Rate & Review

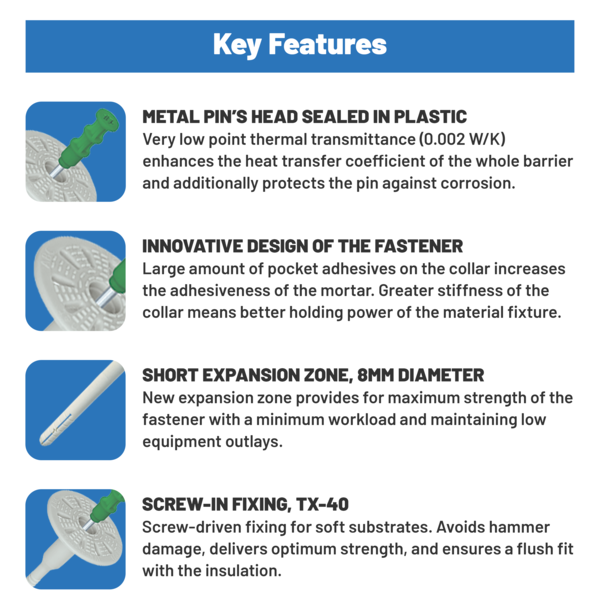

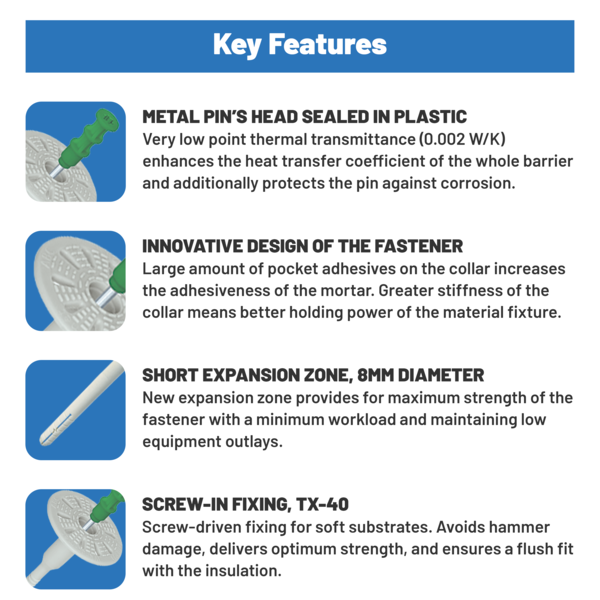

8mm Screw Fixing with Metal Pin & Short Expansion Zone

SKU: WKR-WKTHERM-S-08095

Reviews & Ratings

TX-40 drive made fitment a doddle. Brill.

Sorted my 150mm insul boards properly. Very solid hold. Just a bit of a faff crewing into the hard brickwork.

Porper quick fit anchor is spot on.

TX-40 is proper fast. Rock solid in the AAC block!

Brill kit, fast TX-40 drive.

Held strong in the dense concrete. TX-40 screw-in meant a nice flush finish every time. Lost a star cause I can't use 'em on the spare PIR I had kicking aronud. Massive faff.

Brill. 200-pack makes life easier and it holds fast. Sorted.

first off the customer sevice line was a complete joke they fobbed me off for hours then the fixings showed up damaged anyway. worst part? these 8mm screw fixings are absolute rubbish. i needed these for concrete but the first 4 i tried setting down wih the tx-40 stgripped or bent the supposed xteel pin. i only tapped them gently just seating the collar and the osft scrap metal bent rite over useless. proper miffed, i've got boards fixed with pins i litedally cant trust now. this stuffs a proper liability avoid avoid avoid.

Cracking hold on the concrete substrate passed the pull-out test no drama so they're solid. Chuffed with the sealed steel pin

estoreduces bridging worries massively. Sit flush don't dish the boards. Only four stars 'cos the pace was slower than I'd expected. Needed grunt on the TX-40 and AAC depth adjustment was a real faff. Plus, they aren't wood fibre compatible, which is a letdown for my next job. Decent value for the compliance though.

Decent fixing tho felt a bit expensive compared to rivals. Coating looked scratched too.

Top kit! Quick, solid anchor.