- Eco-friendly sustainable materials

- Natural and renewable materials

- Recycled materials

- Low environmental impact on production

- Recycling and reusing

- Recycled materials

- Examples

- The role of reusing materials in EWI

- Reducing carbon footprint

- Energy-efficient manufacturing processes

- Use of renewable energy sources

- Sustainable material sourcing

- Reducing waste and improving material efficiency

- Transportation and logistics

- Enhancing durability and performance

- Life Cycle Assessment and sustainability

- Promoting green building certifications

In recent years, the conversation around building practices has increasingly focused on sustainable building materials. One area where this shift is particularly notable is in the realm of external wall insulation (EWI). EWI plays a pivotal role in enhancing the energy efficiency of homes and buildings, but its sustainability quotient depends significantly on the materials used, the production processes, and the long-term impacts on the environment. In this blog, we'll explore the strides being made in the EWI sector to promote sustainability.

Eco-friendly sustainable materials

Natural and renewable materials

Natural materials are at the forefront of the eco-friendly EWI movement. These materials are derived from renewable resources and have a significantly lower environmental impact compared to synthetic alternatives. Some of the key natural materials include:

- Wood Fibre: Derived from sustainably managed forests, wood fibre insulation is biodegradable and has a low embodied energy, meaning it requires less energy to produce. It also offers excellent thermal properties and can regulate indoor humidity levels, enhancing indoor air quality.

- Cork: Harvested from the bark of cork oak trees without harming the tree, cork is a renewable resource. Cork insulation panels are not only highly insulative but also naturally fire-resistant and durable. The production process of cork insulation is energy-efficient and generates almost no waste, as all parts of the bark are used.

- Hemp and Flax: These plant-based materials are gaining popularity for their low environmental impact and excellent insulation properties. Hemp and flax insulations are carbon-negative, meaning they absorb more carbon dioxide during their growth than is emitted during their processing.

Recycled materials

Using recycled materials in EWI helps reduce waste and the demand for virgin resources. Recycled materials can come from various sources and can be just as effective as new materials in terms of insulation performance.

- Recycled Plastic: Innovative companies are turning to recycled plastics to create insulation materials. These plastics are often sourced from consumer waste, such as PET bottles, and transformed into insulation boards or beads.

- Glass Wool: Made from recycled glass, glass wool is a common insulation material. The production process melts down the glass and spins it into fibres, creating an effective insulator with good thermal and sound insulation properties.

Low environmental impact on production

The sustainability of EWI materials also depends on the environmental impact of their production process. Eco-friendly materials are typically those that require less energy to manufacture and result in lower emissions. For instance, materials that are locally sourced reduce transportation emissions, and those produced using renewable energy further reduce their carbon footprint. Eco-friendly EWI materials should not only be in their production but also in their performance. Materials that offer high durability and require less maintenance contribute to sustainability by reducing the need for replacements and repairs over time. Moreover, materials that enhance energy efficiency in buildings lower the overall carbon footprint of the structures they insulate.

Recycling and reusing

Recycled materials

- Reduction in Landfill Waste: By using recycled materials in EWI, we can significantly reduce the amount of waste sent to landfills. Construction and demolition waste constitutes a large percentage of total landfill waste, and recycling materials for EWI can help mitigate this.

- Lower Carbon Footprint: The process of recycling materials for EWI usually consumes less energy compared to manufacturing new insulation materials. This reduced energy expenditure translates into a lower carbon footprint for the insulation products.

- Conservation of Resources: Recycling helps in conserving natural resources. For instance, using recycled glass or plastic reduces the need for new raw materials, thus preserving natural resources and reducing the environmental impact associated with their extraction and processing.

Examples

- Recycled Glass Wool: Glass wool, often used in EWI, can be made from recycled glass bottles. The recycled glass is melted and spun into a fibrous insulation material, which provides excellent thermal properties.

- Expanded Polystyrene (EPS) with Recycled Content: EPS, commonly used in EWI systems, can include recycled polystyrene. Manufacturers are increasingly incorporating recycled EPS into new products, thereby reducing the reliance on virgin materials.

- Recycled Plastic Insulation Boards: Some insulation boards are now being manufactured using recycled plastics. These boards are not only environmentally friendly but also provide effective insulation and are often water-resistant and durable.

The role of reusing materials in EWI

- Upcycling EWI Materials: Upcycling involves repurposing materials for a use that is of higher value than the original. In EWI, this could involve using discarded materials, like wood offcuts or recycled cotton, in insulation products.

- Modular and Reusable EWI Systems: Some EWI systems are designed to be modular, allowing for components to be easily disassembled and reused in different buildings or settings. This approach extends the life of the materials and reduces waste.

- Refurbishing EWI Materials: In some cases, EWI materials removed from buildings can be refurbished or reconditioned for reuse. This process often involves cleaning, repairing, or reprocessing materials to ensure they meet the necessary standards for insulation performance.

Despite the benefits, there are challenges in recycling and reusing materials for EWI. These include ensuring the quality and safety of recycled materials and overcoming logistical hurdles in collecting and processing used materials. However, as technology advances and awareness increases, the potential for recycling and reusing materials in EWI is expected to grow. Innovations in material processing and a stronger emphasis on circular economy principles in the construction sector are paving the way for more sustainable EWI solutions.

Reducing carbon footprint

Energy-efficient manufacturing processes

- Optimising Production Line Efficiency: Manufacturers are increasingly adopting energy-efficient technologies in their production lines. This includes using advanced machinery that requires less energy to operate and implementing process improvements that minimize energy waste.

- Heat Recovery Systems: Many insulation materials require high-temperature processes. By installing heat recovery systems, manufacturers can capture and reuse heat that would otherwise be wasted, significantly reducing energy consumption.

Use of renewable energy sources

- Solar and Wind Power: More factories are transitioning to renewable energy sources like solar and wind power for their energy needs. This shift not only reduces carbon emissions but also lessens the dependency on fossil fuels.

- Biomass Energy: In some cases, manufacturers are using biomass boilers, which burn organic waste materials, to generate energy for production processes. Biomass is considered a renewable source of energy and can help reduce carbon emissions compared to traditional fossil fuels.

Sustainable material sourcing

- Locally Sourced Materials: Using locally sourced materials can significantly reduce the carbon footprint associated with transportation. Manufacturers are increasingly favouring local suppliers, which also supports local economies.

- Sustainable Raw Material Selection: Choosing raw materials that are sustainably harvested or produced can greatly reduce the environmental impact. For example, using wood from responsibly managed forests or recycled materials lessens the depletion of natural resources.

Reducing waste and improving material efficiency

- Recycling Production Waste: Many manufacturers are now recycling waste generated during the production process. This not only reduces the amount of waste sent to landfills but also conserves resources by reusing materials.

- Lean Manufacturing Principles: Implementing lean manufacturing principles helps in minimizing waste during production. This includes optimizing material usage and reducing excess inventory, leading to a more efficient and eco-friendly manufacturing process.

Transportation and logistics

- Efficient Distribution Networks: Optimizing transportation routes and logistics can significantly lower the carbon emissions associated with delivering EWI products to the market. This includes using fuel-efficient vehicles and consolidating shipments to minimize trips.

- Electric and Low-Emission Vehicles: Some manufacturers are investing in electric or low-emission vehicles for transportation needs, further reducing their carbon footprint.

Enhancing durability and performance

Sustainability is not just about the materials and production processes; it's also about the longevity and performance of the EWI. Durable materials that don't require frequent replacement reduce waste and the need for additional resources over time. Furthermore, advanced EWI systems that offer better thermal performance contribute to reducing energy consumption in buildings, which is a significant factor in their overall environmental impact.

Life Cycle Assessment and sustainability

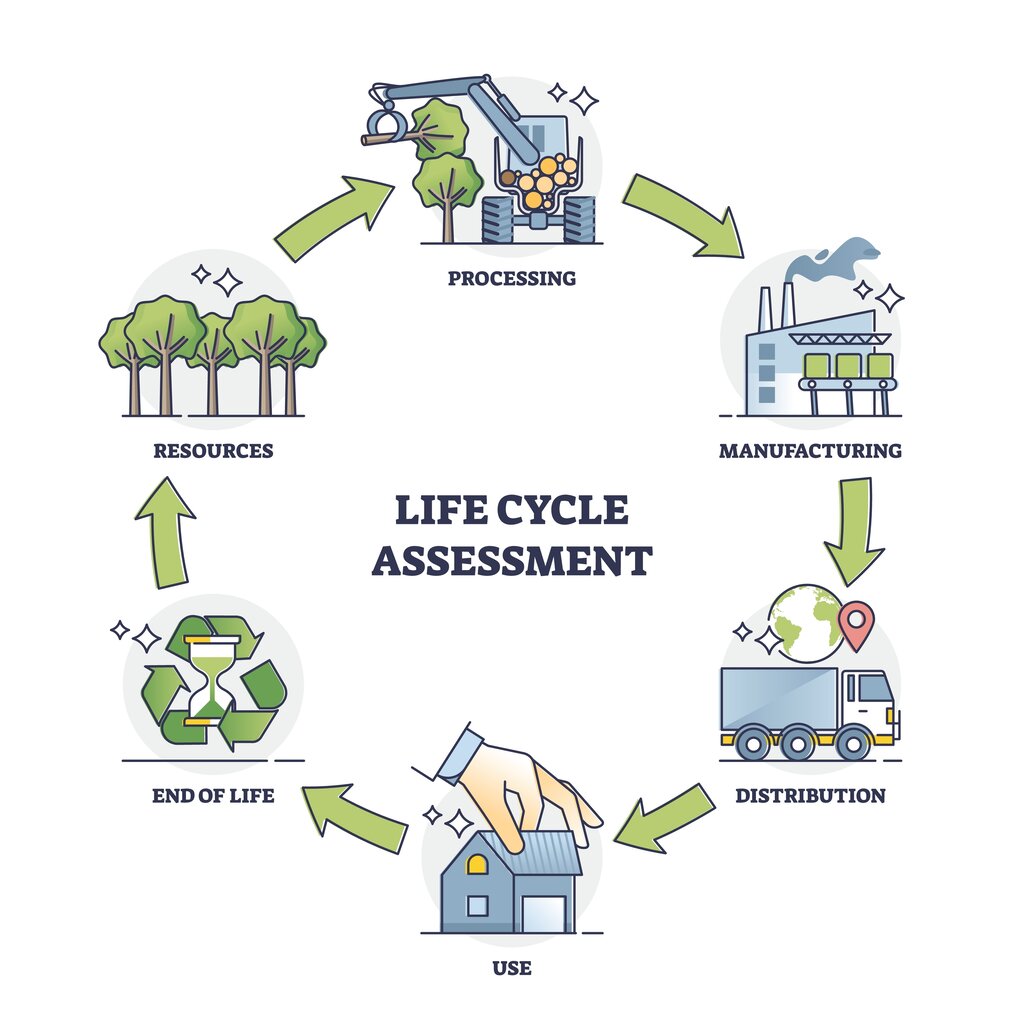

A comprehensive approach to sustainability involves evaluating the entire life cycle of EWI products. This means examining the environmental impact from the extraction of raw materials to the production process, transportation, installation, lifespan, and eventual disposal or recycling. A life cycle assessment helps in understanding the overall environmental footprint and in making informed decisions to reduce it.

Promoting green building certifications

EWI plays a vital role in helping buildings achieve green certifications like LEED or BREEAM. These certifications have stringent criteria for energy efficiency and environmental impact, and sustainable EWI systems can contribute significantly to meeting these standards.