U-Values And R-Values Simplified

The concept of U-value and R-value in relation to external wall insulation is nothing new. However, it can seem like a daunting prospect to wrap your head around. There are several theoretical concepts behind the calculations. We will discuss U-values, R-values, and lambda values in today’s blog.

What are U-values?

U-value is often referred to as thermal transmittance. In essence, it stands for the rate of transfer of heat through a material. When examined as a sum, the U-value stands for the combined thermal resistances of the layers that make up the entire construction; this includes walls, windows, doors, the roof, and the floor. Great consideration is also taken to include adjustments for any fixings and air gaps. These are thermal bridges or cold bridges, which present an avenue for heat to transfer away from the thermal envelope.

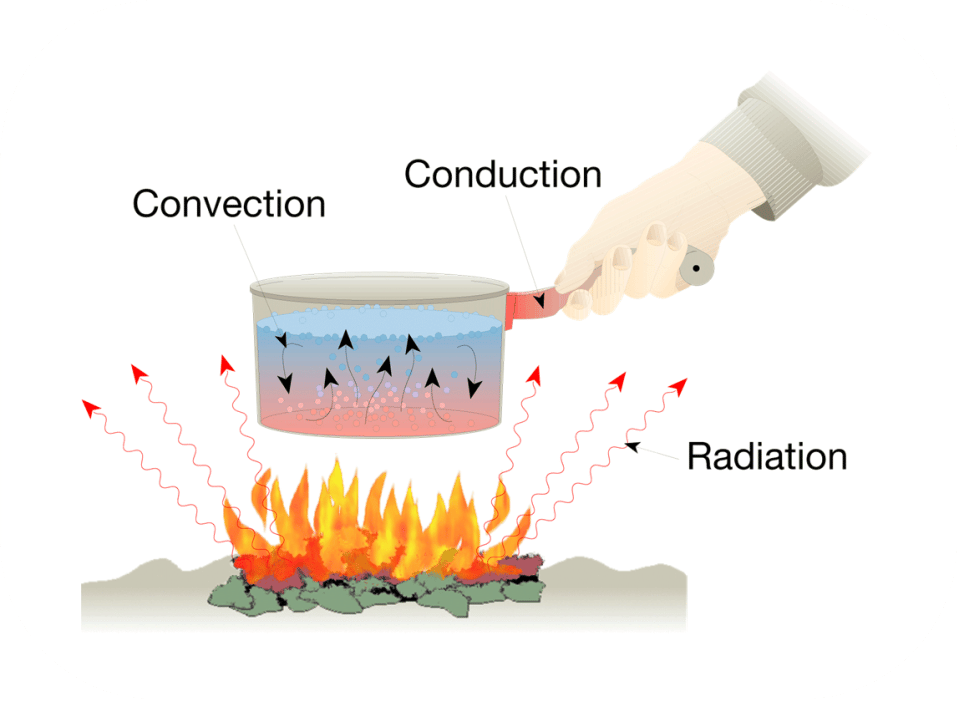

U-values are expressed in units of W/m²K; the lower this value is, the better insulated the building is. Therefore, with better insulation comes better thermal efficiency and retention, leading to lower bills. Building regulations and standards dictate that the U-value of new builds and retrofits should be 0.3W/m²K. U-value includes the three major ways in which heat loss occurs – conduction, convection, and radiation.

Conduction is the process by which heat energy is transmitted through molecules. Convection is the process by which heat is transferred by the movement of a heated fluid like air or water. Radiation does not require a medium for transmission as it moves via electromagnetic waves. For example, let us take a pot of water above a flame. Firstly, conduction would take place through the handle towards your hand. Secondly, convection occurs within the pan as the warmer water cycles inside to transfer heat energy. Lastly, radiation is emitted directly from the flame and dissipates into the surrounding environment.

What are R-values?

The R-value is a value that indicates how good a material is at resisting the flow of heat. Therefore, a higher R-value in insulation materials translates to better thermal performance. R-values tend to form the first step when you consider investing in insulation, as it is easier to calculate than the U-value. However, it only considers conduction as the form of heat energy transfer.

Several factors affect the R-value; it is also determined by the material, thickness, and density of the product. Unlike thermal conductivity, thermal resistance (R-values) solely depends on the material’s thickness. Thicker insulation has a higher thermal resistance and lower thermal conductivity.

What is a lambda value?

Lambda value or K-value may seem identical to the U-value in that it concerns a product’s thermal conductivity. However, the lambda value is specific to the material in question, whereas the U-value is concerned with the thermal conductivity of the whole construction. The lambda value is represented by the Greek letter ‘λ’ and is used throughout the industry in thermal calculations. The lower the lambda value of the insulating material, the better the insulation efficiency will be. In practical terms, it represents the amount of energy that can penetrate 1 metre of the material if the temperature difference is 1 degree.

Putting it all together – R-values into U-values

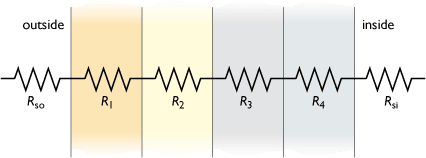

The exercise aims to determine the U-value and begins with examining the lambda value of each material layer used. The whole construction will have several layers, including internal plaster, brickwork, basecoats, adhesives, insulation, and render. All of these impact the U-value as they all possess independent R-values; moreover, there is a thin film of air on either side of the envelope that acts as an insulant. The layers of air are indicated by the Rso and Rsi labels bracketing the physical materials in the construction. The thin layers have values of 0.06W/m²K and 0.12W/m²K for the internal and external surfaces, respectively.

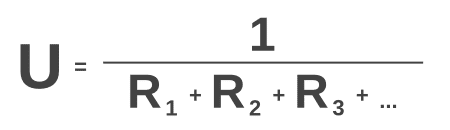

The first step is to determine the R-value of each of the layers. To resolve this, divide the material thickness by the lambda value.

Once the R values are established, they can be plugged into the following equation to determine the U-value. The R-values then need combining to determine the R-value of the entire construction. At this stage, you should incorporate external walls, floors, the roof, windows, doors, and the rest of the building assembly. Dividing 1 by the combined R-value will result in the U-value. The values are the inverse of each other, as a higher R-value results in a lower U-value, and in that, they combine to reduce the heat loss of the property. They are also inverse because the below calculation can be reversed; to calculate the R-value, divide 1 by the U-value.

Insulation, U-values, and R-values

Insulation will add another layer to the overall assembly. External wall insulation boards will come with their own R-value which will contribute to the overall lowering of the U-value. The thickness will inevitably play a part in how much insulation is installed, as different forms of insulation require different thicknesses to achieve a U-value of 0.3W/m²K.

At EWI Store, we stock three different forms of insulation boards, which all carry different thermal conductivity and R-values:

| Thermal conductivity | R-value | |

| Mineral Wool | 0.036W/(m2K) | 1.39W/(m2K) |

| EPS | 0.032W/(m2K) | 1.97W/(m2K) |

| Kingspan K5 | 0.021W/(m2K) | 2.5W/(m2K) |

Based on the figures above, we have determined the thickness required to achieve the final U-value of 0.3W/m²K. However, this can vary depending on the substrate you are using, as cavity walls or ICF builds will have different starting values. Most assemblies will also have varied layers to them, all with separate R-values. Despite this, we recommend the following: Mineral Wool at 110mm, EPS at 90mm, and Kingspan K5 at 60mm. The products also hold other benefits that extend beyond thermal insulation.

Mineral Wool – Dual density composition provides a strong and sturdy base for the render finish, whilst the open porous structure traps sound waves to provide acoustic insulation for the property. Mineral Wool also has a fire rating of A1, actively acting as a fire break feature in buildings.

EPS – A cost-effective solution that does not sacrifice thermal performance. EPS boards are also extremely light, easy to handle, and easy to cut with the EWI Store range of EPS wire cutters.

Kingspan K5 – Premier space-saving insulation boards of phenolic composition. Also possesses extra resistance to mechanical impact due to higher compressive strength.

Finally, if you have any other questions about U-values & R-values, leave us a comment below.

Facebook

Twitter

LinkedIn

Your cart

Trade Account Login

We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. By clicking “Accept All”, you consent to the use of ALL the cookies. However, you may visit "Cookie Settings" to provide personalised consent.

Manage consent

Privacy Overview

This website uses cookies to improve your experience while you navigate through the website. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. We also use third-party cookies that help us analyze and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may affect your browsing experience.

Necessary cookies are absolutely essential for the website to function properly. These cookies ensure basic functionalities and security features of the website, anonymously.

| Cookie | Duration | Description |

|---|---|---|

| __stripe_mid | 1 year | This cookie is set by Stripe payment gateway. This cookie is used to enable payment on the website without storing any patment information on a server. |

| __stripe_sid | 30 minutes | This cookie is set by Stripe payment gateway. This cookie is used to enable payment on the website without storing any patment information on a server. |

| _GRECAPTCHA | 5 months 27 days | This cookie is set by the Google recaptcha service to identify bots to protect the website against malicious spam attacks. |

| apbct_cookies_test | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_page_hits | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_prev_referer | session | Functional cookie placed by CleanTalk Spam Protect to store referring IDs and prevent unauthorized spam from being sent from the website. |

| apbct_site_landing_ts | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_site_referer | 3 days | This cookie is placed by CleanTalk Spam Protect to prevent spam and to store the referrer page address which led the user to the website. |

| apbct_timestamp | session | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| apbct_urls | 3 days | This cookie is placed by CleanTalk Spam Protect to prevent spam and to store the addresses (urls) visited on the website. |

| AWSALBCORS | 7 days | This cookie is managed by Amazon Web Services and is used for load balancing. |

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| ct_checkjs | session | CleanTalk–Used to prevent spam on our comments and forms and acts as a complete anti-spam solution and firewall for this site. |

| ct_fkp_timestamp | session | CleanTalk sets this cookie to prevent spam on the site's comments/forms, and to act as a complete anti-spam solution and firewall for the site. |

| ct_pointer_data | session | CleanTalk sets this cookie to prevent spam on the site's comments/forms, and to act as a complete anti-spam solution and firewall for the site. |

| ct_ps_timestamp | session | CleanTalk sets this cookie to prevent spam on the site's comments/forms, and to act as a complete anti-spam solution and firewall for the site. |

| ct_sfw_pass_key | 1 month | CleanTalk sets this cookie to prevent spam on comments and forms and act as a complete anti-spam solution and firewall for the site. |

| ct_timezone | session | CleanTalk–Used to prevent spam on our comments and forms and acts as a complete anti-spam solution and firewall for this site. |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features.

| Cookie | Duration | Description |

|---|---|---|

| __zlcmid | 1 year | This cookie is used by Zendesk live chat and is used to store the live chat ID. |

| bcookie | 2 years | LinkedIn sets this cookie from LinkedIn share buttons and ad tags to recognize browser ID. |

| bscookie | 2 years | LinkedIn sets this cookie to store performed actions on the website. |

| lang | session | LinkedIn sets this cookie to remember a user's language setting. |

| lidc | 1 day | LinkedIn sets the lidc cookie to facilitate data center selection. |

| UserMatchHistory | 1 month | LinkedIn sets this cookie for LinkedIn Ads ID syncing. |

Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.

| Cookie | Duration | Description |

|---|---|---|

| __utma | 2 years | This cookie is set by Google Analytics and is used to distinguish users and sessions. The cookie is created when the JavaScript library executes and there are no existing __utma cookies. The cookie is updated every time data is sent to Google Analytics. |

| __utmb | 30 minutes | Google Analytics sets this cookie, to determine new sessions/visits. __utmb cookie is created when the JavaScript library executes and there are no existing __utma cookies. It is updated every time data is sent to Google Analytics. |

| __utmc | session | The cookie is set by Google Analytics and is deleted when the user closes the browser. It is used to enable interoperability with urchin.js, which is an older version of Google Analytics and is used in conjunction with the __utmb cookie to determine new sessions/visits. |

| __utmt | 10 minutes | Google Analytics sets this cookie to inhibit request rate. |

| __utmv | 2 years | The __utmv cookie is set on the user's device, to enable Google Analytics to classify the visitor. |

| __utmz | 6 months | Google Analytics sets this cookie to store the traffic source or campaign by which the visitor reached the site. |

| sib_cuid | 6 months | Purechat uses this cookie to send data to purechat.com, to connect visitors to the reservation team and track visitors to stay on portal. |

| SRM_B | 1 year 24 days | Used by Microsoft Advertising as a unique ID for visitors. |

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc.

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _gat_gtag_UA_61069204_2 | 1 minute | Set by Google to distinguish users. |

| _gat_UA-61069204-2 | 1 minute | A variation of the _gat cookie set by Google Analytics and Google Tag Manager to allow website owners to track visitor behaviour and measure site performance. The pattern element in the name contains the unique identity number of the account or website it relates to. |

| _gcl_au | 3 months | Provided by Google Tag Manager to experiment advertisement efficiency of websites using their services. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| _uetsid | 1 day | This cookies are used to collect analytical information about how visitors use the website. This information is used to compile report and improve site. |

| CONSENT | 2 years | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. These cookies track visitors across websites and collect information to provide customized ads.

| Cookie | Duration | Description |

|---|---|---|

| _fbp | 3 months | This cookie is set by Facebook to display advertisements when either on Facebook or on a digital platform powered by Facebook advertising, after visiting the website. |

| ANONCHK | 10 minutes | The ANONCHK cookie, set by Bing, is used to store a user's session ID and also verify the clicks from ads on the Bing search engine. The cookie helps in reporting and personalization as well. |

| fr | 3 months | Facebook sets this cookie to show relevant advertisements to users by tracking user behaviour across the web, on sites that have Facebook pixel or Facebook social plugin. |

| MUID | 1 year 24 days | Bing sets this cookie to recognize unique web browsers visiting Microsoft sites. This cookie is used for advertising, site analytics, and other operations. |

| NID | 6 months | NID cookie, set by Google, is used for advertising purposes; to limit the number of times the user sees an ad, to mute unwanted ads, and to measure the effectiveness of ads. |

| test_cookie | 15 minutes | The test_cookie is set by doubleclick.net and is used to determine if the user's browser supports cookies. |

| uuid | 6 months | MediaMath sets this cookie to avoid the same ads from being shown repeatedly and for relevant advertising. |

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt-remote-device-id | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt.innertube::nextId | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |

| yt.innertube::requests | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |

Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet.

| Cookie | Duration | Description |

|---|---|---|

| _clck | 1 year | No description |

| _clsk | 1 day | No description |

| _uetvid | 1 year 24 days | No description available. |

| AnalyticsSyncHistory | 1 month | No description |

| apbct_pixel_url | session | No description |

| apbct_visible_fields_0 | session | No description |

| apbct_visible_fields_1 | session | No description |

| apbct_visible_fields_10 | session | No description |

| apbct_visible_fields_2 | session | No description |

| apbct_visible_fields_3 | session | No description |

| apbct_visible_fields_4 | session | No description |

| apbct_visible_fields_5 | session | No description |

| apbct_visible_fields_6 | session | No description |

| apbct_visible_fields_7 | session | No description |

| apbct_visible_fields_8 | session | No description |

| apbct_visible_fields_9 | session | No description |

| ct_checked_emails | session | No description |

| ct_has_scrolled | session | No description |

| ct_mouse_moved | session | No description |

| ct_screen_info | session | No description |

| ictf_master | never | No description available. |

| li_gc | 2 years | No description |

| m | 2 years | No description available. |

| SM | session | No description available. |

| testinfinitycookie | session | No description |

| woocommerce_show_tax | 7 days | No description available. |

| wp_woocommerce_session_c5ac76b408021294cb56bcc27eddf8a1 | 2 days | No description |