Performance Basecoat (EWI-222P) – 25kg

£14.99 Excl. VAT

- Long-term protection & low maintenance

- Highly vapour permeable

- Low-temperature application

- High adhesion

Disclaimer: This basecoat is used in render-only projects and can be used to fix EPS Insulation boards.

999 in stock

EWI-222P Performance Basecoat 25kg

EWI-222P Performance Basecoat 25kg is a polymer-rich cementitious basecoat that can be used on many different substrates, providing a breathable and water repellent protective coat. You can use EWI-222P on render-only projects as well as to fix EPS Insulation boards (where it can be used as an adhesive and a basecoat). EWI-222P should always be finished with a Silicone Render to ensure a robust and long-lasting decorative finish.

For use in render-only projects as well as to fix EPS Insulation boards (Basecoat/Adhesive), do not use for other Insulation board types.

Substrate Preparation

All surfaces should be clean, dry and free from any material which may impair adhesion. Scaffolding must be independently tied to allow for uninterrupted application. Any faults in the structure, particularly those that may lead to moisture penetration must be rectified, potentially using EWI-260 Levelling Mortar. Mask around the areas where the material is to be applied. Masking tape must be removed before the material has dried out. Beads and expansion joints should be included as required by both the substrate and British Standards and carried through all applied materials. Do not apply to shiny surfaces.

Product Preparation

EWI-222P Performance Basecoat should be mixed with clean water at a rate of approximately 4.5-5 litres per 25kg bag using a suitable paddle or pan mixer. Mix the product for 2 minutes, and allow it to stand for 2 mins and then re-mix. This process allows the additives to dissolve and activate.

NOTE: EWI-222P Performance Basecoat may stiffen on standing. Re-mix the product to regain a workable consistency – but do not add any more water.

Application

When applying to concrete block, clay, lightweight block or brick; prime the surface with EWI-310 Universal Primer. To avoid dampness and discolouration, the basecoat should not be below the DPC or within 150mm of ground level.

The first pass should be applied to the primed substrate with a stainless steel trowel or spray pump, to a depth of 3-4mm (insulated substrate) and 5mm (masonry substrate). Fibreglass mesh should be embedded within the first pass and ensure that the mesh is overlapped 100mm at the mesh joints. Additional fibre-reinforcing mesh stress patches of 500 x 500mm should be added for additional substrate stress protection.

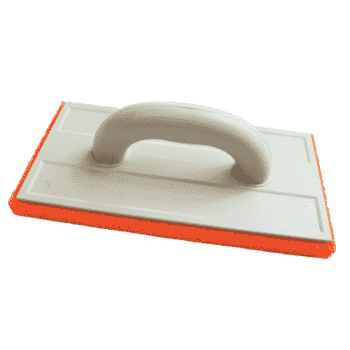

The second pass should then be applied to approx. 3mm thick (insulated substrate) or 5mm (masonry substrate). The basecoat should be finished off with a notched trowel or sponge float depending on the selected finish.

When using EWI Pro Performance Basecoat as a bedding adhesive for insulation, apply the adhesive to the back of the insulation board using an appropriate trowel. For uneven substrates, we recommend applying the adhesive to the perimeter of the insulation board with 3 additional dabs across the middle of the board. For flat substrates, you can apply the adhesive to the entirety of the insulation board using a notched trowel.

The total thickness of the performance basecoat should be 6mm (insulated substrate) or 10mm (masonry substrate)

Application Conditions

Weather Conditions for application and drying are critical.

- Do not apply if frost is forecast within 24 hours, in wet conditions or when the humidity is above 95% or in temperatures below 3°C or above 25°C.

- Weather conditions must be as specified above both during application and for a minimum of 24 hours after application.

- Do not apply to elevations which are hot or below 3°C and or in direct sunlight.

- The render must be protected against heavy rain, direct sun and wind in the first 24 hours after application. (Sheeting the façade or the scaffold is advised to protect against this.)

Technical Specifications

- Composition: Portland cement, Hydrated Lime, polymers, modifying admixtures.

- Dry bulk density, 1690 kg/m3

- Capillary water absorption, W2

- Reaction to fire, F

- Water vapour permeability coefficient, μ ≤ 15/35

- Compressive strength, CS IV

- Thermal Conductivity, (λ10, dry) 0.61 W/mK (tab. mean value; P = 50%)

- Adhesion, ≥ 1.0 N/mm2, (FP) B

Safety Measures

You must wear protective goggles, gloves, respiratory equipment and protective clothing when mixing and using this product. Avoid contact with the eyes. In the event of eye contact, wash the affected area with plenty of cold water as soon as possible and seek medical attention. Do not ingest. Keep out of reach of children. Refer to material safety sheet for further information regarding first aid and protection recommendations. Contact with wet cement may cause irritation, dermatitis or burns. For further details, refer to our Health & Safety Data Sheets.

Contains Portland Cement and Hydrated Lime.

Storage Conditions & Tool Cleaning

When stored unopened in a dry place, at temperatures above 5°C, shelf life is 12 months from date of manufacture.

All equipment must be washed with clean water immediately after use. Waste material should not be emptied into drainage systems.

Coverage

This bag will cover approximately 1m2 when applied to a thickness of 15mm.

Note: This estimate takes no account of wastage or uneven surfaces

Frequently Asked Questions

- What is the difference between 222P and 225?

The main difference between EWI-222P and EWI-225 is that Performance Basecoat is only suitable for render-only applications and fixing EPS boards to substrates. Alternatively, Premium Basecoat is suitable for all applications, including render-only and external wall insulation projects.

- Can 222P be applied using a spray machine?

Yes, Performance Basecoat can be applied using a spray machine (Tested with the Euromair DropPro 8P and Mixpro 28) or by hand using a trowel.

- Can I use 222P as an adhesive?

You can use Performance Basecoat as a base for reinforcement layers on render-only projects and different insulation materials, including EPS.

- How much water do I need to mix with 222P?

Using a suitable paddle or pan mixer, you should mix approximately 4.5-5 litres of water per 25kg bag of 222P. Mix the product for 2 minutes, allow it to stand for 2 mins, and then re-mix. This process allows the additives to dissolve and activate. Performance Basecoat may stiffen on standing. Re-mix the product to regain a workable consistency – but do not add more water.

- What should the total thickness of 222P be?

The total thickness of the performance basecoat should be 6mm (insulated substrate) or 10mm (masonry substrate).

| Weight | 25 kg |

|---|

Pete Tunwig –

Won’t go back to any other basecoat after using this!

Originally purchased the Premium Basecoat but heard good things about this from another plasterer, and it really is ‘performance’ heavy! Every project I’ve used this on just looks great!

Casper888 –

Rubs up decent, like johnstones performance basecoat.