Tanking Systems

Log in to save items on your shopping lists and access them on all your devices. Guest lists are deleted after 90 days.

Our tanking systems provide effective waterproofing solutions for basements, cellars and below-ground spaces. Designed to control water ingress, manage hydrostatic pressure and prevent moisture penetration, these systems help turn damp, unusable areas into dry, habitable spaces with long-term, reliable protection.

What is a tanking system?

A tanking system is a waterproofing system used to protect existing structures against damp, moisture and water damage. It works by creating a sealed barrier or drained protection layer that blocks or redirects water before it reaches internal finishes. Tanking is commonly used in basement tanking, cellar upgrades and areas below ground level.

How it works in basement waterproofing

In basement waterproofing, tanking systems resist water pressure from surrounding soil and groundwater. Water can enter through cracks, capillary action, or defects caused by structural issues and building faults. A correctly installed tanking or cavity drain system prevents penetrating damp and allows moisture to be controlled without damaging internal finishes.

Types of tanking and cavity drain systems

We supply two main types of basement tanking systems depending on your project, substrate and water exposure levels.

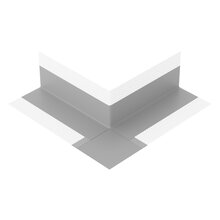

Tanking membranes and damp proof membranes

Tanking membranes and damp proof membranes form a watertight barrier directly on tanking walls and floors. These systems are ideal for problems linked to rising damp, damp walls and damp patches caused by capillary action or external water sources.

- Create a continuous waterproofing membrane

- Resist hydrostatic pressure

- Used on walls and floor slab areas

- Suitable for returns, corners and plasterboard interfaces

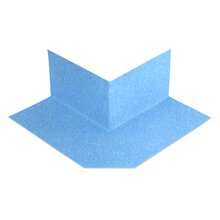

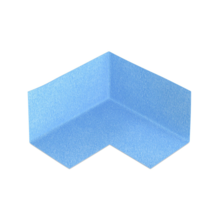

Cavity drain membranes and sump pumps

Cavity drain membranes form part of advanced cavity drainage systems designed to manage water rather than block it. Water is channelled behind the membrane and guided to drainage channels, perimeter drainage channels and into sump pumps before being safely discharged.

- Uses polypropylene mesh membranes to create an air gap

- Relieves pressure on the structure by managing direct water

- Prevents moisture build-up behind finished surfaces

- Ideal for earth retaining walls and high water table areas

Benefits of using tanking systems

- Prevents penetrating damp and rising damp

- Provides long-term reliable protection against water ingress

- Converts damp basements into dry habitable space

- Protects against moisture-related building faults

- Improves thermal and comfort performance in below-ground structures

Protection against rising and penetrating damp

Tanking systems stop water movement caused by capillary action, damaged drain routes, poor drainage or surface runoff. This is particularly important when dealing with older buildings, lime build properties, or projects involving structural refurbishment below ground level.

Is tanking a good idea for basements?

Yes. A properly designed tanking or cavity drain system is an essential solution for turning a damp cellar or basement into usable space for storage, utilities or full basement conversion.

Longevity and compliance with British Standard

Our systems follow modern British Standard guidelines for waterproofing and below-ground construction. When installed correctly, they offer long-term durability and performance, supporting both refurbishment and new-build structures.

Our range of tanking and cavity drain systems

We supply a full range of tanking and cavity drain systems, including:

- Tanking membranes and slurries for walls and floors

- Cavity drain membrane systems with drainage channels

- Sump pumps and pump chambers in various sizes

- Accessories and fixings for full installation

All systems are suitable for professional contractors and renovation projects dealing with structural issues, water penetration or long-term moisture control. Browse our full range below, add products to your basket and benefit from fast UK delivery.

If you need technical or expert advice on choosing the right solution for your substrate, structure or application, contact our team for further information and guidance tailored to your build.