In recent years, the UK construction industry has seen a significant shift towards sustainable and energy-efficient solutions. Among these, External Wall Insulation (EWI) systems stand out for their potential to transform both the functional and aesthetic aspects of a building's exterior. Despite their increasing popularity, many are unaware of the intricate components that contribute to the efficiency and effectiveness of these systems. One such vital component, often overlooked, is beading. This piece aims to shed light on its importance and the role it plays within EWI systems.

Why is beading important?

Structural integrity

Beading's primary role within External Wall Insulation (EWI) systems is to safeguard and enhance the system's structural integrity. Here's a breakdown of how it achieves this:

- Reinforcement of edges and corners: The edges and corners of any structure are inherently vulnerable to damage. Beading reinforces these critical areas, ensuring they can withstand external pressures such as wind, rain, and even minor physical impacts.

- Stress distribution: As temperature fluctuates, building materials can expand and contract. Beading helps in evenly distributing this stress across the insulation surface, reducing the risk of cracks or deformations.

- Protection against external factors: Whether it's adverse weather conditions or mechanical impacts, the outer layer of an EWI system is continuously exposed. By strengthening the system's exterior, beading acts as a shield, reducing wear and tear.

- Support for insulation panels: Beading aids in holding insulation panels in place, preventing them from shifting or detaching over time. This ensures the insulation layer remains consistent and effective throughout its lifespan.

Aesthetic finish

The visual appeal of a building's exterior is often one of the first impressions it offers to onlookers. Beading in External Wall Insulation (EWI) systems plays a significant role in ensuring this appearance is not just functional, but also aesthetically pleasing. Here's a detailed look into its contributions:

- Smooth transitions: Beading helps achieve smooth transitions between different sections of the wall, ensuring there are no abrupt changes or gaps. This continuity lends a seamless look to the building's façade. Smooth transitions also impact the prevention of cold bridging which is highly detrimental to the thermal performance of the whole system.

- Defined edges: Proper beading around windows, doors, and other architectural features give a neat and defined edge, emphasising the design elements and enhancing the overall architectural aesthetics.

- Texture and pattern consistency: EWI systems can have various textures and patterns. Beading ensures that these designs are consistent across different sections, avoiding any mismatch or irregularities that could disrupt the visual flow.

- Colour uniformity: Over time, certain areas of a building might be more exposed to sunlight or weather elements, leading to uneven fading. Beading can help maintain a consistent colour tone by offering additional protection to vulnerable sections, ensuring the façade retains its intended appearance.

- Highlighting features: Specialised beading can be used to accentuate certain design elements, making them stand out or adding an extra layer of detail to the building's exterior.

[caption id="attachment_69025" align="aligncenter" width="1024"] Crisp edge achieved thanks to beading[/caption]

Crisp edge achieved thanks to beading[/caption]

Prevention of cracks

The integrity of a building's façade is paramount not only for aesthetic reasons but also for the long-term durability and protection of the structure. Cracks, even minor ones, can lead to significant issues if left unaddressed. Beading within External Wall Insulation (EWI) systems plays a pivotal role in preventing the onset of these cracks. Here's how:

- Thermal expansion and contraction: With changing seasons and temperature fluctuations, building materials naturally expand and contract. Beading assists in managing these shifts, ensuring that the movement is uniform and doesn't result in stress points which could lead to cracking.

- Protection from mechanical stress: Everyday occurrences, such as the slamming of doors or the impact from moving objects, can create mechanical stresses on the walls. Beading helps absorb and distribute these stresses, reducing the likelihood of cracks forming from such impacts.

- Enhanced adhesion: Beading improves the adhesion between the insulation material and the finishing render. This strong bond ensures that the exterior surface remains intact, even under adverse conditions.

- Moisture management: Water is one of the primary culprits behind cracks, especially if it seeps into the insulation and freezes. Some beads are designed to wick away moisture, ensuring that water doesn't accumulate and lead to freeze-thaw cycles that can crack the façade.

- Flexibility: Modern beading materials are designed to be flexible, allowing for slight movements without causing breakage. This flexibility is crucial in absorbing shocks and preventing cracks from forming or propagating.

[embed]https://youtube.com/shorts/aSkIFLKkxN4?feature=shared[/embed] Flexibility of modern materials (EWI Store Youtube)

Enhanced durability

Every homeowner and construction professional desires a building solution that not only meets its functional requirements but also stands the test of time. In the realm of External Wall Insulation (EWI) systems, beading plays a significant role in achieving this longevity. Here's an in-depth look at its contribution to durability:

- Protection against environmental factors: Be it relentless rain, scorching sun, or biting frost, the external surfaces of a building are constantly exposed to the elements. Beading provides an extra layer of protection against these factors, ensuring the insulation and finish remain undamaged over prolonged periods.

- Resistance to biological factors: Mould, mildew, and algae can degrade the quality of insulation and affect its performance. Certain beading materials come with properties that resist these biological growths, ensuring the system remains effective and aesthetically pleasing.

- Impact absorption: Accidental knocks, debris during storms, or even playful ball games can impact the walls. Beading, especially on vulnerable edges and corners, provides a buffer, absorbing these impacts and preventing potential damage.

- Maintenance reduction: With effective beading, the need for regular maintenance, repairs, and touch-ups is significantly reduced. This not only ensures the EWI system remains in top condition but also translates to cost savings in the long run.

- Uniform load distribution: Beading helps in evenly distributing both static and dynamic loads across the EWI system. This uniform distribution prevents the concentration of stress in particular areas, reducing the risk of wear and tear.

Improved water run-off

Water is a persistent challenge for any building's exterior. If not managed effectively, it can lead to a host of issues, from cosmetic blemishes to structural damages. Beading in External Wall Insulation (EWI) systems plays a crucial role in managing water run-off, ensuring the façade remains dry and protected. Here's how:

- Drip bead design: Specifically designed drip beads, often positioned at the base of walls or above openings, channel water away from the surface. This ensures that water doesn't linger on the façade, reducing the risk of seepage or damage.

- Surface breaks: Beading can create subtle surface breaks, guiding water downwards and preventing it from spreading sideways. This is particularly important in preventing water from entering vulnerable areas like window recesses.

- Prevention of water pools: By ensuring effective run-off, beading helps prevent the formation of water pools at the base of walls. These pools can lead to rising dampness, a challenge that can compromise both the aesthetic and functional aspects of a building.

- Protection against freeze-thaw cycles: In colder climates, trapped water can freeze and expand, causing cracks or other damages upon thawing. Effective water run-off, facilitated by beading, reduces the chances of this freeze-thaw damage.

- Reduced algal and moss growth: Standing water or consistent dampness can be a breeding ground for algae and moss. By ensuring swift water run-off, beading minimises the conditions these organisms thrive, maintaining the visual appeal of the façade.

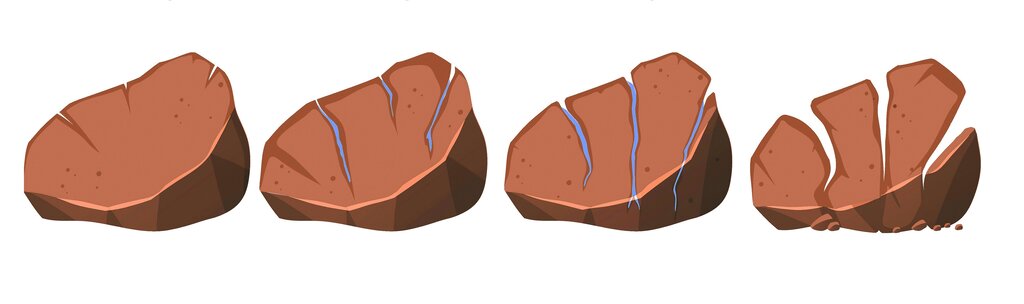

[caption id="attachment_64040" align="aligncenter" width="1024"] Freeze-thaw cycle that beading helps to prevent[/caption]

Freeze-thaw cycle that beading helps to prevent[/caption]

Types of beading used in EWI systems

Corner -Designed with a reinforced angle, corner beads wrap snugly over external edges. Their primary role is to safeguard these vulnerable corners, ensuring they remain sharp and undamaged, thereby lending a polished look to structures. Drip - Featuring a protruding edge, drip beads are strategically positioned at wall bases or above openings. Their design channels water away, preventing it from cascading down walls, which helps maintain the facade's pristine appearance. Stop - Characterised by a flat profile with a squared finish, stop beads offer a clean termination point for renders. They not only ensure a tidy finish but also guard the render ends against potential fraying. Bellcast - With its distinctive rounded edge, bellcast beads find their place at the base of rendered walls. Their design funnels water away from wall bases, averting potential pooling and the consequent rising damp issues. Window - Shaped to complement window or door frames, these beads ensure seamless integration of insulation around openings. Beyond aesthetics, they act as a protective barrier for these especially exposed areas. Arch - Boasting flexibility, arch beads adapt to curved or arched architectural features. They guarantee a consistent insulation and render finish, even on these intricate non-linear surfaces. Movement - Incorporating a pliable section, movement beads span across expansion joints or shifting areas. They absorb and adjust to the building's natural expansions and contractions, thwarting potential cracks from thermal or structural shifts. Monocouche - Tailored for monocouche renders, these beads, often crafted from stainless steel or PVC, ensure a neat finish. They enhance both the structure's functionality and aesthetic appeal, making them indispensable for single-coat render applications.