EWI-240 EPS Adhesive 750ml

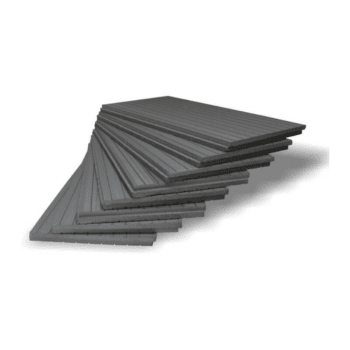

EWI-240 EPS Adhesive 750ml is a one-component-low-pressure Polyurethane Graphite Adhesive PPU-2, designed for fixing XPS and graphite EPS boards for the insulation of facades and foundations.

Properties

- Easy and convenient to use

- For bonding insulation boards on facades and foundations enables anchoring 2 hours after application, full curing 24 hours after application

- Very good adhesion to bitumen and any mineral substrates

- Excellent adhesion to concrete, mineral, ceramic, plaster, etc.

- Works in a wide temperature range

Intended Uses

EPS Adhesive is used for bonding graphite Styrofoam boards on facade installations for thermal insulation of external walls, polystyrene panels, wall panels, installation of windows sills, and filling gaps in the insulation. Additionally, EPS Adhesive is also used for bonding Styrofoam boards for insulation on building foundations using extruded polystyrene (XPS).

EPS Adhesive has excellent adhesion to concrete, ceramic, wood, PVC, and all types of Styrofoam and plasters. Please allow up to 2 hours after applying EPS Adhesive before continuing work. The boards should then be polished with abrasive paper and additional mechanical fixings. The total curing time is 24 hours.

Application

Surfaces must be free of dust, debris, and other materials that would impair the bond strength. Check the adhesion of the existing paint or plaster, as you must remove any old layers. Before using, ensure the can temperature is above zero (optimum +20°C). Shake the can vigorously for 30 seconds to mix the components. Screw the gun on the can. Hold the can upside-down during application.

Fixing graphite expanded polystyrene boards (EPS) on facade installations

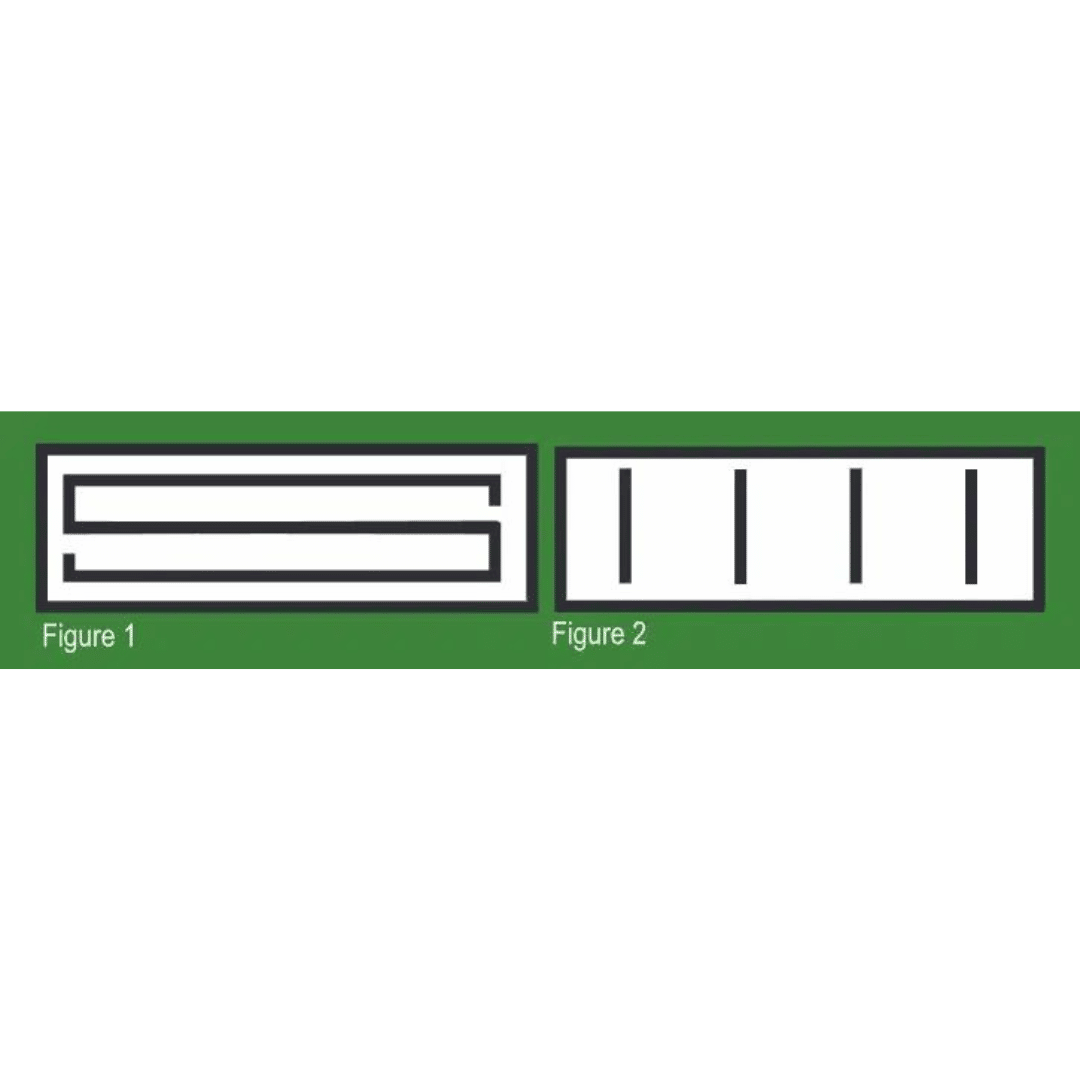

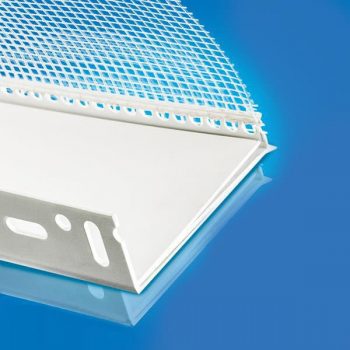

Before adhering the polystyrene board to the substrate, you must install a starter track. For foamed polystyrene facade insulation adhesion, apply a bead of EPS Adhesive (approx. 3cm wide) around the perimeter of polystyrene boards (approx. 2cm from the edge), with an additional bead across the centre of the board. Make about 5cm breaks in strings, as shown in Figure 1.

Join the board with the wall right after the product application (up to 3 mins), press slightly, and adjust using a long straightedge. The board position can be corrected (without removing it from the bonding surface) within 4 minutes of joining it to the wall. In the case of detachment from the surface, apply EPS Adhesive again. At lintels and corners, support the boards until the bond cures.

After 2 hours, the boards should be polished with abrasive paper and fixed with special mechanical fixings. Fill the gaps between boards using EPS Adhesive.

Fixing of Thermo-Insulation to Foundation

Before bonding the boards at low temperatures, remove the frost from the surface. In the case of substrates coated with bitumen, check the adhesion. The base bitumen must be seasoned and well-connected, and any moisture should be evaporated entirely.

For adhesion of extruded polystyrene foam XPS on foundations, apply EPS Adhesive in 4 vertical beads (shown in Figure 2) approx. 3cm wide, maintaining an equal spacing of 20-30cm. Ensure 3cm clearance from the board’s edge (for boards wider than 100cm, you should apply more bead braids). Join the board with the wall right after the product application (up to 3min.), press slightly, and adjust using a long straightedge.

The board position can be corrected (without removing from the bonding surface) within 4 minutes of joining it to the wall. In the case of detachment from the surface, apply EPS Adhesive again. At lintels and corners, support the boards until the bond cures.

After 2 hours, the boards are ready for further processing. Additional mechanical fixings are required in the plinth area and along the edge of the building. Fill the gaps between boards using EPS Adhesive.

Technical Data

- Working and substrate temperature from -5°C to +30°C.

- Can temperature: +20°C

- Correction time about 4min (at +25°C / RH 50%)

- Fixing time about 2 hours

- Adhesive coverage (for Foundation) up to 12 m². Efficiency depends on air humidity and temperature.

- Package efficiency (for ETICS) the surface of up to 8 m² (seamless thermal insulation system) the efficiency depends on the air temperature and humidity.

- Shelf Life: 12 months

- Validity date and lot number are printed on the package

Storage Conditions

- Keep in an upright position.

- Store in temperatures between +5°C to +30°C (room temperature is recommended).

- Keep in a dry, cool, and well-ventilated place away from direct sunlight, other heat sources, and ignition. (Storing the product in conditions other than the recommended may shorten the lifetime by three months.)

- The expiration date is located on the packaging.

Does not include a Foam Applicator Gun, you can purchase one here.

Frequently Asked Questions

- What do I need to be able to apply the foam?

To apply the foam, you will need a Foam Applicator Gun, which can be purchased from us.

- How long does it take for EPS Adhesive to dry?

EPS Adhesive enables anchoring 2 hours after application and full curing 24 hours after application. After 2 hours, the boards should be polished with abrasive paper and fixed with special mechanical fixings. Additionally, you should fill in the gaps between boards using EPS Adhesive.

- How much correction time do I have if I make a mistake?

When applying EPS Adhesive, you will have approximately 4 minutes at +25°C / Relative Humidity of 50%) to correct the positioning of the EPS boards without detaching the board from the surface if you make a mistake. In the case of detachment, reapply EPS Adhesive.

- Do I need mechanical fixings if I use EPS Adhesive?

Yes, after 2 hours, the boards should be polished with abrasive paper and fixed with special mechanical fixings and are required in the plinth area and along the edge of the building.

- What temperatures can I use EPS Adhesive in?

Although room temperature is recommended, you can use EPS Adhesive in a temperature range of +5°C to +30°C. Additionally, the can should be at a temperature of +20°C.

Reviews

There are no reviews yet.