixing completely damaged render

If the render is damaged all over (namely, full of cracks or peeling away), you have three options:

Start again – remove the existing render!

The best solution for fixing cracked render is to start again! While this might not be what you wanted to hear, putting any other materials on top of cracked render is akin to using glue: it is only a temporary fix and, over time, the cracks will only continue to expand and worsen. Therefore, we always recommend stripping the existing render back to the brickwork, but we appreciate this may not be an option due to the time and cost implications.

Add a thin layer of EPS insulation

The next best solution is to add a thin layer of EPS insulation (20mm or 30mm) to the wall; this first needs to be attached with adhesive, then anchored using mechanical fixings. Before adding the insulation board, try to remove any very loose render and make good the surface with a Levelling Mortar. Then, once the insulation boards are in place and the adhesive has set, you need to use mechancial fixings. The fixings need to be of a sufficient length to go through the insulation, through the existing render and go about 40mm into the underlying substrate (typically brick or block). This system is a great solution because the The EPS is anchored in place by the mechancial fixings – which ties the existing render to the wall, even if it were to fail in the years to come.

Once the insulation boards are in place, apply a 6mm-thick basecoat layer with embedded reinforcing fibreglass mesh followed by a thin-coat render topcoat to provide a decorative finish. For more information on how much this render system typically costs, be sure to check out this blog on the cost of coloured render per square metre.

Essentially, applying a thin layer of EPS means that you are creating a new, stable substrate onto which you can apply the thin-coat render system. Also, it means that you will boost the thermal performance of your home, albeit this is relative to the thickness of the layer of insulation.

Use Scrim and Pin Fixings

Scrim and pin fixings are used to anchor the basecoat to the existing render. Once the basecoat is applied to the existing render surface, then mechanical fixings are hammered into placce through the fibreglass mesh. The fixing holes need to be drilled in to the wall while the basecoat is still wet.

Once the fixings have been hammered in to place (we recommend 1 fixing for each m2), 300mm x 300mm patches of mesh need to be basecoated over the fixing.

2. Fixing cracked render on just one panel

If only one panel – that is, one side of the house – is cracked, we recommend first filling the crack with our Levelling Mortar, then applying a fresh layer of EWI-225 Premium Basecoat and a topcoat render to that one panel. Hopefully, the panel in which the crack has occurred doesn’t comprise the whole side of the house caused naturally by, for instance, a downpipe, which can disguise where the new render meets the old render. The breathability of the basecoat, combined with the flexibility of the render topcoat, should provide a crack-free solution.

3. Fixing small cracks

There are some cases where a very small crack has occurred that needs fixing; for example, when a car has ‘gently’ hit the wall. In this situation, you have a couple of options.

Firstly, you can remove a square of render around the affected area and apply a basecoat and render topcoat to this area. This involves taking an angle grinder and cutting a clean square around the impacted area. The downside to this option, however, is that scarring where the new render meets the old render is inevitable as a consequence of the thinness of the new render. The square, marked out using rendering tape, ensures that the scar looks neat regardless.

The other solution for fixing a small crack is to apply a basecoat to the whole panel and re-render the property; again, this requires a bit more work, but you won’t be able to see where the original crack in the render was. This provides a nicer finish than marking out the square (as above).

We often see customers order additional buckets of render to make repairs on cracked or damaged render to simply ‘touch up’ the affected area but, 99% of the time, this will result in unsightly, visible scarring. That’s why we always recommend following one of the methods described in this blog depending on your circumstances.

At EWI Store, we are very happy to provide help with cracked render. The best way to resolve this is to send photos to [email protected] so that we can provide bespoke, expert advice on how to best fix the cracked render!

If you need a quote for materials to repair damaged render, please email us on [email protected]

Facebook

Twitter

LinkedIn

Your cart

Trade Account Login

We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. By clicking “Accept All”, you consent to the use of ALL the cookies. However, you may visit "Cookie Settings" to provide personalised consent.

Manage consent

Privacy Overview

This website uses cookies to improve your experience while you navigate through the website. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. We also use third-party cookies that help us analyze and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may affect your browsing experience.

Necessary cookies are absolutely essential for the website to function properly. These cookies ensure basic functionalities and security features of the website, anonymously.

| Cookie | Duration | Description |

|---|---|---|

| __stripe_mid | 1 year | This cookie is set by Stripe payment gateway. This cookie is used to enable payment on the website without storing any patment information on a server. |

| __stripe_sid | 30 minutes | This cookie is set by Stripe payment gateway. This cookie is used to enable payment on the website without storing any patment information on a server. |

| _GRECAPTCHA | 5 months 27 days | This cookie is set by the Google recaptcha service to identify bots to protect the website against malicious spam attacks. |

| apbct_cookies_test | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_page_hits | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_prev_referer | session | Functional cookie placed by CleanTalk Spam Protect to store referring IDs and prevent unauthorized spam from being sent from the website. |

| apbct_site_landing_ts | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_site_referer | 3 days | This cookie is placed by CleanTalk Spam Protect to prevent spam and to store the referrer page address which led the user to the website. |

| apbct_timestamp | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_urls | 3 days | This cookie is placed by CleanTalk Spam Protect to prevent spam and to store the addresses (urls) visited on the website. |

| AWSALBCORS | 7 days | This cookie is managed by Amazon Web Services and is used for load balancing. |

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| ct_checkjs | session | CleanTalk–Used to prevent spam on our comments and forms and acts as a complete anti-spam solution and firewall for this site. |

| ct_fkp_timestamp | session | CleanTalk sets this cookie to prevent spam on the site's comments/forms, and to act as a complete anti-spam solution and firewall for the site. |

| ct_pointer_data | session | CleanTalk sets this cookie to prevent spam on the site's comments/forms, and to act as a complete anti-spam solution and firewall for the site. |

| ct_ps_timestamp | session | CleanTalk sets this cookie to prevent spam on the site's comments/forms, and to act as a complete anti-spam solution and firewall for the site. |

| ct_sfw_pass_key | 1 month | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| ct_timezone | session | CleanTalk–Used to prevent spam on our comments and forms and acts as a complete anti-spam solution and firewall for this site. |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features.

| Cookie | Duration | Description |

|---|---|---|

| __zlcmid | 1 year | This cookie is used by Zendesk live chat and is used to store the live chat ID. |

| bcookie | 2 years | LinkedIn sets this cookie from LinkedIn share buttons and ad tags to recognize browser ID. |

| bscookie | 2 years | LinkedIn sets this cookie to store performed actions on the website. |

| lang | session | LinkedIn sets this cookie to remember a user's language setting. |

| lidc | 1 day | LinkedIn sets the lidc cookie to facilitate data center selection. |

| UserMatchHistory | 1 month | LinkedIn sets this cookie for LinkedIn Ads ID syncing. |

Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.

| Cookie | Duration | Description |

|---|---|---|

| __utma | 2 years | This cookie is set by Google Analytics and is used to distinguish users and sessions. The cookie is created when the JavaScript library executes and there are no existing __utma cookies. The cookie is updated every time data is sent to Google Analytics. |

| __utmb | 30 minutes | Google Analytics sets this cookie, to determine new sessions/visits. __utmb cookie is created when the JavaScript library executes and there are no existing __utma cookies. It is updated every time data is sent to Google Analytics. |

| __utmc | session | The cookie is set by Google Analytics and is deleted when the user closes the browser. It is used to enable interoperability with urchin.js, which is an older version of Google Analytics and is used in conjunction with the __utmb cookie to determine new sessions/visits. |

| __utmt | 10 minutes | Google Analytics sets this cookie to inhibit request rate. |

| __utmv | 2 years | The __utmv cookie is set on the user's device, to enable Google Analytics to classify the visitor. |

| __utmz | 6 months | Google Analytics sets this cookie to store the traffic source or campaign by which the visitor reached the site. |

| sib_cuid | 6 months | Purechat uses this cookie to send data to purechat.com, to connect visitors to the reservation team and track visitors to stay on portal. |

| SRM_B | 1 year 24 days | Used by Microsoft Advertising as a unique ID for visitors. |

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc.

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _gat_gtag_UA_61069204_2 | 1 minute | Set by Google to distinguish users. |

| _gat_UA-61069204-2 | 1 minute | A variation of the _gat cookie set by Google Analytics and Google Tag Manager to allow website owners to track visitor behaviour and measure site performance. The pattern element in the name contains the unique identity number of the account or website it relates to. |

| _gcl_au | 3 months | Provided by Google Tag Manager to experiment advertisement efficiency of websites using their services. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| _uetsid | 1 day | This cookies are used to collect analytical information about how visitors use the website. This information is used to compile report and improve site. |

| CONSENT | 2 years | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. These cookies track visitors across websites and collect information to provide customized ads.

| Cookie | Duration | Description |

|---|---|---|

| _fbp | 3 months | This cookie is set by Facebook to display advertisements when either on Facebook or on a digital platform powered by Facebook advertising, after visiting the website. |

| ANONCHK | 10 minutes | The ANONCHK cookie, set by Bing, is used to store a user's session ID and also verify the clicks from ads on the Bing search engine. The cookie helps in reporting and personalization as well. |

| fr | 3 months | Facebook sets this cookie to show relevant advertisements to users by tracking user behaviour across the web, on sites that have Facebook pixel or Facebook social plugin. |

| MUID | 1 year 24 days | Bing sets this cookie to recognize unique web browsers visiting Microsoft sites. This cookie is used for advertising, site analytics, and other operations. |

| NID | 6 months | NID cookie, set by Google, is used for advertising purposes; to limit the number of times the user sees an ad, to mute unwanted ads, and to measure the effectiveness of ads. |

| test_cookie | 15 minutes | The test_cookie is set by doubleclick.net and is used to determine if the user's browser supports cookies. |

| uuid | 6 months | MediaMath sets this cookie to avoid the same ads from being shown repeatedly and for relevant advertising. |

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt-remote-device-id | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt.innertube::nextId | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |

| yt.innertube::requests | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |

Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet.

| Cookie | Duration | Description |

|---|---|---|

| _clck | 1 year | No description |

| _clsk | 1 day | No description |

| _uetvid | 1 year 24 days | No description available. |

| AnalyticsSyncHistory | 1 month | No description |

| apbct_pixel_url | session | No description |

| apbct_visible_fields_0 | session | No description |

| apbct_visible_fields_1 | session | No description |

| apbct_visible_fields_10 | session | No description |

| apbct_visible_fields_2 | session | No description |

| apbct_visible_fields_3 | session | No description |

| apbct_visible_fields_4 | session | No description |

| apbct_visible_fields_5 | session | No description |

| apbct_visible_fields_6 | session | No description |

| apbct_visible_fields_7 | session | No description |

| apbct_visible_fields_8 | session | No description |

| apbct_visible_fields_9 | session | No description |

| ct_checked_emails | session | No description |

| ct_has_scrolled | session | No description |

| ct_mouse_moved | session | No description |

| ct_screen_info | session | No description |

| ictf_master | never | No description available. |

| li_gc | 2 years | No description |

| m | 2 years | No description available. |

| SM | session | No description available. |

| testinfinitycookie | session | No description |

| woocommerce_show_tax | 7 days | No description available. |

| wp_woocommerce_session_c5ac76b408021294cb56bcc27eddf8a1 | 2 days | No description |

One thought on “How to fix cracked render”

Always recommend using EWI-225 premium adhesive for fixing cracked render – basically this is our strongest adhesive and so is perfect for providing a really strong, flexible basecoat layer. You may need to remove any blown render first and where there are now gaps in the render, use our EWI-260 levelling mortar, so you are working with a flat surface to start with.

Remember always try and get the basecoat layer as smooth as possible to ensure the thin coat render can easily be applied at the end of the job.