Render Carrier Boards

Log in to save items on your shopping lists and access them on all your devices. Guest lists are deleted after 90 days.

Choose engineered render carrier boards as the ideal substrate for thin coat render systems on external walls. Designed specifically for high performance façades, each carrier board provides a stable surface, excellent durability, and reliable compatibility with decorative render finishes.

Render carrier boards for high performance external wall systems

In modern external wall systems, the carrier board sits over the frame or sheathing to receive a thin coat system. Used with the correct primers, base coats, mesh, and finishes, render carrier boards help deliver impact resistant façades that meet demanding performance targets and provide complete peace of mind.

What is a render board?

A render board (or render carrier board) is a construction board designed to accept renders. Unlike standard plasterboard, it is moisture tolerant, robust, and tested for exterior applications. Common sizes include 1200 mm x 2400 mm with thickness options to suit the system build-up.

Types of render carrier boards

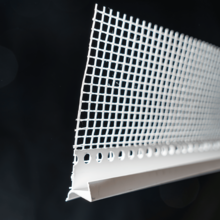

Typical options include fibre cement board and cement-bonded boards. Each carrier type offers good workability and a textured face or keyed surface that improves adhesion in thin coat render systems. Always follow manufacturers’ guidance for fasteners, joints, and movement detailing.

Fibre cement board and its advantages

Fibre cement offers high strength, fire resistance, and excellent dimensional stability in harsh weather. Its impact resistant, engineered surface is suitable for polymer-modified base coats and decorative render. It is a robust solution for both timber frame and steel frame buildings.

Cement board vs render carrier board

While “cement board” is a broad term, a true carrier board is designed specifically for renders: it has a suitable surface, edge details, and certification for external use. Many cement boards are suitable, but check that the exact product is approved for external render systems, not just internal applications.

Construction boards for timber frame and steel frame buildings

On timber frame and steel frame projects, the board is fixed to studs over sheathing boards or directly to rails, then finished as part of the thin coat system. Correct detailing prevents water ingress and protects against rot at junctions, while maintaining drainage and ventilation where required.

Applications of render carrier boards

Use on façades, soffits, and sheltered ceilings where a durable render is needed. Carrier boards are also used with insulation in mixed build-ups, provided the system is designed as a compatible assembly.

Can you render straight onto a render board?

Yes—when the thin coat system is followed. Apply primer (if specified), a polymer-modified base coat with embedded mesh, then the decorative render. Rendering directly without the correct base layer is not recommended.

What is the best board to render onto?

The best choice depends on frame type, exposure, and system specification. For most projects, a tested fibre cement board or cement-bonded carrier board approved for external use is the ideal substrate.

Are render boards waterproof?

Boards are moisture tolerant rather than fully waterproof. The complete system—primer, base coat, mesh, and finish—provides water shedding. Seal penetrations and follow joint details to protect the substrate.

Installation and fixing of render carrier boards

Use system-approved fixings at the specified centres. Select anchor type and lengths to suit the substrate (timber or metal studs, masonry rails) and board thickness. Maintain staggered joints, leave movement gaps where required, and ensure boards are fixed flush without over-driving fasteners.

How to install render carrier board?

-

Mark stud lines and set out the first course level.

-

Cut with a fibre-cement blade; support edges to avoid break-out.

-

Offer the board to the wall, fix from the centre outwards, and keep edges straight.

-

Tape or treat joints as specified; prime the surface if required.

-

Apply base coat, embed fibreglass mesh, then complete the decorative render.

Best practices for high performance external render systems

-

Choose boards and base coats tested together for system compatibility.

-

Respect drainage, movement, and flashing details at windows, reveals, and terminations.

-

Use corrosion-resistant fixings; confirm embedment and pull-out on the actual substrate.

-

Follow curing times and weather limits; avoid loading the surface too early.

Shop high quality render carrier boards online

Browse our range of render systems and fixings, then add boards and accessories to your basket. Product pages show stock status, pricing ex VAT and inc VAT (with VAT added at checkout), and delivery options to your postcode. If you need a recommendation for a specific application or thickness, contact our team and we will help match the board to your system.