How to Install Elastolith Brick Slips

Brick slips are a great way to achieve the brick appearance without the fuss! Customers always ask us for guidance on installing Elastolith brick slips, so we’ve put together this blog, which details the benefits over other brick slips and how to install them.

What are Brick slips?

Several brick slips exist, including clinker, cement, and acrylic slips. They are all designed to do the same thing, though, and they mimic the look of brickwork. Real bricks aren’t used with modern construction methods, as they speed up the building process and are often cheaper. Brick slips can recreate the brick look regardless of the construction method.

Elastolith brick slips are made from acrylic, a type of plastic. They are lightweight, flexible, and durable. Still, perhaps more importantly, their finished appearance perfectly resembles a real brick, which is why they are a great alternative to achieving the brick aesthetic without the cost and time required to build a real brick wall. There are other benefits to using Elastolith brick slips; they are acrylic and can be cut to size with household scissors. This is particularly beneficial when working around corners. As the brick pattern is staggered, the corners inevitably require a smaller portion of brick slips.

-

Elabrick Brick Slips – Alaska

From £35.39 Incl. VATFrom £29.49 Excl. VAT -

Elabrick Brick Slips – Blackpool

From £35.39 Incl. VATFrom £29.49 Excl. VAT -

Elabrick Brick Slips – Colorado

From £35.39 Incl. VATFrom £29.49 Excl. VAT -

Elabrick Brick Slips – Cordoba

From £35.39 Incl. VATFrom £29.49 Excl. VAT -

Elabrick Brick Slips – Corsica

Rated 4.00 out of 5From £35.39 Incl. VATFrom £29.49 Excl. VAT -

Elabrick Brick Slips – Nebraska

Rated 5.00 out of 5From £35.39 Incl. VATFrom £29.49 Excl. VAT

Clinker brick slips

Clinker bricks are made from clay and are fired at very high temperatures, resulting in a dense, hard, and sometimes slightly irregular product. The high-temperature firing gives them a distinctive dark colour, often somewhat burnt. Clinker brick slips have a rough texture and a unique, rustic look, often associated with old industrial buildings. The colours can range from dark browns and reds to almost black, with a lot of natural variation. They are also highly durable and weather-resistant, making them suitable for interior and exterior applications.

Clinker brick slips are commonly used in restoration projects or to give new buildings a vintage or industrial look.

Cement brick slips

Cement brick slips, as the name suggests, are made from cement and other aggregates. They are manufactured to replicate the look of traditional bricks. These brick slips can be designed to mimic various types of brick finishes, including those of clay bricks, but they are often more uniform in appearance than clinker bricks. They can be made in a wide range of colours and textures. While generally durable, cement brick slips may not be as weather-resistant as clinker brick slips. However, they are typically more consistent in quality and appearance due to the controlled manufacturing process. Cement brick slips are versatile and can be used in modern and traditional designs. They are suitable for interior walls, fireplaces, or exterior cladding.

Preparing the wall

Clear all dirt and debris away from the substrate to prepare for installing Elastolith brick slips. The surface must be able to take the load and be free from stress. We recommend using our EWI-310 primer on any substrate before applying the acrylic brick slips because it creates a nice mechanical key to which the brick slip adhesive can adhere.

We also recommend covering any floors or surfaces to protect them before application. If installing internally, plug sockets can also be removed and reattached afterward, but we recommend an electrical professional do this. It is advised to have all your tools and products readily available as this will help with ease of application.

-

Universal Primer (EWI-310) – 20kg

Rated 4.40 out of 5£64.82 Incl. VAT£54.02 Excl. VAT£72.04 Incl. VAT£60.03 Excl. VAT

Planning the layout

Before starting the brick slip application, we suggest planning the layout and ensuring all measurements are correct so there are no uneven sides or large mortar joints on show. We recommend starting at the bottom and working horizontally, ensuring the distance between each brick slip is even.

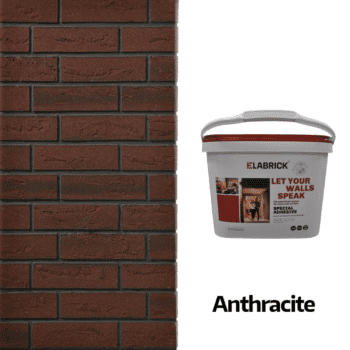

Elastolith Brick slip adhesive comes ready to use

The Brick slip adhesive has been formulated to have a high bond strength, securing brick slips into place. It is a ready-to-use product sold in four different colours: anthracite, cement grey, light grey, and white. This allows you to choose the perfect coloured grout for your brick slips.

-

Elabrick Special Adhesive (15kg Tub)

From £71.99 Incl. VATFrom £50.39 Incl. VATFrom £41.99 Excl. VAT

Sticking the Brick slips to the substrate

Once you have primed the wall with the EWI-310, it is time to apply the brick slips! Elastolith adhesive should be applied vertically using a 4mm notched trowel and flattened to 1.5-2.0mm. We recommend only applying the adhesive to a small area to ensure it does not dry out before the brick slips are applied. Once applied, press the brick slip into the wet adhesive, which should be fully embedded in the adhesive. If you want to check the adhesive coverage, pull the brick slip off whilst the adhesive is still wet and check that the whole surface is covered. Once the brick slips have been applied, it is time to grout! With Elastolith brickslips, the adhesive also acts as the grout; hence, it comes in different colours.

To achieve the ‘grout look’ between the brick slips, use a slightly damp brush to smooth the adhesive at the joins. This needs to be done promptly to ensure the adhesive is still wet and, therefore, workable. We recommend smoothing the outer joins first, then the inner join with long strokes. Ensure sufficient adhesive is on the sides of the brick slip to prevent water from getting behind them.

If brick slips are applied externally, they must be protected against wind and rain for at least three days after being applied to the substrate. Temperature and humidity may slightly impact this timeframe.

Learn more about Elastolith Brick slips

If you want to explore brick slips in more detail, why not check out our blog, ‘Advantages of Brick Slips’? You can always call our friendly sales team, who would happily discuss any products in more detail.

Facebook

Twitter

LinkedIn

Your cart

Trade Account Login

We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. By clicking “Accept All”, you consent to the use of ALL the cookies. However, you may visit "Cookie Settings" to provide personalised consent.

Manage consent

Privacy Overview

This website uses cookies to improve your experience while you navigate through the website. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. We also use third-party cookies that help us analyze and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may affect your browsing experience.

Necessary cookies are absolutely essential for the website to function properly. These cookies ensure basic functionalities and security features of the website, anonymously.

| Cookie | Duration | Description |

|---|---|---|

| __stripe_mid | 1 year | This cookie is set by Stripe payment gateway. This cookie is used to enable payment on the website without storing any patment information on a server. |

| __stripe_sid | 30 minutes | This cookie is set by Stripe payment gateway. This cookie is used to enable payment on the website without storing any patment information on a server. |

| _GRECAPTCHA | 5 months 27 days | This cookie is set by the Google recaptcha service to identify bots to protect the website against malicious spam attacks. |

| apbct_cookies_test | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_page_hits | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_prev_referer | session | Functional cookie placed by CleanTalk Spam Protect to store referring IDs and prevent unauthorized spam from being sent from the website. |

| apbct_site_landing_ts | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_site_referer | 3 days | This cookie is placed by CleanTalk Spam Protect to prevent spam and to store the referrer page address which led the user to the website. |

| apbct_timestamp | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_urls | 3 days | This cookie is placed by CleanTalk Spam Protect to prevent spam and to store the addresses (urls) visited on the website. |

| AWSALBCORS | 7 days | This cookie is managed by Amazon Web Services and is used for load balancing. |

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| ct_checkjs | session | CleanTalk–Used to prevent spam on our comments and forms and acts as a complete anti-spam solution and firewall for this site. |

| ct_fkp_timestamp | session | CleanTalk sets this cookie to prevent spam on the site's comments/forms, and to act as a complete anti-spam solution and firewall for the site. |

| ct_pointer_data | session | CleanTalk sets this cookie to prevent spam on the site's comments/forms, and to act as a complete anti-spam solution and firewall for the site. |

| ct_ps_timestamp | session | CleanTalk sets this cookie to prevent spam on the site's comments/forms, and to act as a complete anti-spam solution and firewall for the site. |

| ct_sfw_pass_key | 1 month | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| ct_timezone | session | CleanTalk–Used to prevent spam on our comments and forms and acts as a complete anti-spam solution and firewall for this site. |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features.

| Cookie | Duration | Description |

|---|---|---|

| __zlcmid | 1 year | This cookie is used by Zendesk live chat and is used to store the live chat ID. |

| bcookie | 2 years | LinkedIn sets this cookie from LinkedIn share buttons and ad tags to recognize browser ID. |

| bscookie | 2 years | LinkedIn sets this cookie to store performed actions on the website. |

| lang | session | LinkedIn sets this cookie to remember a user's language setting. |

| lidc | 1 day | LinkedIn sets the lidc cookie to facilitate data center selection. |

| UserMatchHistory | 1 month | LinkedIn sets this cookie for LinkedIn Ads ID syncing. |

Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.

| Cookie | Duration | Description |

|---|---|---|

| __utma | 2 years | This cookie is set by Google Analytics and is used to distinguish users and sessions. The cookie is created when the JavaScript library executes and there are no existing __utma cookies. The cookie is updated every time data is sent to Google Analytics. |

| __utmb | 30 minutes | Google Analytics sets this cookie, to determine new sessions/visits. __utmb cookie is created when the JavaScript library executes and there are no existing __utma cookies. It is updated every time data is sent to Google Analytics. |

| __utmc | session | The cookie is set by Google Analytics and is deleted when the user closes the browser. It is used to enable interoperability with urchin.js, which is an older version of Google Analytics and is used in conjunction with the __utmb cookie to determine new sessions/visits. |

| __utmt | 10 minutes | Google Analytics sets this cookie to inhibit request rate. |

| __utmv | 2 years | The __utmv cookie is set on the user's device, to enable Google Analytics to classify the visitor. |

| __utmz | 6 months | Google Analytics sets this cookie to store the traffic source or campaign by which the visitor reached the site. |

| sib_cuid | 6 months | Purechat uses this cookie to send data to purechat.com, to connect visitors to the reservation team and track visitors to stay on portal. |

| SRM_B | 1 year 24 days | Used by Microsoft Advertising as a unique ID for visitors. |

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc.

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _gat_gtag_UA_61069204_2 | 1 minute | Set by Google to distinguish users. |

| _gat_UA-61069204-2 | 1 minute | A variation of the _gat cookie set by Google Analytics and Google Tag Manager to allow website owners to track visitor behaviour and measure site performance. The pattern element in the name contains the unique identity number of the account or website it relates to. |

| _gcl_au | 3 months | Provided by Google Tag Manager to experiment advertisement efficiency of websites using their services. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| _uetsid | 1 day | This cookies are used to collect analytical information about how visitors use the website. This information is used to compile report and improve site. |

| CONSENT | 2 years | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. These cookies track visitors across websites and collect information to provide customized ads.

| Cookie | Duration | Description |

|---|---|---|

| _fbp | 3 months | This cookie is set by Facebook to display advertisements when either on Facebook or on a digital platform powered by Facebook advertising, after visiting the website. |

| ANONCHK | 10 minutes | The ANONCHK cookie, set by Bing, is used to store a user's session ID and also verify the clicks from ads on the Bing search engine. The cookie helps in reporting and personalization as well. |

| fr | 3 months | Facebook sets this cookie to show relevant advertisements to users by tracking user behaviour across the web, on sites that have Facebook pixel or Facebook social plugin. |

| MUID | 1 year 24 days | Bing sets this cookie to recognize unique web browsers visiting Microsoft sites. This cookie is used for advertising, site analytics, and other operations. |

| NID | 6 months | NID cookie, set by Google, is used for advertising purposes; to limit the number of times the user sees an ad, to mute unwanted ads, and to measure the effectiveness of ads. |

| test_cookie | 15 minutes | The test_cookie is set by doubleclick.net and is used to determine if the user's browser supports cookies. |

| uuid | 6 months | MediaMath sets this cookie to avoid the same ads from being shown repeatedly and for relevant advertising. |

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt-remote-device-id | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt.innertube::nextId | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |

| yt.innertube::requests | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |

Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet.

| Cookie | Duration | Description |

|---|---|---|

| _clck | 1 year | No description |

| _clsk | 1 day | No description |

| _uetvid | 1 year 24 days | No description available. |

| AnalyticsSyncHistory | 1 month | No description |

| apbct_pixel_url | session | No description |

| apbct_visible_fields_0 | session | No description |

| apbct_visible_fields_1 | session | No description |

| apbct_visible_fields_10 | session | No description |

| apbct_visible_fields_2 | session | No description |

| apbct_visible_fields_3 | session | No description |

| apbct_visible_fields_4 | session | No description |

| apbct_visible_fields_5 | session | No description |

| apbct_visible_fields_6 | session | No description |

| apbct_visible_fields_7 | session | No description |

| apbct_visible_fields_8 | session | No description |

| apbct_visible_fields_9 | session | No description |

| ct_checked_emails | session | No description |

| ct_has_scrolled | session | No description |

| ct_mouse_moved | session | No description |

| ct_screen_info | session | No description |

| ictf_master | never | No description available. |

| li_gc | 2 years | No description |

| m | 2 years | No description available. |

| SM | session | No description available. |

| testinfinitycookie | session | No description |

| woocommerce_show_tax | 7 days | No description available. |

| wp_woocommerce_session_c5ac76b408021294cb56bcc27eddf8a1 | 2 days | No description |

2 thoughts on “How to Install Elastolith Brick Slips”

Hi I’m looking at the acrylic brick slips, is there a filler same colour as the brick slips if you need to form your own corner foe example

Hi David, we do offer the adhesive is 5 colours which are pretty closely matched to the brick slips. You can cut and shape the brick slips to your liking as well so forming any corners is simple.