When it comes to External Wall Insulation (EWI) systems, there's a significant characteristic that often goes unnoticed, yet it plays a crucial role in ensuring the system's longevity, aesthetics, weather resistance, and thermal performance. This important characteristic is impact resistance. If your EWI system has increased impact resistance, the whole system is more durable. As such, it is more likely to satisfy the timeframes of any warranties.

What is impact resistance?

Impact resistance is the ability of a material or system to resist the effects of sudden force or shock. In the context of EWI systems, impact resistance refers to how well the insulation, render, and other components can withstand physical impacts without damage. This includes anything from a stray football hitting the wall to harsh weather conditions, or even small accidental bumps from day-to-day activities.

Measuring and testing

The measurement and testing of impact resistance are highly specialised processes. The tests are conducted in a manner that simulates real-world scenarios to yield accurate and reliable results. Different standards and procedures are followed globally. However, the European technical approval guideline, ETAG 004, is widely adopted due to its comprehensive and practical approach.

The ETAG 004 guideline recommends a specific procedure for the impact resistance test of External Thermal Insulation Composite Systems (ETICS), also known as EWI systems. It outlines a controlled method of testing by using a falling-weight impactor.

The Falling Weight Impact Test

This test involves dropping a 1kg weight onto the EWI system sample from varying heights to simulate different levels of impact energy. The weight is therefore designed to mimic real-world impacts. Additionally, the height from which it is dropped represents the intensity of the force.

- Preparation of the sample - A sample of the EWI system is prepared, including all its layers from the insulation material to the external render or cladding. The sample should represent the actual system used in field conditions.

- The test - The sample is then subjected to the falling weight impactor test. The weight, often a spherical or cylindrical object, is dropped from different heights, starting from a lower height and gradually increasing.

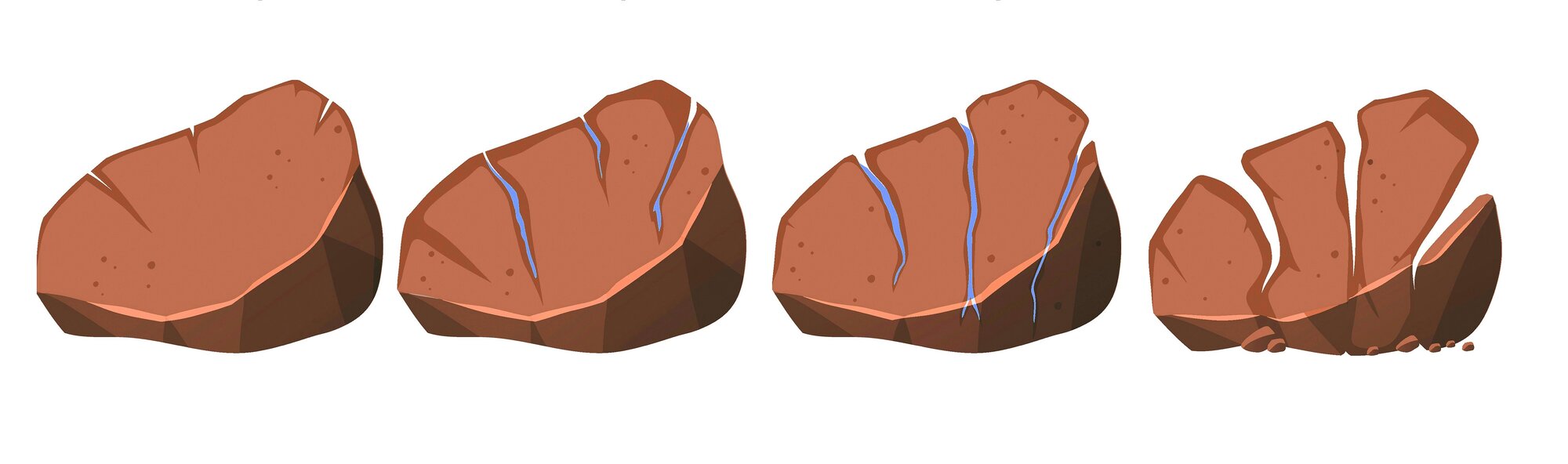

- Assessment of damage - After each drop, the sample is inspected for damage. The damage is classified into categories, such as no visible damage, minor cracks, major cracks, or penetration.

- Classification of impact resistance - The maximum height from which the weight is dropped without causing significant damage (usually defined as no penetration) is noted. The impact resistance is then classified into five categories (from I to V) according to ETAG 004. Category I indicates the highest impact resistance.

Other testing methods

While the falling weight impactor test is standard, other methods can also be used based on the specific requirements or conditions that the EWI system might face. For instance, the pendulum impact test is another common method used to measure impact resistance. This involves swinging a pendulum with a certain weight at the end to strike the sample. The energy absorbed by the sample upon impact is then measured to assess its impact resistance.

It's crucial to note that impact resistance testing should be carried out in a controlled environment. These results form an essential part of the information used by architects, engineers, and builders when selecting the right EWI system for a particular application.

Source: https://industrialphysics.com/

EWI system components and their impact resistance

Impact resistance is enhanced by combining all the components of an EWI system. Each one has inherent resistance to mechanical compression, with varying levels of compressive strength. Some components are specifically developed to have a higher compressive strength. For example, Kingspan K5 insulation boards have a compressive strength of 120kPa. As such, they are ideal for areas more susceptible to incidental or accidental impact, such as roadside properties or urban developments.

Insulation - Materials like EPS or Mineral Wool are commonly used due to their excellent thermal performance and reasonable impact resistance. The thickness and density of the insulation can affect its impact resistance. As aforementioned, Kingspan K5 is the premier option when it comes to impact resistance and compressive strength.

| Insulation type | Compressive strength |

| Kingspan K5 | 120kPa |

| Mineral Wool | ≥60kPa |

| EPS | 70kPa |

Render or Cladding - The external face of the EWI system, which provides the first line of defence against impacts. Renders are usually a mix of cement, sand, and lime. Cladding, on the other hand, can be made from various materials like timber, metal, or PVC. Both options can provide additional impact resistance, with their performance varying based on their composition and thickness.

Fibreglass Reinforcing Mesh - This is applied within the basecoat render layer and significantly improves the impact resistance of the system. The mesh works to distribute the force of an impact across a wider area, reducing the likelihood of localised damage.

Fixings - These are used to mechanically secure the insulation to the substrate. While not directly contributing to impact resistance, proper use of fixings ensures the stability of the system, preventing dislodging under impact.

Why do you need impact resistance in EWI systems?

As the external layer protecting your home, EWI and ETICS systems are susceptible to various forms of impact and damage. If they are more durable, they can also protect your home for longer.

Buildings must endure a host of environmental and human-induced impacts. These range from hailstones and wind-borne debris to inadvertent knocks from moving vehicles, and furniture. Therefore, an EWI system with high impact resistance is equipped to withstand such challenges, ensuring physical durability.

The long-term implications of high-impact resistance extend beyond just durability. Materials that resist impact effectively tend to last longer, showing resistance to daily wear and tear. This longevity means that the building stays insulated for extended periods, reducing the frequency of maintenance or replacement and thereby curtailing associated costs.

Aesthetics also come into play. An EWI system susceptible to damage may result in visible dents or cracks on the exterior of a building, which compromises its aesthetic appeal. High resistance to impact helps maintain the visual integrity of the building's facade.

Moreover, impact resistance is often coupled with increased resistance to weather elements. EWI systems demonstrating high impact resistance can typically withstand harsh weather conditions such as heavy rain, snow, and freeze-thaw cycles, further enhancing their durability.

Finally, the thermal performance of an EWI system is directly influenced by its impact resistance. Damage to the insulation layer can lead to the formation of thermal bridges - zones where heat transfer between the building's interior and exterior is more efficient. This can compromise the insulation's effectiveness, leading to increased energy consumption for heating or cooling the building. By resisting impacts, the EWI system prevents the formation of these thermal bridges, maintaining its thermal performance and energy efficiency.