Rendering in the rain is never particularly easy. It may seem that this is an issue that you cannot overcome. However, in this blog, we're going to discuss the process of rendering in adverse weather. The best conditions for rendering can be read about here! We will also provide a few possible issues and tips on how to alleviate them.

The issues with rendering in the rain

Rendering in the rain and in any adverse weather is something you would ideally try to avoid. Projects do come with time pressures, so striking whilst the iron is hot is crucial. Using breaks in the weather is the best way to avoid any unwanted issues. Any water ingress during the process can cause the following issues. You can read our blog on how to prevent water ingress and damp here.

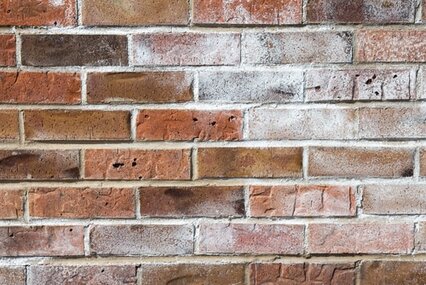

Lime bloom - All cementitious materials are susceptible to this occurrence, sometimes referred to as efflorescence. It is unsightly, appearing as a general lightening or discolouration on coloured cement-based products that are otherwise sound and fully cured. It doesn't result from a fault with the product; rather, it results from the intolerance of cement to certain conditions during its early stage of hydration.

Structural damage - If there is water or moisture present during the rendering process, it can soak into the walls of your property. Ultimately, this can lead to penetrating damp and rot. Both these issues can affect the structural integrity of the foundations.

Trapped moisture - In the same vein as structural damage, trapped moisture can be particularly damaging to timber frames, leading to timber rot.

Colour/texture inconsistency - The presence of water in any render or paint can alter the final colour finish. The render comes in different grain sizes, and any alteration of the consistency due to rendering in the rain could result in a finish that does not set and cure correctly.

Strong winds - Strong winds may initially seem advantageous when you're considering rendering in the rain and other poor weather. In theory, they will cut curing times, right? The primary issue is that strong winds can actually dry the render too quickly. In turn, this leaves render highly susceptible to cracking. The finish could also end up being patchy.

The solutions

The repeated cooling and thawing in the winter months can also cause hairline cracks. The material expands and contracts, creating small disruptions to the uniformity of the wall. With continuous cooling and thawing, these cracks can expand further, allowing more water ingress. This is a serious risk when rendering in the rain. So what are the solutions to these issues?

Check forecast - The simplest way to find the best time to complete the render stage of your project. Check the forecast often to see when you can work.

Protect substrate - It's absolutely crucial that the substrate is kept clean and dry. The adhesion of your basecoat, and consequently, the adhesion of your insulation and render systems rely on this. The best way to do this is to ensure you have installed sufficient tarping and waterproof mesh on your scaffolding. This will protect your substrate from water ingress and high winds.

Keep products safe - Your products need the same attention and consideration as your substrate. They must stay cool and dry. It is crucial to keep them elevated off the floor to avoid any water soaking into the bottom of the materials. Any form of dry storage like a container is the best way to prevent the weather affecting your materials.

Start early - Use all the time available to you. There may be small windows of dry and sunny weather on winter mornings, where you can jump onto rendering.

Be prepared - Scheduling based on the forecast and delivery of your materials is very important. If you know your window of good weather, you can plan how much of your project you can render. Therefore, you can also ensure that all your materials and tools are ready. Preparation also includes having the right workforce in place. You'll require at least two people, wherein, one applies the render and one follows to rub up. This maintains a wet edge and ensures that there are no trowel lines.

Our products

At EWI Store, we offer several products which can help you work despite the adverse weather. Whilst rendering in the rain is pretty much impossible unless you create an atmospheric bubble around the project, colder weather and smaller curing windows won't stop you. The Winter Adhesive is particularly useful as the basecoat in the winter months as it allows you to work down to 0°C. Microfibres provide extra flexibility, which is crucial given the volatile drying times in bad weather. The product is also hydrophobic and frost-proof, so it is uniquely suited to winter work.

Our Render Accelerator is a high quality solution that can be used to accelerate the curing process. If you live in a colder climate, where the drying process takes a long time, this product is a worthwhile investment. It allows installers to continue to install thin-coat render systems throughout the winter months. EWI-020 works to speed up this curing process, allowing for a faster job completion rate.

The premier render choice for any weather affected areas is Silicone Render, as it is highly hydrophobic. The flexibility will also work to combat the cooling and thawing process discussed above.

Lastly, tarpaulins and temporary downpipes are excellent ancillary products for weatherproofing your project. Tarps keep water out, while temporary downpipes help with incomplete guttering systems.