10mm Hammer Fixing with Plastic Pin - 120mm

The 10mm Hammer Fixing with Plastic Pin is a mechanical fixing for external wall insulation (EWI) systems. It combines a durable polyethylene body with a fibreglass-reinforced pin for high impact resistance during installation. The telescopic sleeve ensures the washer sits flush with the insulation, reducing thermal bridging and improving system performance. It’s designed to transfer wind loads and provide long-term stability.

Suitable Insulation Boards

| Insulation Type | Compatibility |

|---|---|

| EPS (Expanded Polystyrene) | Compatible |

| XPS (Extruded Polystyrene) | Compatible |

| Mineral Wool | Not compatible |

| PIR / Phenolic (e.g., Kingspan) | Not compatible |

| Wood Fibre | Not compatible |

Compatible Substrates (ETA Categories A–E)

| ETA Category | Substrate | Compatibility |

|---|---|---|

| A | Concrete | Compatible |

| B | Solid ceramic brick / silicate | Compatible |

| C | Ceramic block | Compatible |

| D | Lightweight aggregate blocks | Compatible |

| E | Aerated concrete (AAC) | Compatible |

If the substrate condition is uncertain, carry out a pull-out test to confirm suitability.

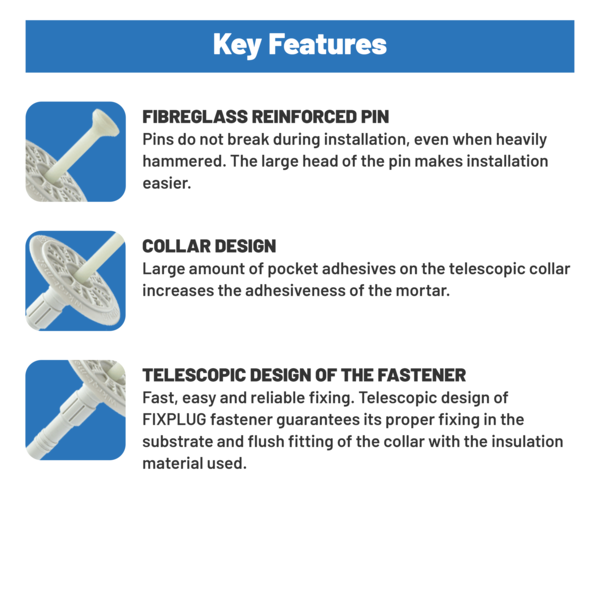

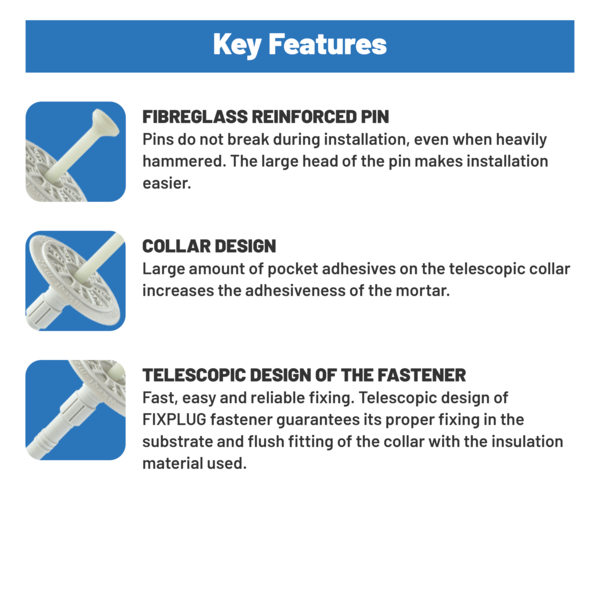

Key Features

-

Fibreglass-reinforced pin minimises breakage when hammered.

-

Telescopic sleeve ensures correct embedment and a flush washer finish.

-

Washer with adhesive pockets to improve bond with basecoat.

-

Designed to resist wind suction forces in ETICS/EWI systems.

-

ETA-15/0373 assessed.

-

Fast, reliable installation.

Sizes & Box Quantities

| Size (Ø10mm) | Box Quantity |

|---|---|

| 120 mm | 200 per box |

| 140 mm | 200 per box |

| 160 mm | 200 per box |

| 180 mm | 200 per box |

Select length to suit insulation thickness + adhesive layer + required embedment depth.

Application

Preparation

-

Mark out the fixing grid to suit the system design and wind-load zone.

-

Check for hidden services (cables/pipework) before drilling.

-

Select the correct drilling mode for the substrate: use rotary-only for aerated/voided blocks; use hammer mode for dense concrete/brick as appropriate.

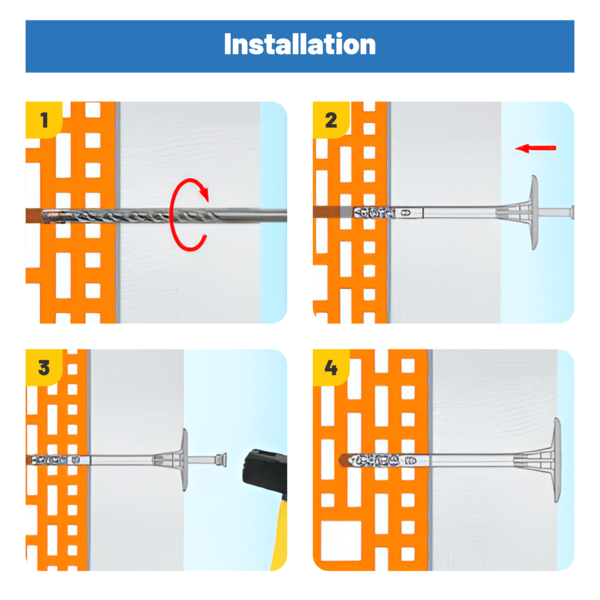

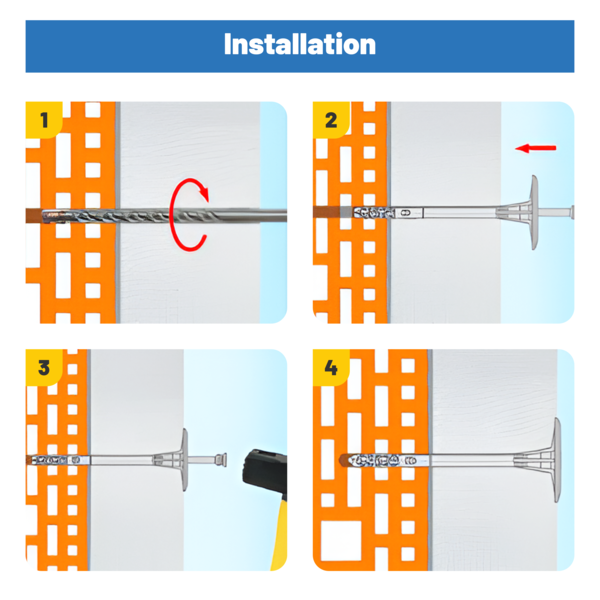

Installation steps

-

Apply adhesive to the boards per your EWI specification and place boards tightly with staggered joints.

-

Drill perpendicular through the board into the substrate using the selected drilling mode.

-

Insert the fixing body and then drive the pin until seated. Do not over-drive or dish the board surface.

-

Install the specified number of fixings per board, paying particular attention to corners, reveals and high-suction zones.

-

Once all boards are fixed, proceed with basecoat and reinforcement mesh according to the system specification.

Fixing pattern & density

-

Follow the project design; as a guide, many façades use 4–6 fixings per m², with additional fixings around openings and building corners.

-

Keep consistent edge distances and avoid placing fixings too close to board edges or through board-to-board joints unless specified.

Quality checks

-

Periodically verify pull-out resistance on-site where substrate variability is suspected.

-

Replace any fixings that spin freely or fail to grip, and re-drill if necessary.

Frequently Asked Questions

The 10mm Hammer Fixing with Plastic Pin (FIXPLUG-10) is designed to securely fasten EPS insulation boards to a wide range of substrates, including categories A, B, C, D, and E. These fixings are suitable for concrete, brick, and blockwork, providing a fast and reliable method for securing insulation as part of an external wall insulation system.

The telescopic collar design ensures that the fixing sits flush with the insulation surface, guaranteeing proper installation. It also enhances adhesive grip by increasing the contact area with mortar, helping to create a stable and secure bond between the insulation and substrate.

Typically, 6 fixings per square metre are used when installing EPS insulation boards. However, this may vary depending on the building’s location, exposure to wind, and manufacturer guidelines. Additional fixings are usually required around openings such as windows and doors.

Yes. The FIXPLUG-10 Hammer Fixings are compatible with EPS insulation boards installed using EWI-220 EPS Basecoat Adhesive. Together, they form a secure, high-performance system suitable for both residential and commercial projects.

Rate & Review

10mm Hammer Fixing with Plastic Pin

SKU: WKR-FIXPLUG10-120

Reviews & Ratings

Overall rating

Have something to say?

Rate 10mm Hammer Fixing with Plastic Pin

Mark

Robert

lee

Michal

Andy

Ledjon

Philip

Derek

Ben

Stephen

keith

Janey

Grzegorz

Anthony

Will

Rajeev

Gavin

Dmytro

Michal

Jordan

Valeriy

Simon

Darren

Marius

Glenn

George

Emma

HARMEET

Vic

Andrew

Stuart

shane

Chris

James

Chris

Dragos

Dwayne

Pardeep

Benjamin

Doni

Ben

Deepak

Helen

Peter

Melvyn

evaldas

John

RICHARD

Chieko

MARIUS

Alexander

Audrius

Ian

Brian

HARISH

George

Kevin

Hysen

simon

MARCIN

jackie

GRAHAM

Michael

Jordan

Mark

Nospam

DAVID

Craig

David

Mick

james

Simon

Paresh

carl

Paula

Okan

Glenn

Shahram