The 10mm Hammer Fixing with Plastic Pin & Short Expansion Zone is a hammer-driven fastener for external wall insulation (EWI) systems. The body is polyethylene and the glass-fibre–reinforced plastic pin delivers high impact resistance during installation while minimising thermal bridging. Its short expansion zone and innovative sleeve help the washer sit flush with the insulation for a stable, long-term fix. Recommended for securing polystyrene insulation in ETICS applications.

Suitable Insulation Boards

| Insulation Type |

Compatibility |

| EPS (Expanded Polystyrene) |

Compatible |

| XPS (Extruded Polystyrene) |

Compatible |

| Mineral Wool |

Not compatible |

| PIR / Phenolic (e.g., Kingspan) |

Not compatible |

| Wood Fibre |

Not compatible |

Compatible Substrates (ETA Categories A–E)

| ETA Category |

Substrate |

Compatibility |

| A |

Concrete |

Compatible |

| B |

Solid ceramic brick / silicate |

Compatible |

| C |

Ceramic block |

Compatible |

| D |

Lightweight aggregate elements |

Compatible |

| E |

Aerated concrete (AAC) |

Compatible |

If the substrate condition is uncertain, carry out a pull-out test to confirm suitability.

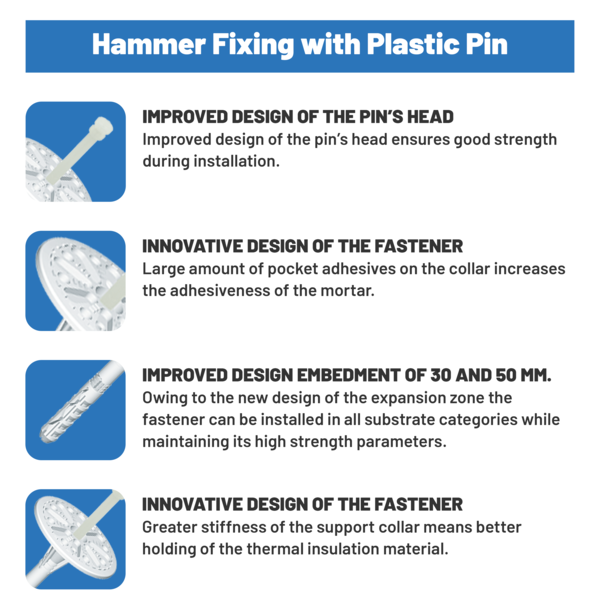

Key Features

- Glass-fibre–reinforced plastic pin resists breakage and limits thermal bridging.

- Short expansion zone for efficient anchorage and reduced drilling effort.

- Innovative sleeve ensures a flush finish to the insulation surface.

- Special connection flange improves stability under wind suction loads.

- ETA-16/0509 assessed for EWI/ETICS applications.

- Fast, reliable hammer-in installation.

Sizes & Box Quantities

| Size (Ø10mm) |

Box Quantity |

| 70 mm |

200 per box |

| 90 mm |

200 per box |

Select length based on insulation thickness + adhesive layer + required embedment depth.

Application

Preparation

- Mark out the fixing grid to suit the system design and wind-load zone.

- Check for hidden services (cables/pipework) before drilling.

- Use rotary-only mode for hollow blocks/AAC; use hammer mode for dense concrete and brick where appropriate.

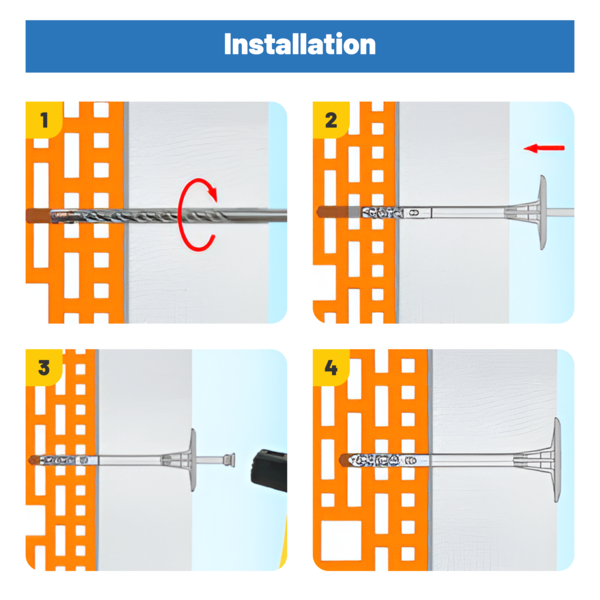

Installation steps

- Apply adhesive to boards per your EWI specification and place boards tightly with staggered joints.

- Drill perpendicular through the insulation into the substrate; clean dust from the hole.

- Insert the fixing body and hammer the plastic pin until the washer seats flush; do not over-drive or dish the surface.

- Install the specified number of fixings per board, adding extras around corners, openings and high-load zones.

- Proceed with basecoat and reinforcement mesh in line with the system specification.

Fixing pattern & density

- Typical guidance: 4–6 fixings per m², with increased density in edge and corner zones.

- Maintain consistent edge distances; avoid placing fixings too close to board edges or through joints unless specified.

Quality checks

- Carry out pull-out tests where substrate variability is suspected.

- Replace any fixing that spins or fails to grip; re-drill if necessary.