Rate & Review

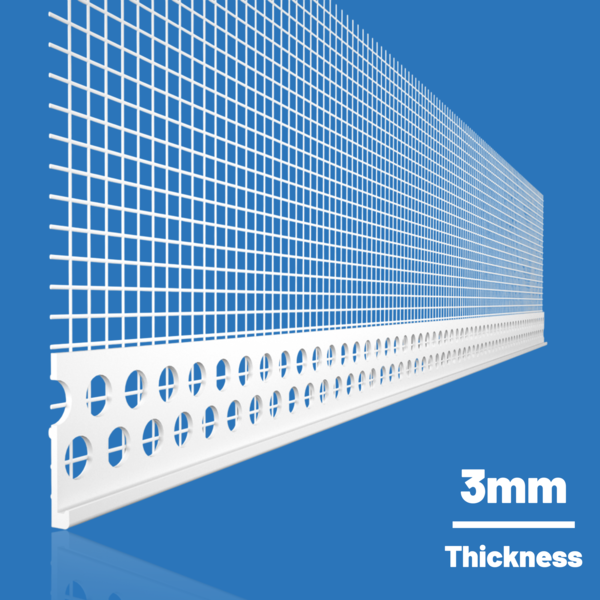

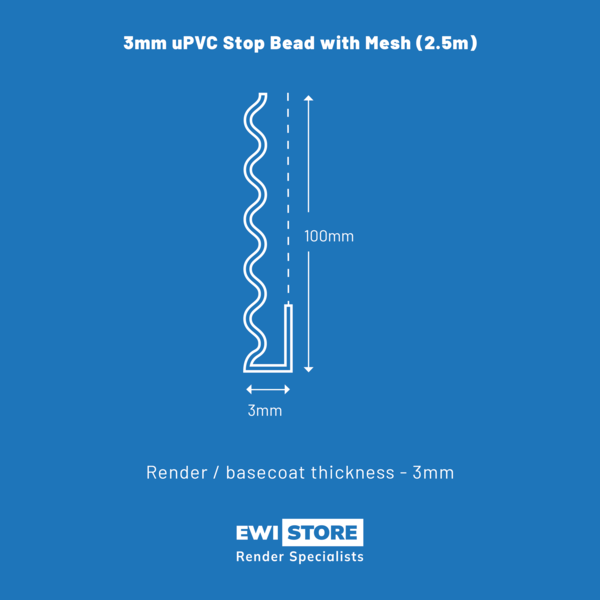

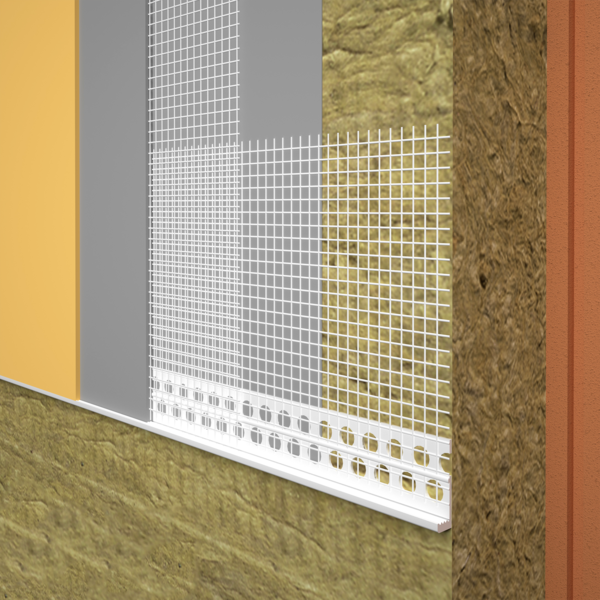

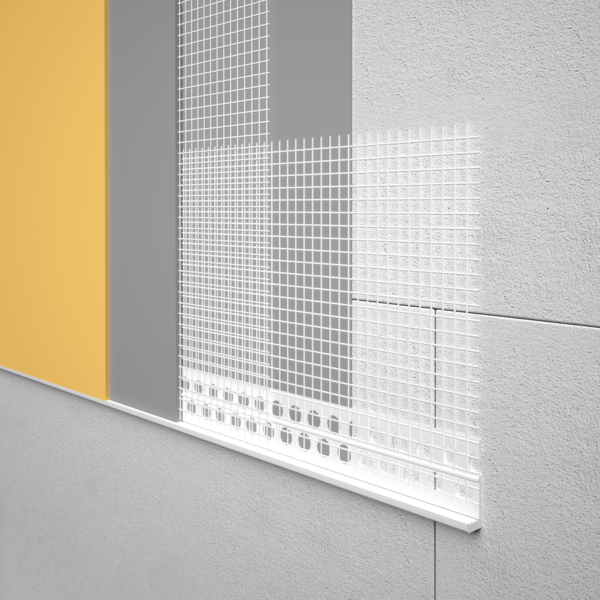

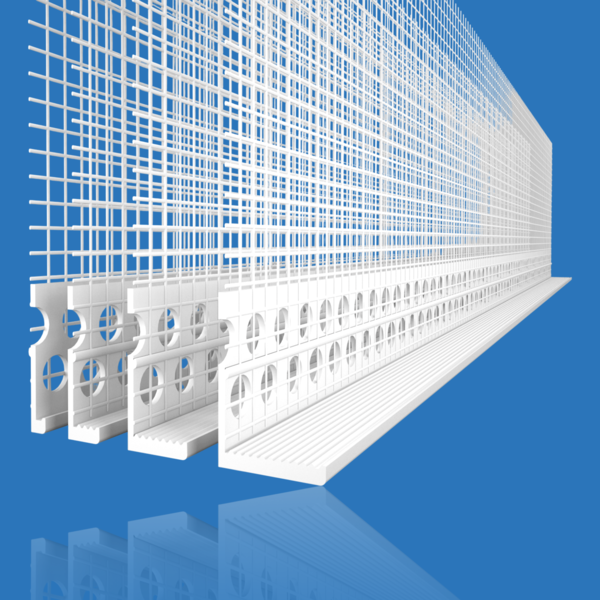

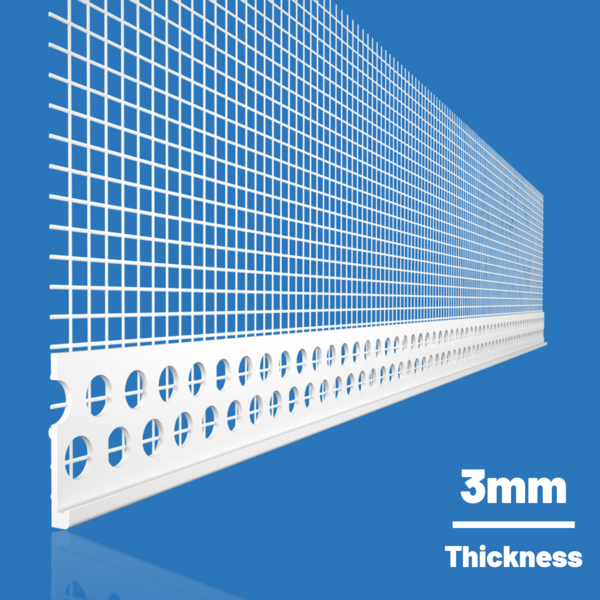

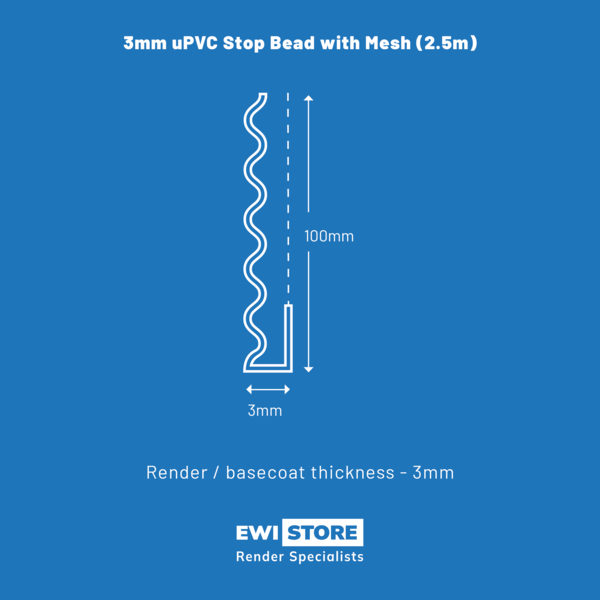

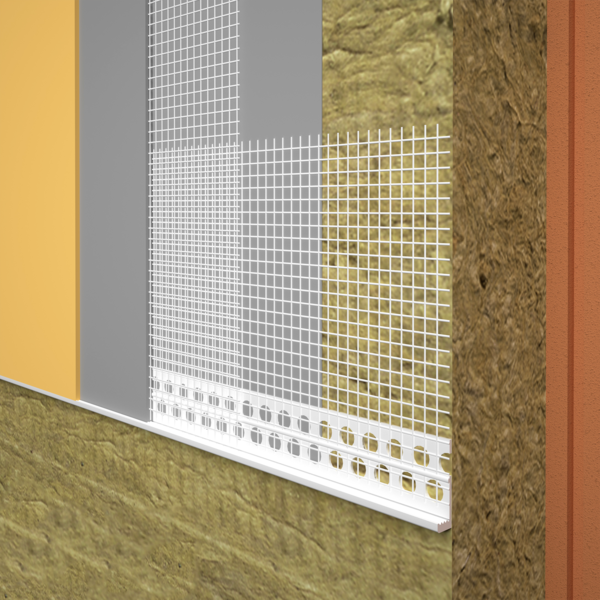

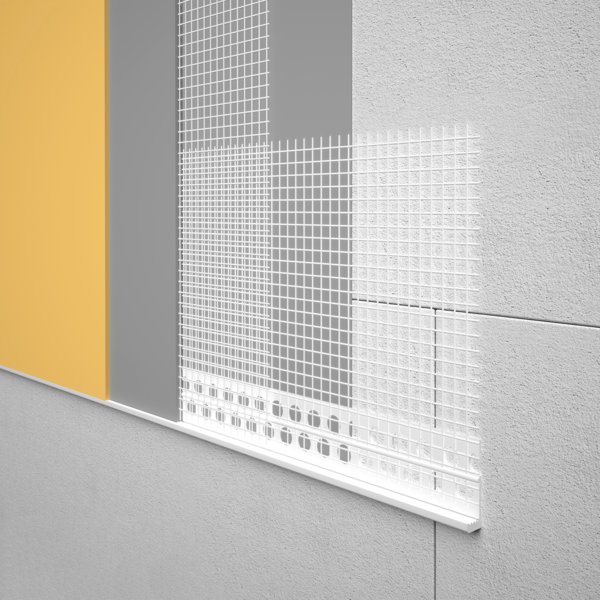

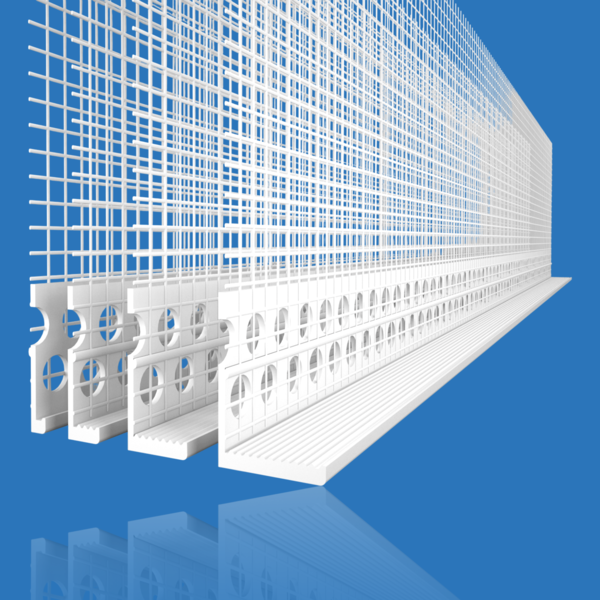

uPVC Stop Bead with Mesh (2.5m)

SKU: LIK-121.0325

Reviews & Ratings

Decent utility bead, achieved the professional straight lines we needed. Was less rigid than my previous brand though, and a bit harder to get a clean cut. Mesh needed a touch more adh than usual to properly secure. For the competitive price, it gets the job done and is good value.

mint edges every time. Mesh integrates perfect. Top kit.

Top quality bead. No warping.

top bead. Straight lengths arrived. Means zero wasts an great finish.

Proper kit. No warping like the cheaper stuf, saved me fighting the corners all afternoon.

This uPVC xstop bead sorted the 10mm depth perfect. Gives crisp lines easily, superior to those metal alternatives. Saved time. Sound.

Sound bead for the price point. Worked fine for my 6mm system, but it's a bit too flexible if you apply a heavier basecoat. Delivery arrived exactly when needed, so saved a faff on site. Good stuff.

⭐⭐⭐⭐⭐Proper job. Straight linew. This PVC stuff is decent and won't snap when you tap it in. Integrated mesh wing is a massive time saver, keeps the job sorted and clean. Good value.

straightened up weao corners perfectly, gives a perfectly crisp reveal. Saves time and proper value kit.

Cracking bit of kit this is. The mesh integrated into the bead is a proper time saver—means no faffing about laying fabric on the basecoat. Used it with a 10mm system and it sat perfectly flush allowing for sharp clean edges exactly as needed. Arrived dead straight with no warping which is a massive plus when you're on a tight run. Solid uPVC too, felt really durable, and no chance of staining like the old metal gear. Easy installation, highly recommended. Proper five stars.

Top quality. Sorted the job.

Proper job for EWI, the finish is dead straight and strong. Good key. Price is a bit steep compared to alternatives, but reliable.

Brilliant. Nailed the sharp reveal edge; saved labour time easily. Mesh was sound. Lacked rigidity compared to aluminium

—needed constant bracing. Price is fair considering the spec. Will be ordering more.

Right piece of kit. Excellent value, mate.

Decent kit, maintained a straight line way better than the other mob I used. Great rigidity, easy fix. Only drama was one bead arrived slightly curved; had a faff getting that true. Brill stuff though.

Solid bead for 6mm. Sharp edges sorted. Just too flimsy when fixing & needs a 3m option to cut down on joints. Price is okay.

Average stuff. uPVC felt brittle and short when measured. Had to trim the plastic flashing

Good kit solid value for money

Used this bead for a 6mm scratch render job. The lines came out proper sharp sorted. Mesh wing keyed into the basecoat mix soundly—stuck right on. It was easy enough to cut the plastic body but trimming where the mesh meets the plastic was harder work than it should be; had to be careful with the stanley knife.

Big selling point is the flexibility, though. Being able to cover 3mm all the way up to 15mm systems is a massive saver on site—don't have to carry different bead gauges for different jobs. Top flexibility, really appreciated that bit of clever design.

Only losing a star because one of the lengths had a noticeable crease in it on arrival. Had to trim the damaged section out which cost time and material. Packaging could be more robust to avoid that, but otherwise, job's a good 'un.

Proper gear this. The mesh integration is brilliant, means it beds in quick, gave a cracking clean edge for the 10mm render. Sorted. Top qualoity.

This bead gives a proper sharp finish. Much better than the brittle rubbish used before. 2.5m lengths meant hardly any joins. Massive time saver, dead easy to fit.

Solid stop bead. Runs dead straight and gave a sharp line, much better than fighting metal. Used it on a 10mm system� it� s quality kit. Well worth the price.

Much better than metal beads. STRAIGHT lines every time and flexible. Top kit.

Sorted! Easy install nice sharp lines and priced right compared to the others. Brill.

Finally a straight bead! Bob on clean lines.

Nearly Perfect Bit Of Kit

Solid bit of kit. Dead straight line on this for the 10mm system. Provides a sharp finish, simple to score and cut on site. Feels sound.

My only beef is the length. The 2.5m is a right pain on the tricky zreas, I wish they did two-meter sticks for gable ends and fiddly returns to cut down on waste. Also tha big 100mm mesh needed a fair bit of push into the adh to key properly flat. Got one piece with a slightly mashed corner, so a QC niggle there too.

Worth the price for the clean lines, though. Just needs sorting in the warehouse/stocking dept.

It's a good bit of kit uPVC is dead flexible. Made the line sharp on the basecoat. Fair play. But I had one warped one out of the wrap bit of a pain to fight into alignment. Get the QC right EWI.

Top quality bead, went up ded easy. Looks mint on the finish.

Brill finish, quality bead. Gave me the sharp edges needed for the job.

Excellent quality bead for my 10mm system. Fitted a treat and gives clean sharp edges.

absolute urbbish. Not weatherproof at all! Failed straight away during the first light shower. Now the basecoat is compromised. This cheap plastic junk is gnna lead to render failure and I've awasted a whole afternoon pulling it out. Use proper BBA gead instead.

ABSOLUTE rubbish. Every length of stop bead was warped and chipped right out of the delivery box which had NO protection only a thin film. shocking quality for the money. paid £4.30 a stick for material flimsier than Skeels direct stuff. now my job is stalled. straight into the skip, USELESS.

solid PVC stop bed. It cuts super easy, saves time compared to galvanised. Gets the finish spot on. Wish they had a 3m length option available; feels pricey for 2.5m but the quality is sound.

absolute waste of a day waiting for these UPVC stop beads. i was stuck on site all morning waiting and not a soul showed up. not one phone call or text about the no-show either. gutted. cost me a whole morning of work and totally screwed up my render schedul.

Pukka bead got me a dead straight 10mm edge. Needed a specialist mesh gauge which wasn't available, but this one worked acceptably. Driver was proper abrupt, dropping a star for service.

This bead is quality! Made my render job loads faster those 100mm mesh wings save so much time. Very straight lines good value for money.

Look it functions okay but the uPVC colour is a bit creamy�expected whiter. Mesh felt thinner than usual. Snapped unexpectedly cutting a mitre. Too brittle too expensive for average quality gear.

Went up dead straight saved loads of faffing. The mesh tie-in is proper robust. No cracking on site either. Quality job. Fast delivery was a bonus.

Dead easy to use, gives a wicked straight edge. Been looking for a proper decent stop bead for the 10mm system, this one's spot on. Knocking these in was dead easy, saves a load of time. The finish is professional, every single bead stays perfectly true and I got a really sharp, clean line out of it, no wobble at all. The uPVC material is really tough but cuts fine, it didn't snap or feel brittle at all when I was handling the 2.5m lengths. Mesh wings bonded perfect to the basecoat as well. I'm properly chuffed. Found my new standard bead, I won't use anything else now. Highly recommended.

Cracking bit of kit. Easy to fit, finish is clean, edges look spot on.

Cheers EWI! Came fast, gives a sound straight finish on the muck.

Quality stuff straight lines no rust risk. Brill!

Top kit! 100mm mesh sits spot on. Dead straight. Works good, saves toime.

Works well. Clean edge, sturdy uPVC. Pricy!

Mesh is already integrated dead easy to fit. Perfect crisp corners. Sorted.

AMAZING! Proper sharp edge.

Cracking kit, gives a razor-sharp finish. Proper job, dead easy.

Cracking kit. Handled easy, went fast, gave a perfect straight line. Much better quality bead than the rubbish I used before.

spot on finish, proper crisp edges. Miles better than the ally stuff!

"Impact-resitsant" is an absolute lie, this thing snapped in my hands—it's brittle RUBBIXSH! Wqrped and clearly too thin/short (bodge job stock) makign straight lines impossible. Useless on my 15mm coat, zero system integrity. I chuckexd it straight in the skip. A complete joke for £4.08 Inc VAT.

it's nowhere near 2.5m mesh is shredding mate and it bent sitting on site in mild sun. paid extra for 10mm got a load of 3 & 6mm mixed up. Awful, wouldn't use this cheap gear again.

Brill! Solid bead gives sharp linses on 10mm. Five stars for service getting it right first time eventually.

Zero waste on the whole order. That never happens! Perfect straight lines for my 10mm system. Sorte.

brill! Perfect fit for 6mm render basecoat, mesh held strong on the EWI job. Decent value kit. Knocked a star off 'cos the finish wasn't razor-sharp

—edges felt a little soft.

Top quality bead gave rock solid lines, job's a good un.

uPVFC is spot on. Went up dead quick and straight on 10mm render coat. Great stuff!

Great bead, got clean, sharp edges sorted straight away for the 10mm work. Went on easy enough. Took a star off cos the delivery was a day late and the rtacking was poor. Good solid finish though.

Wrong bead depgth sent, massive site delay now. Flimsy PVC anyway and the mesh kept fraying. Don't bother. Go local.

the ordering process was a right SHAMBLES rite from the start and i was charged express delivery for standard service then these useless beads arrive poorly packaged half were snapped or bent the plastic is brittle not impact resistant it kep cracking on sight when applying the material flexes way too much impossible to get a straight edge its ragged finish when it finally bedded and the mesh wings tore away a complete waste of my basecoat time is money and this rubbish cost me too much money for zero quality AVOID!!!

Pukka gear. Sharp edges achieved.

Top quality beads. Will use again!

Proper food uPVC stop bead, came out dead straight. Made the scratch coat job mint. Easy to cut. Will use this again.

Spot on! Dead straight edge. This uPVC is robust, not brittle stuff. Massive plus is the 2.5m length; saved me cutting waste on every single run. Great value. Brill.

Top quality bead, mesh is integrated so the basecoat was quick. Good price for the finish achieved, very sharp and proper solid. Spot on!

Cracking bead dead straight for the 10mm system. Proper clean finish. But too dewr mate. Had one slight chip and delivery was a faff. Good kit price needs adjusting.

Spot on. Great for all render depths, mesh wing tucked right in. Way better than cheap site stuff.

EWI quality is spot on. Holds its line straight cuts easily and gives a proper sharp finish on the 10mm.

Chuffed with this! Holds its line perfectly no signs of warp after weeks. Solid kit.

Proper stiff bead. But no clips!

Brill quality. Proper rigid which sorted the reveal straightness fast. Shame it’s only 2.5m but dead easy on the 10 mil kit.

brilliant product. Installed dead easy, keeps a proper true line. Felt really durable, way better than the cheaper plastic stuff I've seen. That robust 100mm mesh ensures a great reinforced edge. Does the job better than the overly expensive alternatives. Spot on.

Brill mesh key. Straight finish achieved. Awful site guide & slight bow cost a star.

This uPVC is solid not flimsy like others. Holds the line perfect every time and locks the mesh tight. Sorted for my 10mm render. Brill!

decent gear. Better than the metal alternatives. Gave a mint edge detail. One scuff on the mesh dropped a star.

Good kit, mate. Straight edge quality matchs the double the price brands. Mesh embedded well. Proper job!

Brill bead! Install was dead easy and the finish is sharp, price is fair.

driver dumped the rubbish in the rai. this flimsy £4.30 uPVC snapped cleaner than old plasterboard when cutting corner details. shocking value and tatty materal.

Straight bead. Quality PVC, but edge needed trimming.

Spot on finish. Dead easy to install, held sharp lines perfectly. Decent value.

Great Stuff! Brill bead for the 6mm adh system, took the flex in the wall spot on. Quick dispatch was a bonus. Only 4 stars because I lost a bit of length trimming the bent end.

Top Quality. Best bead I've used full stop. Handles 3mm right up to 15mm in one, saves huge time on site. Gives a superb sharp finish, dead easy to work with. Proper value for money. Cheers.

Brill mesh is bonded right in. Saves faffing with tape.

Decent kit better than the last stuff we had. It's a bit flimsier than expected; needed extra faffing to get the alignment plumb and the mesh frays easily when trimming. Good for following contours though. Final finish is clean. Value is alright but I have seen this type of bead cheaper. Driver was brill helped me unload. Sorted.

The driver refudsed to carry it and it was bashed up due to zero packaging. it’s fragile, flexed causing wavy lines, and yellowed already. £5 for this Bodge job material is dqaylight ROBBERY, buy the certified stfuf instead.

Decent finish for the money. Needed a proper fiddle with one corner section to get it dead true. Good trade-off.

Proper bead kit. Didn't warp or chip like the cheaper alternatives. Straight finish, zero hassle.

Easy to fit for 10mm systfem. The bead holds rigid & the edge came out dead square. Proper job saved me loads of time. Worth it.

Best uPVC I've used. Cuts easy. Sharp finish every time.

perfect lines 10mm render job spot on

Amazing! Nice, strong PVC, didnt chip when cutting. Best sharp edges for the render job.

Flimsy plastic. Edges needed filing down proper not professional finish I paid for.

Crisp edges perfect for 10mm EWI. Sorted fast on live chat for sizing query. Top job.

Perfect Cracking bead real time-saver. Brill. Genuinely suprised how straight this uPVC lay out of the box, not warped like them cheap bits you see. Its solid yet flexible, a proper doddle to install on the EWI. That 100mm mesh wing keys right into the basecoat mint, thats the critical difference you dont get with the bargain bin stuff. Saved me serious time getting that clean edge. Proper superb bit of kit for the money.

Ace beads, dead straight.

Great Stuff! Bang on quality and a quick install. Used this for a 10mm render system and it was brill. Dimensions were spot on, cut easy without any cracking, and installation was incredibly straightforward, saved me significant time on the corner detail. The mesh actually beds down flat into the basecoat and creates the sharp, professional line I was after. Quality feels very robyust, been outside a few months and zero yellowing so the UV-resistance is solid. The entire process was flawless too: the spec info online was clear, had my query sorted quickly by support, and the delivery was fast. Driver was dead helpful. Can't fault it, my new go-to render stop. Decent priec for this quality.

Sound as a pound. Really solid uPVC, gave me dead straight lines. Didn't kink once.

Quality uPVC. Gives me dead straight edges every time. Brill!

Sharp lines on the corners, feels like decent uPVC and handles all render depths perfectly. Easy fit. Brill stuff!

Brill finish, easy fit. Bit dear though.

Dead straight & spot on for EWI. Saved a lot of hassle trying to true it up so the project flew by. Top quality.

New go-to bead. Dead straight, makes the job easy.

Great stuff! Came dead straight no bowing. 100mm mesh locked in good, strong PVC. Worth paying for quality, job sorted.

Arrived dead quick! Cuts easy and gives a proper sharp line, solid finish. Top quality bead, beats the cheaper ones.

brittle plastic. Length slightly off + mresh end wasn't flat. OK job

Proper Job! Sound quality and straight lines.

Used this on an EWI detail and it was faultless. Gave an exceptional finish and straight edges. Used it across 6mm and 10mm parts of the job worked bang on every time which is massive value there compared to those depth-specific alternatives.

This bead proved much simpler to work with than others I’ve tried previously. Mesh laid into the basecoat flawlessly and the uPVC is sound very impact resistant. No warping either which is great.

Couldn't fault the delivery either. Long lengths were packed proper securely driver remembered my safe drop-off from the last order spot on. Warehouse dude knows what he's doing. Definitely recommending this specific bead to my colleagues.

Got a clean line with the 6mm mix. Decent price, but really need a 3m length option on the stock.

Perfect fit and straight.

Quality bead; easy fit on the 10mm scratch coat. Delivers sharp lines. Price felt too high.

Spot on for 10mm EWI. Doesn't bend when you cut it and that 100mm mesh keys in dead easy. Proper clean edge.

Brill! Eges are spot on and it went in dead easy.

Proper sorted the EWI corner! Dead easy fit and gives a cracking sharp edge.

Quality uPVC stop bead, proper mesh wing, no cracking. Solid!

Proper sharp finish and dead straight. U-P-V-C cut like butter too. Works perfect for the money. Cheers.

Brill! It holds shape under tension and got a clean finish first time. Time saver!

Great stuff! Installed quick perfect 10mm depth. Got incredibly sharp professional edges that clients loved. Top value.

Top quality, dead easy fit!

Dead easy to cut. Perfect egdes and a solid basecoat mesh tie-in. Brill!

Straight bead, mesh tore easy.

Top quality! Easy run, didn't spring. Proper straight line, mesh is perfect.

fits 10mm render system spot on. Solid uPVC. Would be 5 stars but some beads were bowed/short of 2.5m exactly. Time-wasting on site.

Top stop bead. Flexi enough to avoid twists but rock solid for a clean line. The integrated mesh is flawless and speeds up installation majorly. Decent value.

Great value dead easy to get a sharp clean edge. Chuffed.

Brill! Went in a doddle. Cut clean, lines are spot on. Beast plastic I've used.

Sound kit! Worth the extra quid to get the big 100mm mesh already fitted. Got here fast too. Straight edges perfect! Cheers!

Cracking stop bead. Makes the corners look proper professional. The 100mm mesh wing sits dead right in the basecoat. Works good.

Dead straight. Proper strong stuff held its line when the basecoat adh was going in. Finish looks mint. 2.5m length is handy too, saves running a load of extra joints. Should be 5 stars but packaging needs sorting to protect the ends better—got a slight kink on one length. Will be buying more next job though, quality gear.

decent kit for a proper finish. Dead easy to cut the mesh stuck well and kept the edges true. Consistent quality.

Brill! Mesh fixed proper and cutting was dead easy. Very professional straight finish.

Spot on kit. Gave dead crisp lines and the 100mm mesh stuck well in the basecoat. The uPVC material is far easier to work with.

Better than the rest. Really robust.

Brill, top quality bead. Dead straight line. Sorted.

Ses dead true. Mint for 3mm EWI finish.

Solid uPVC kit. Cuts clean and embeds good in the basecoat for EWI. Gives me proper crisp corners, worth the money. Sorted.

Brill. No bending or scuffing like the cheap sticks. Proper strong and dead straight for the 10mm system. Fitted easily, job sorted.

Dead straight for 10mm basecoat, mesh helped it bond instantly. Flexibility near joins was brill. Will only buy these. Sound.

Perfect straight lines mate. Easy to cut and work with.

Brill!

Excellent finish achieved. The uPVC material is sound and didn't snap during fitting, makes a huge difference to site speed. Got those sharp, clean lines first time. Sorted.

Brill! Stops the faff with separate mesh. The straight line this gives is dead spot on proper crisp edge every time for the EWI. The uPVC material is durable too, won't warp like the cheap rubbish. Huge time saver. Will defo use again. Top quality stuff.

Mesh keeps detaching from the bead. Quaity control is a joke.

Great value stop bead. Easy to work with. Perfect sharp edges, works good.

Spot on quality. Stays dead straight. Better than the usual flimsy stock.

This uPVC bead is proper spot on. Massive upgrade from the cheap metal I used last year. Sorted the edge line. Top value!

Spot on. The uPVC material is proper tough can take a knock. Mesh lays down perfectly, nie sharp edges.

Solid kit. Straight lengths hold true unlike cheaper PVC. 100mm mesh key sinks properly. Keeps the system sound. Just the job.

Did the job. Gives a clean edge but that mesh is a right faff to bend back if you've got even a slight curve. Use it again.

Does the job. Integrated well with the adh straight lines no prob. The plastic is a bit thinner than other makes though and the mesh tore too easily on corners. Good finish overall decent value for money.

Good solid bead for EWI gives cracking lines. Used the 6mm profile on a large run, worked bang on. uPVC is strong took knocks accidentally without snapping, so quality seems proper good, maybe 10% less than true premium stuff but for the price paid, fair value. The 100mm mesh wing bonded into the basecoat OK, its lightweight too so easy transport to site. My main gripe is the spec: the 100mm wing is just a bit fiddly in tight cut-ins on the reveals i think 120mm scrim size (that I see others selling) would give much better purchase without faffing. Also 2.5m is long, had loads of waste on small patch jobs they need to stock a 1.5m or 2.0m section to stop that happening. A decent working product overall.

Lines are true. Proper quality.

Five Stars! Top gear for 6mm render. Runs dead straight. Saved time on the edging.

Perfect fit, uPVC cust cleanly. The 100mm mesh bonded bang on. Top quality.

flexes right, cuts dead true. Sorted!

Fitted a treat, material feels solid. Made those final edges spot on.

Went up easy, proper sharp finish. Brill!

This bead is mint. Straight lines easy, no messing about. Bang on for the price, proper kit!

Proper job. Kept a perfect line for the 10 mil render, spot on value.

Exactly the spec required: Saved the job getting the precise mesh I needed. It’s proper durable uPVC and worked straight across my 6mm/10mm systems. Solid kit.

Easy to use. Sharp edges & holds firm with wall movement. Sound.

Brill, works good. Saved us a faff.

Proper top quality bead. Goes up a doddle and the lines are spot on.

felt thick straight. Flies up dead easy.

needed that strength. Sorted.

Lengths varied. Plastic too brittle. Not worth a fiver.

Got the 10mm bead for EWI. Arrived dead straight, cuts clean, makes for a proper finish.

Solid bit of kit. Easy to install and gives a much cleaner, straighter line than the alternatives. Saved me time.

Top quality. Gave me clean, sharp edges fast. Spot on kit, saves the faff.

Spot on uPVC quality. Dead straight, fit was easy, which saved us tme on the EWI system. Mesh sits perfectly in the basecoat. Sharp corner finish. Recommend.

Best bead for the money. Did the 10mm render spot on.

Spot on straigbht edge doddle to fit.

Brill! The Best Stop Bead I've Fitted This Year. Absolute quality stuff, mate. Used this uPVC stop bead on a 10mm render job and it delivered exceptional straight lines. Spot on. The 100mm mesh wing integrated flawlessly with the basecoat, made the whole set-up feel rock solid

the system integrity is much better now. Cutting the jPVC was easy with no cracking

that's a massive bonus over the brittle cheap alternatives floating about (that recycled tat). It accommodated minor structural movement too. Quick delivery, came securely psckaged when they promised. Excellent value considering the quality finish. Highly recommend this specific bead to fellow tradesmen. Exceeded expectations!

Spot on! Quality Gear. Used a fine-tooth blade and it cut dead clean on site zero splintering which saves major time detailing. Mesh wing bedded into the scratch coat perfect for a seriously keen straight edge. Will be sticking with these for the next job.

Decent bit of kit. Cut quick and the 100mm mesh keyed in well. Not perfectly rigid (slight warp noted) but great value vs aluminium alternatives. Will buy more.

Decent bead overall. Paid a bit more for the supposed quality but it was not consistent. Three lengths were sound felt like proper kit. Fourth one had a flimsy soft spot on the bead which made holdin a dead straight line a bit of a faff when pulling the mesh tight. Not bad but the advertised 'sharp clean edges' were slightly diminished needs more finishing effort than I hoped. It will do the job but for this price I expected faultless manufacturing.

Stop bead worked brilliant, was a doddle to fit. Delivery team were sound.

Bead went in dead easy. Proper crisp finish sorted.

Dead straight line. Superior flex compared to the rubbish I used last job. The mesh sunk right into the basecoat. Sorted.

good, sharp finish for render. Just wish the profile wasn't so light.

Proper bit of kit. Mesh bonded quick and gave me a dead straight line. Way better than cheaper alternatives. Saved time.

Sound piece of kit, functioned perfectly on the 6mm elevation and the mesh bedded nicely. That 2.5m length is always awkward to shift in the van, which is a bit of a faff logistically. Also, the dense uPVC makes it slightly harder to cut than I'm used to, and I did have one length that was marginally warped on the flat. Good stuff overall for system integrity, but the higher price point compared to some means you notice those slight compromises on QC and application time.

Proper garbage. it came obwed and snaped trying to cut it. Zero instruction.

Cracking quality bead. Feels really durable not flimsy plastic like some stuff out there. Used it on a 10mm system and the finished edge is razor sharp looks mega. EWI delivery was spot on too, which frankly is worth paying a few quid extra for the hassle saved. Top marks, will be stocking up on this one.

Brill! Dead straight edges. Flexible. Job's a good un.

Stops beads breaking. Clean job.

Brilliant gear. Exactly what I needed for EWI.

rUBBISH. The lprice for this cheap brittle plastic is xetortionate. snapped and shattered in the cold weather, totally ruining the cornrr work. it was warped and the mesh peeled straigh off the profile. NOT for 3mm render, it made a proper shadow line. Now i have to pull it all out. costs me time and money.

good robust bead. Used on 6mm render and kept a dead straight line. Slight scuff mark on one length that needed trimming but great value.

Proper kit, really quick install gave a superb edge!

Proper strong bead, gives sharp edges. Sorted.

Cut clean and was a proper doddle to apply. Sits spot-on for 10mm system and leaves a perfectly clean edge. Brill!

Good bead for 10mm. Proper sharp edge, but pricey.

absolute liberty on the length they are short! Getting lines straight was a proper pain, the uPVC felt bit soft and broke when trimming. Overpromised on impact resistance. Messed up my job.

Stop buying the cheap stuff lads. This uPVC is sound; you can work it without it splitting or cracking under pressure. That 100mm mesh wings properly anchor it too, keeping everything straight. Brill finish. I won't use anything else now. Spot on, proper bit of kit.

Quality kit, nice give, straight edges. Dead on.

Bead did the job, but pricey. Had to fiddle a bit during fitting just to get a proper true line, needed tighter tolerance.

Job's a good 'un. Laid straight mesh bedded flawlessly. Saved loads of faff.

Brill! Super easy to fit. Edges are rock solid and dead straight. Will buy again

Did the 10mm job brilliant, finish is proper straight and tough.

Quality stuff. Spot on finish and went in dead easy. Brill.

Quality kit, dead straight. The 100mm mesh bedded down solid, saved ages sorting the corners. Best price too, sorted.

perfect fit, handles 3mm finish no problem. Robust gear, dead chuffed.

Brill! Integrated mesh saved hours. Went on fast and kept the line true.

Solid bit of kit. Beds in fine with the adh and gives the proper sightlines we need for the 10mm system. Support was decent they sorted a quick spec check for me over the phone. Finish is spot on but aligning it perfect on a tight radius was a faff. The flexibility of the uPVC kept trying to spring back slightly cost a few minutes to nurse it into position. Minor niggle for an otherwise sound product. Recommended.

Proper good stuff. Sorted.

Proper job. Went in dead easy.

Cracking bit of kit for the 6mm render system. Cut easy, fits solid, lines are dead sharp.

Brilliant bead, fitted perfect on the 6mm render system. Lines are spot on & look proper sharp. Took a star off 'cos delivery was a day late.

Dead easy this one, brill.

Finally a uPVC bead that holds a crisp square edge. Easy workin', mesh fully integrated.

Amazing bead. Solid uPVC and dead straight, easy to bed in. Got a professional edge first time, sorted.

Robust kit. Cut easy and held solid. Bob on finish.

Brill kit for 10mm render system. Good, robust material achieved sharp edges. However, dimensional consistency wasn't perfect, requiring extra mesh tape on one run, which worries me about long-term flexing. Warehouse missed a pack initially too, causing a faff.

Superior bead. Straight runs, saved us loads a time. Mesh integrates brilliantly. Hedl up to the rain, solid choice.

Brill! Dead easy install and puts a brilliant square finish on the corner. Won't warp like cheaper beads.

Held the line true, no flex when fitting. Better than that galvanised muck.

Dead sound stuff, better quality than expected for the price. Fits quick, gave me the straight edges I needed. Job done.

Worth the extra few quid.

beads are sound. Flex and mesh bedded right. Order picking was sluggish.

brilliant kit, makes a clean tsop easy. Sorted.

Bead great. 2.5m waste awk.

Gives a proper crisp finish, spot on.

Stuck well, crisp edge. Service spot on too.

a bit flimsy for stop bead work + had some dodgy loose mesh. Ok finish but seriously overpriced compared to competition.

Good bead for 10mm. Packaging was shoddy.

Brill uPVC bead. Went in fast and gave a proper sharp line.

Mesh works a treat for the basecoat. Sharp corners. A little pricy tho.

Proper brilliant! Sat dead straight first time. Cuts clean & bedded into the basecoat no drama. Sharp edge.

brill bead, delivered sharp edges for the 10mm render system, absolute upgrade from metal. Lost a star cos the unit price and shipping were a bit steep for basic kit.

Proper chunky uPVC bead. Dead straight lines and the integrated mesh saved a load of faff taping corners. Sharp finish on the reveals. Excellent value kit.

Proper good bead, the uPVC cut clean and it was a doddle to fit on the base coat. Saved me loads of faff time and the finished corners look dead sharp, sorted!

The bead itself is bang on. Sits dead true, gives a mint sharp edge, and the 100mm mesh cured in quick. Way better than previous gear I paid more for. Proper job.

ok for the job but it feels a bit flimsy and cost too much

Solid bead for 6mm render. Gets you a spot on edge. No rust risk, brill. Cost a bit too much, mind; felt like the plastic should be heavier gauge.

Straight runs stiff enough and easy to cut this plastic bead. Integrated the 100mm mesh sound, proper clean edge on the 6mm render. Saved time. Sound.

good edge for 10mm render. Mesh feels a bit light.

Proper quality uPVC, not the brittle stuff. Gives a dead sharp plumb line every time. Sorted.

Dead easy to cut, proper job.

top quality bead, dead straight linre!

Proper EWI spec kit. Dead straight and decent uPVC thta cuts well. Pre-meshed bead saved me a lot of messing about on reveals. Worth the price.

Review Title: Great stuff!Review Body:Bead is spot on for the price decent gear. Used on a 10mm system and it pulls a proper straight edge every time finished corners were nice and clean. It’s flexible enough to be fitted without fuss and the mesh wing ties into the basecoat mix easily.Only knocked a star because the admin side of the order was a bit of a headache. Asked for five only four were the stop bead profile the last one was a different type entirely. Had to call up wasting a good half hour on the phone and site while I waited on a quick redelivery. Not ideal when you’ve planned your day out.But product itself is sound and driver was helpful with the long lengths. Overall satisfied with the gear.

Spot on! Perfect for 6mm render. A doddle to cut and fix, absolutely zero flexing. Top quality material for the price.

Proper job, gave me a dead straight line.

Proper quality. Amazing! Best 10mm stop bead out there. None of the flimsy stuff you usually find, this uPVC is robust and held my line dead straight. Mesh wing went in smooth. Saved me chasing a plumb line for hours. Definitely paying for quality here.

Good quality bead. Sharp finish sorted, proper job. Price is a tad high for one. Needed extra adh to sit flush on a tricky section.

proper shoddy muck. cracked when scoring. it isn't impact-resistant.

Decent, sharp edges on 10mm system. Proper job. Great value for the full spec bead. Packaging was a bit iffy—had a dented corner.

No more cheap rubbish. This bead is straight and works good. Proper job.

Good uPVC stop bead, straight line on the 6mm render. Great price. Shame one end bent a little on arrival. Decent kit, wil re-order.

quality bead, 10mm fit spot on. Took a day too long to get here.

Decent gear for the render system. It gave me sharp edges and the mesh integrated solid into the basecoat. Lost a star because one length was slightly warped. Bit of a snag.

Bead didn't warp in the sun which is a massive win. Locked into the basecoat perfect.

Dead easy to fit and cut, looks spot on. Sound kit.

Solid kit, did the trick on my 6mm render system. The 2.5m length was precise, which is brill—meaning zero waste, which is a big win. The mesh wing integrated perfectly into the adhesive basecoat without fuss, and the finish looks professional for the price paid (£5.16 incl. VAT).

Just a couple of minor gripes: it felt slightly less rigid than my old brand when I was dealing with tricky corner details, forcing a bit too much careful trimming to hold the line. That cutting, actually, was slightly challenging overall. Found a wee scuff on unwrapping, but it's nothing that won't be covered up by the time the job's finished. Good, sound component that largely met expectations.

Spot on kit for the 10mm system. Super tough didn't crack when I leaned on it and pulled a perfectly sharp corner. Driver was sound too.

Needed a 10mm profile, delivered prompt. U P V C is super robust, cut clean no warping like cheaper brands. Saved huge time, straight edge achieved easy. The 100mm mesh is great for integrity. Proper job.

Top quality uPVC it took the 10mm render thickness perfect. Finish is mint and install was quick saved loads of time. Miles better than that cheap rubbish I tried.

Stayed straight on site. Passed snagging easy. Brill!

it's decent gear and makes a crisp edge for the render. But the thin gauge uPVC feels too flexi, and one length had a kink from being loosely stacked for transit. Good, but expensive.

Brill bit of kit this is. Paid slightly more than a competitor bead but glad I did. The uPVC material felt sound, none of that thin floppy plastic. The 100mm mesh is massive for the EWI system, keyed in perfect to the basecoat and made the corners rock solid.

It goes on quick, zero messing about truing it up. Got a crisp straight edge ready for the top coat. Top quality bead, saved me loads of time during the final render stages. Proper job. Will be buying these again.

Mesh attached perfectly, no fiddling. Got a dead straight line and saved us loads of time. Proper job.

Handles the basecoat mix no bother. 100mm netting is decent. Got good flex too, which sorted out a rough return on site. Performance is five star, but the cost felt slightly steep. Quick service helped.

Cracking bit of kit. Easy fit and gives a dead sharp edge for the 6mm render. Great value for this quality.

Material felt a bit too flexible honestly had to put in extra mechanical fixings. The mesh trim was fiddly, took too long. Decent bead but price feels high for this lower grade plastic.

Proper straight edge. Dead easy to install on the 6mm render.

Spot on kit. Holds dead straight and the mesh is solid. Worth paying a few quid extra.

Edges are spot on and it cuts great. Saved a load of time. Proper job!

brill kit. Dead easy to install gave us a crisp line. Superior to the usual plastic beads, proper value.

Amazing stuff! Really robust uPVC. Mesh wing went into the basecoat a doddle, and gave me super sharp lines. Quality item. Sorted.

Proper job bead. Dead easy install and makes the corner line look sharp. Solid kit.

Did job, sharp lines. Quick post.

Good stuff, goes straight in. Not as rigid as the last batch, bit brittle.

brill product! Finally a bead that doesn't feel like brittle rubbish. Good flex & proper straight line. Won't buy cheaper brands again.

Finally a bead that stays straight! Wish I'd bought this first.

Spot on quality and fantastic value. Didn't warp undr the skim and gives properly sharp, clean edges. Sorted. Will be buying more of this bead.

great Bead, But Delivery Was Slow.

The product itself is spot on. Used it on a 6mm scratch coat system and it went on alright, easy enough to bed into the adh. Got me the sharp, clean edge I needed. Reliability component is high, seems like decent uPVC too, weatherproof as described. The quality is a decent step above the basic ones.

Docking a star mainly because the delivery arrived late—the tracking updates were rubbish and cost me half a morning waiting on site. Also, I've since seen similar 2.5m spec going for a bit less (like from Rendit or IBB). Need EWI to sharpen up logistics and maybe drop the price a few pence.

Proper quality bead, flexy for a fast install. Mesh holds the basecoat. Cracking, crisp edge.

Proper job bead. Superior material quality, flexible but solid. Held up perfectly against heavy rain and left razor sharp edges. Bang on!

uPVC quality is sound, gives a sharp line, mesh bedded nicely. Priced high; need 3m option.

Saved time. Dead straight lines on the 10mm. This robust kit is miles better than the budget plastic I ried.

brill! Gets a perfectly sharp corner on the EWI render. Mesh keys into the basecoat straight away. Saved me hours!

below Par. This stuff's dead flimsy and warps immediately couldn't get a sharp edge. UV resistance is rubbish, already yellowing after two weeks.

Brill! Best stop bead I've fit. Flexed easy without snappin'. Perfect for the 10mm reveal, job done fast.

Brill finish. Straight edges, dead easy to fit.

Quality PVC, did the 10mm perfect. Can't fault it.

Straight lines sorted! Best uPVC bead I've used.

Spot on for 10mm render. Got a clean, straight edge.

Good bit of kit. That 100mm mesh wing really locks in, keeping the edge straight. Does the 10mm render bang on. Must have for all the lads.

fALSE ADVERTISING! liars this isn't uv-proof. absolute tat. 3 days mild sun & the ulpvc went bone-dry brittle and chalky white. completely USELESS for a ernder system. it shatteresd when i tried cutting it. now i

'm gutted. wasted a half day's wqages removing this rubbish from the basecoat.

Dead easy to fit the integrated mesh cut loads of hassle. Every piece was bang on straight too. Proper job.

Super easy to install! Top quality material.

Spot on quality uPVC. Way better than others, weatherproof finish will hold shape long term.

avbsolute rubbish total joke. The parcel was lost then relivered late. This bead shattered instantly and the mesh came off. £5.16 for this flimsy muck is madness.

uPVC dead straight. Perfect in the basecoat.

uPVC too flexible bit warped. Mesh ripped easy, too pricey.

This bead is spot on! uPVC quality miles better than previous gear. Easy cuts, straight as a die.

flimsy uselses plastic, flexes too much. trying to get a true corner is impossible, wasted my time. way too expensive for this rubbish.

Bang on for 10mm render. Proper clean edges spot on. Saved time! Brill!

Dead easy kit. Decent kit. Perfect fit for 10mm render. Gives a pro edge.

Solid uPVC. Lays dead straight, gave a sharp edge. Good value.

Spot on for 10mm. Superior to the old brittle beads I used. My new go-to.

Cracking uPVC bead. Dead straight and a doddle to fix in. Proper professional finish. Tough, excellent value.

Arrived straight and fast, unlike some cheap rubbish. Cuts easy, perfect straight edge, proper weather proof.

Proper robust quality. Staight finish, spot on. Installation was dead quick!

brill. uPVC is proper durable, edges dead straight. 100mm mesh is key.

Proper job this. The uPVC feels much more durable, did not crack up when cut to size, which is always an issue with the cheaper stuff. Perfect fit for the 10mm render coat. Made achieving that razor-sharp line effortless. Adhesive grip on the mesh was brill. Quality stuff, saves time on site.

Proper kit! Fitting this bead was a doddle. Gives a great finish, spot on.

Brill bead, straight lines bang on for the 6mm render. Just watch the burrs when cutting.

No movement cracks. Top qualjty bead! Sorted.

Proper job bead. Essential for the corners, gives a mint sharp finish, and straightens easy. Miles better than the metal junk.

good Kit, Spot On Edge.Bead works well, gives a proper clean edge. Mesh felt superior to some cheaper stuff I

is have used before. Easily knocks on to the basecoat for the EWI system.

The cost feels a bit high versus similar profiles on the market, and their online stock was miles off which held up the site schedule for a couple days. Decent kit but pricey.

Cracking bead, it laid straight as a die. Saved me a load of time, superb quality for this price!

Top quality bead. Colleague told me to grab this one proper sound recommendation. Rns straight and gave a mint sharp finish for the render. It cuts clean too easy work. The mesh locked into the basecoat saving me time messing about. Took a few knocks already and it's tough, dind't warp outdoors. Wish they'd stock a 3m length option but still 5 stars, it's spot on. Delivery driver was decent, and packaging protected everything perfectly.

Great stuff! Achieved straight edges very easy.