- Types of trowels

- Regular trowels

- Design and features

- Applications

- Pool trowels

- Design and features

- Applications

- Venetian trowels

- Design and features

- Applications

- London Brick trowel

- Design and features

- Applications

- Notched trowels

- Design and features

- Applications

- Bucket trowels

- Design and Features

- Applications

- Skimming Blades

In the world of construction and plastering, trowels are more than just tools; they are the extension of a craftsman's hand, essential in bringing precision and finesse to the work. With their varied shapes and sizes, these tools play a pivotal role in a wide array of construction tasks. From laying bricks to creating smooth, plastered walls, trowels are indispensable in ensuring that each job is done with the utmost accuracy and professionalism. Trowels come in various types, each meticulously designed for specific tasks. At their core, they are all about applying, shaping, and smoothing materials like mortar, plaster, and concrete. The variety in trowel designs is a testament to their versatility. Some are crafted for broad, flat surfaces, offering an even spread over large areas. In contrast, others are more specialised, with shapes and edges designed for specific tasks like smoothing corners or creating decorative textures. The choice of a trowel can greatly influence the efficiency of the task at hand, the ease of application, and the quality of the final product. In addition to their functional diversity, trowels also embody the skill and craftsmanship of the construction trade. A well-chosen trowel not only makes the job easier but also ensures a higher quality of work, showcasing the artisan's skill and attention to detail. Given the variety, this complete guide to trowels will look to discuss their uses and features and ultimately demystify the choice of trowel for your job. We stock a wide range of manufacturers but have the closest relationship with Regal & Barnes. They manufacture and provide an incredibly high-quality and diverse range of rendering and plastering tools.

Types of trowels

Regular trowels

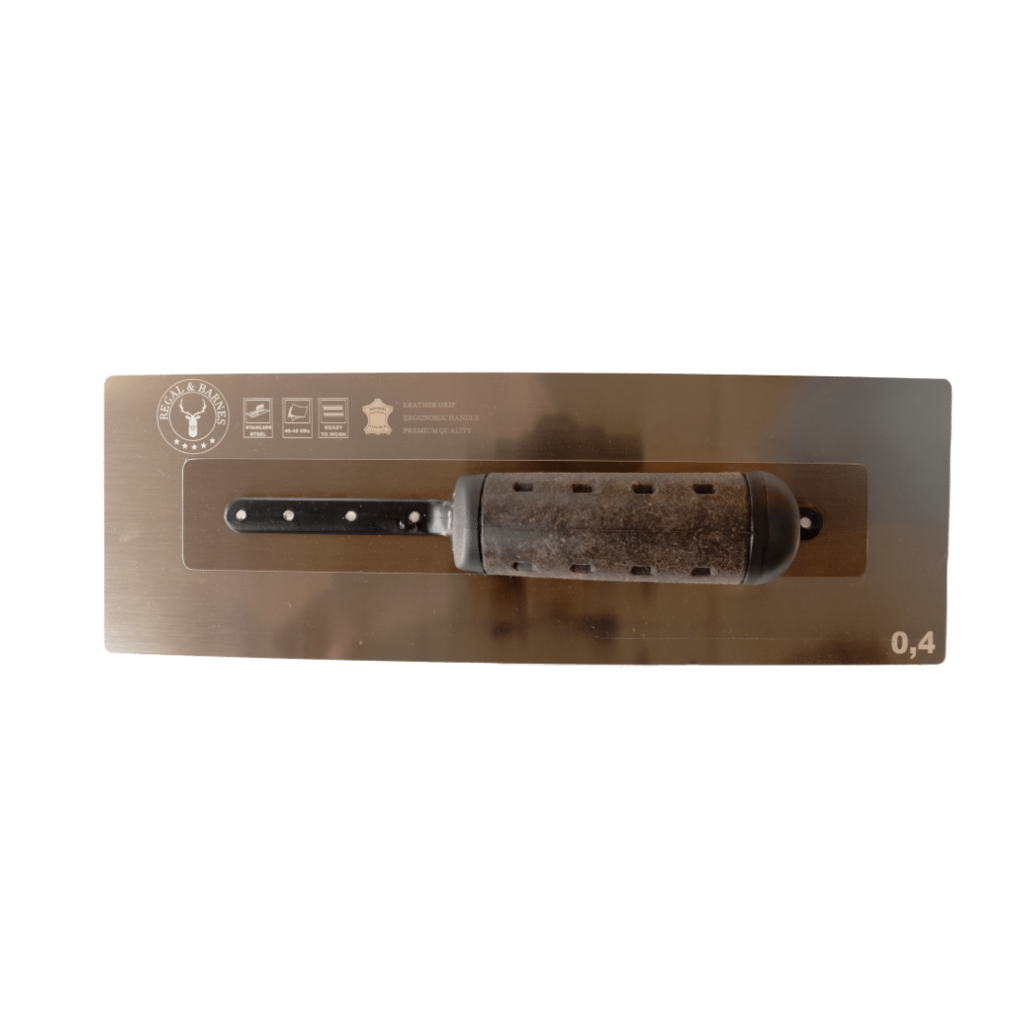

Regular trowels, often the quintessential image that comes to mind when one thinks of trowelling, are versatile tools that play a fundamental role in masonry, plastering, and concrete work. Characterised by their flat, rectangular blades, these trowels are designed for a range of applications, making them a staple in the toolkits of many craftsmen.

Design and features

- Blade: The blade of a regular trowel is typically made of high-quality steel, ensuring durability and rigidity. It's flat and rectangular, allowing for a smooth application of materials. The size of the blade can vary, with larger blades used for covering more surface area and smaller ones for more precision work.

- Handle: Ergonomics play a crucial role in the design of a regular trowel's handle. Typically made from wood, plastic, or rubber, the handle is designed to provide comfort and reduce hand fatigue during extended use. Some handles are even designed to minimise vibration, reducing strain on the hands and wrists.

- Balance: A well-balanced trowel reduces the effort needed to apply materials evenly. The balance between the handle and the blade is crucial for precise control and ease of use, especially during long hours of work.

Applications

- Applying mortar and plaster: Regular trowels are most commonly used for applying mortar in bricklaying and for plastering walls. The flat surface of the blade is ideal for spreading material evenly over a surface or for laying down a consistent layer of mortar between bricks.

- Smoothing and levelling: Beyond just applying material, regular trowels are essential for smoothing and levelling surfaces. Whether it's evening out plaster on a wall or levelling concrete on a floor, the flat blade helps achieve a uniform finish.

- Shaping and edging: While not as specialised as other trowels, regular trowels can also be used for shaping and creating edges in plaster and concrete. The corners of the trowel can be used to create clean lines and angles.

The regular trowel's significance in construction and plastering cannot be overstated. Its versatility makes it an indispensable tool for a wide range of tasks, from laying the foundation of a building to putting the finishing touches on a wall. The skill of using a regular trowel effectively is a hallmark of experienced craftsmen, showcasing their proficiency and attention to detail.

Pool trowels

Pool trowels are specialised tools designed specifically for the unique challenges of smoothing the curved surfaces found in pool construction and other similar projects. Their distinctive design sets them apart from other trowels, making them an essential tool for achieving a seamless and professional finish in rounded and contoured areas.

Design and features

- Rounded edges: The most notable feature of pool trowels is their rounded edges, which differentiate them from the more common square-edged trowels. These rounded corners prevent the tool from digging into or gouging the wet material, especially along the curves and contours of a pool.

- Wide, flat blade: Pool trowels typically have a wider and flatter blade than regular trowels. This design helps in achieving a smooth, flat surface over large, curved areas without leaving lines or marks, which is particularly important in the aesthetically focused work of pool finishing.

- Flexible steel construction: The blades are often made from flexible stainless steel, allowing the trowel to bend slightly to the contours of the pool. This flexibility is key in ensuring a consistent finish on curved surfaces.

Applications

- Smoothing pool surfaces: The primary use of pool trowels is in the smoothing and finishing of pool interiors. They are adept at working with materials like plaster, pebble finishes, and other pool-specific coatings.

- Contoured areas: Beyond pools, these trowels are also useful in any project that involves curved or contoured surfaces, such as fountains or sculptural elements, where precision and a smooth finish are required.

- Large, flat areas: While designed for curved surfaces, the wide blade of the pool trowel also makes it suitable for finishing large, flat areas where a regular trowel might leave lines or marks.

In pool construction, achieving a smooth, uniform surface is not just about aesthetics; it's also about functionality and durability. Pool trowels play a critical role in this aspect. The right trowel can ensure a finish that is not only visually appealing but also withstands the test of time and constant exposure to water and chemicals.

Furthermore, the use of pool trowels requires skill and experience. Mastering the technique to apply coatings evenly over curved surfaces is a testament to a craftsman's expertise. The ability to manoeuvre the trowel smoothly over the contours of a pool demonstrates a high level of proficiency in plastering and finishing work.

Venetian trowels

Venetian trowels are a specialised type of trowel primarily used in the application of Venetian plaster and other decorative plastering techniques. Their unique design and functionality make them ideal for achieving the polished, high-gloss finishes that are characteristic of Venetian and polished plaster work.

Design and features

- Smaller, more flexible blade: Venetian trowels typically have smaller, narrower blades compared to regular trowels. This smaller size provides greater control and precision, which is crucial for the detailed work involved in applying Venetian plaster. The blade is also more flexible, allowing for the subtle manipulation of the plaster to achieve a smooth, polished surface.

- Pointed or trapezoidal shape: Many Venetian trowels have a pointed or trapezoidal shape, which assists in reaching into tight spaces and corners. This shape is instrumental in creating uniform finishes across all areas of a surface, including hard-to-reach spots.

- High-quality stainless steel: The blades of Venetian trowels are often made from high-quality stainless steel. This material is chosen for its durability and resistance to corrosion, which is important when working with lime-based plasters and other materials that can be corrosive.

Applications

- Applying Venetian Plaster: The primary use of Venetian trowels is in the application of Venetian plaster, a type of decorative plaster known for its smooth texture and glossy finish. The trowel's design helps in layering the plaster thinly and evenly, building up layers to achieve the desired depth and sheen.

- Polishing and burnishing: Beyond application, these trowels are used for polishing and burnishing the plaster to achieve a high-gloss finish. The flexibility and smooth edge of the blade are perfect for pressing and compacting the plaster surface, resulting in the characteristic shine of Venetian plaster.

- Detailed decorative work: Venetian trowels are also suited for other types of detailed decorative plasterwork where precision and a smooth finish are required.

Venetian trowels are essential in the art of decorative plastering. Their specific design caters to the need for a high degree of precision and control. The skilful use of a Venetian trowel can transform a plain wall into a work of art, showcasing the craftsmanship and artistic ability of the plasterer.

Moreover, the technique of applying Venetian plaster is as much about the tool as it is about the material. The trowel's ability to smoothly apply, shape, and polish the plaster is central to achieving the desired aesthetic effect. This makes the Venetian trowel not just a tool, but an integral part of the artistic process in creating luxurious and elegant finishes.

London Brick trowel

London Brick Trowels are essential tools in the field of masonry, specifically designed for the task of bricklaying. They are distinguished by their unique shape and construction, tailored to meet the demands of laying bricks efficiently and effectively. These trowels are a testament to the specialised nature of masonry tools, where each design element serves a specific purpose.

Design and features

- Diamond-shaped blade: The most distinctive feature of a London Brick Trowel is its diamond-shaped blade. This design allows for more versatility in loading and spreading mortar. The pointed tip helps in spreading mortar in tight spaces, while the wider part of the blade is used for carrying and applying larger amounts of mortar.

- Forged steel construction: London Brick Trowels are typically forged from a single piece of high-carbon steel. This construction ensures durability and strength, which is crucial for withstanding the rigours of bricklaying. The steel is also tempered to achieve the right balance of hardness and flexibility.

- Wooden or soft grip handle: The handles of these trowels are designed for comfort and efficiency. They may be made of traditional wood or modern materials with a soft grip. This design helps reduce hand fatigue during long hours of bricklaying and provides a firm, comfortable grip for better control.

Applications

- Bricklaying: The primary application of London Brick Trowels is in bricklaying. The shape and size of the blade are perfect for applying the right amount of mortar, and its pointed tip helps in spreading mortar on bricks accurately and efficiently.

- Buttering bricks: These trowels are also used for 'buttering' – applying mortar to the end of a brick before placing it. The trowel's pointed end is particularly useful for this task, allowing for precision in applying mortar.

- Cutting and trimming mortar: Beyond applying mortar, the sharp edge of a London Brick Trowel can be used to trim excess mortar and create a clean, finished look between bricks.

The London Brick Trowel is more than just a tool; it's an extension of the bricklayer's hand. Its design is optimised for the bricklaying process, ensuring efficiency and precision in each motion. The balance and feel of the trowel in hand are critical, as they affect the speed and quality of the bricklaying work.

Moreover, the skill of using a London Brick Trowel effectively is a hallmark of a professional bricklayer. It requires practice and precision to apply mortar evenly and swiftly, qualities that are honed over time and experience.

Notched trowels

Notched trowels are specialised tools designed primarily for tile setting and flooring work. Their distinctive feature is the series of notches or "teeth" along the edges of the blade, which play a crucial role in the application of adhesives. The design of these trowels is tailored to ensure a consistent and optimal spread of adhesive, crucial for the proper installation of tiles and similar materials.

Design and features

- Notched edges: The defining characteristic of notched trowels is their serrated edge, which comes in various sizes and shapes. The size and shape of the notches determine the amount of adhesive that is left on the substrate. Common notch shapes include square, V-shaped, and U-shaped, each serving different types of tiling materials and adhesives.

- Flat blade base: Despite the notches, the base of the trowel blade is flat, allowing for a smooth and even spread of adhesive over the surface. This flat base is crucial for ensuring that the adhesive is uniformly distributed before the notches create the desired pattern.

- Ergonomic handle: Similar to other trowels, notched trowels feature ergonomic handles designed to provide comfort and reduce hand fatigue. This is particularly important given the repetitive nature of tiling work.

Applications

- Applying adhesive for tiles: The primary function of notched trowels is to apply adhesive for tile setting. The notches create ridges in the adhesive, which collapse when the tile is set, ensuring a strong bond and reducing the risk of air pockets.

- Ensuring consistent adhesive thickness: The design of the notches ensures a consistent thickness of adhesive, which is crucial for a level tile installation. Different notch sizes cater to different tile sizes and types, ensuring that the right amount of adhesive is used for each job.

- Versatility in tile work: Notched trowels are versatile and can be used for various types of tiles including ceramic, porcelain, and natural stone. The choice of notch size and shape depends on the specifics of the tiling project.

In tile setting, the even application and proper bonding of tiles are critical for both the aesthetics and longevity of the installation. Notched trowels facilitate this by ensuring that the adhesive is applied in a way that supports the weight of the tile and provides a strong bond. The right trowel and notch size can significantly affect the outcome of a tiling project.

The use of notched trowels also speaks to the precision required in tile work. The right amount and distribution of adhesive are essential to prevent issues such as tile cracking, lifting, or unevenness. This makes the notched trowel an indispensable tool in the tiler's arsenal, blending functionality with the necessity for precision in application.

Bucket trowels

Bucket trowels are specifically designed for the efficient and effective retrieval of material from buckets. These trowels are distinct in their shape and purpose, catering to the need for minimising waste while ensuring easy access to materials like mortar, plaster, or adhesives.

Design and Features

- Short, wide blade: The blade of a bucket trowel is shorter and wider compared to traditional trowels. This design is ideal for scooping materials out of buckets or containers. The broad blade allows for the retrieval of a substantial amount of material in one go, enhancing efficiency.

- Slightly curved blade: Many bucket trowels have a slight curvature to their blade, enabling them to fit comfortably against the rounded interior of a bucket. This curvature helps in scraping out materials thoroughly, reducing waste.

- Robust construction: Given their usage, bucket trowels are often constructed with robustness in mind. They are typically made from hardened steel to withstand the rigours of scraping against rough surfaces inside buckets.

Applications

- Retrieving material from buckets: The primary use of a bucket trowel is to retrieve materials like mortar, plaster, or tile adhesive from buckets. Its design ensures that you can scoop out almost all the material, reducing waste.

- Applying and spreading material: While primarily used for scooping, bucket trowels can also be useful for applying and initially spreading material onto surfaces, especially in situations where precision is less critical.

- Mixing small quantities: Bucket trowels can also be handy for mixing small quantities of material directly in the bucket, providing a convenient solution for minor adjustments to mixes.

In the construction and plastering trades, efficiency and minimising waste are key. Bucket trowels contribute significantly to these aspects by ensuring that materials are fully utilised, and little is left behind in containers. This not only saves on material costs but also makes the job cleaner and more efficient.

Moreover, the comfort and ease of use offered by bucket trowels make them a preferred choice for professionals who spend long hours handling materials. The ergonomic design lessens hand fatigue and makes the tool more user-friendly.

Skimming Blades

Skimming blades are crucial in achieving smooth surfaces in plastering or drywall work. They come in various types:

- Notched blades: Similar to notched trowels, these blades create texture or pattern in plaster before they set. They are excellent for specific decorative finishes or for preparing a surface for tiling.

- Flexible blades: These blades are thinner and more flexible, designed for final finish coats. They adapt to the surface contours, allowing for a smoother finish.

- Wide blades: Used for covering larger surface areas, wide blades help in efficiently applying and smoothing plaster or joint compound over wide expanses.