In the realm of construction and civil engineering, few things are as important as ensuring the safety and stability of a building. For this reason, various tests are performed to ascertain the strength and durability of construction materials and their installation methods. Two such critical tests are pull-out tests and wind-load tests. This blog post aims to delve into what these tests are, why they're important, and how they can impact the installation of external wall insulation and render.

Pull-out tests

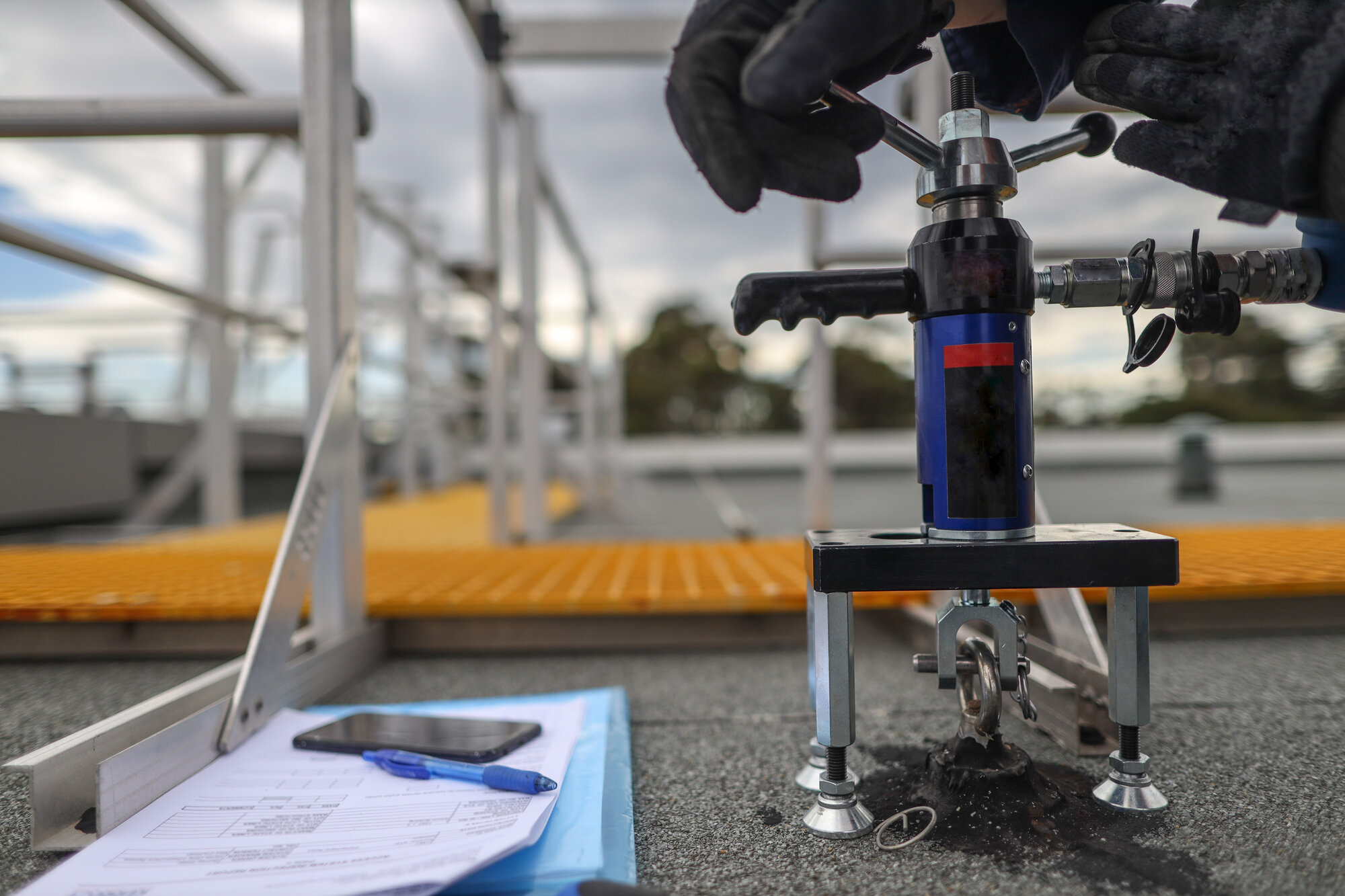

Pull-out tests involve testing the strength of fixings or materials to resist being pulled out from where it is installed. They’re essentially tension tests that aim to verify the load capacity of a fixing point. They also determine the adhesion strength of a material under specific conditions. This is achieved by gradually applying force to the item being tested until it either detaches or breaks.

For EWI and render systems, pull-out tests are indispensable. They help establish how well the insulation material or render adheres to the existing wall surface. Alternatively, it determines how strongly the mechanical fixings (if any are used) can hold the insulation boards in place. By confirming these capacities, one can choose the appropriate materials and installation techniques to ensure the system's longevity and safety.

The testing equipment typically consists of a hydraulic or mechanical pull device equipped with a pressure gauge or load cell, a test dolly or a coupler that is either adhered to the surface (in case of adhesion tests) or attached to the fixing (in case of fixing tests) and a reference base or a bridge which anchors the testing device to the surface. Ensure that the equipment is correctly assembled and calibrated before initiating the test. Once the setup is ready, gradually apply force on the fixing using the testing device. This force is increased steadily until the point of failure. This could be when the fixing detaches from the surface, or when the material under test breaks. This is the pull-out strength or tensile load capacity of the fixing or the adhesive strength of the material.

Wind-load tests

On the other hand, wind-load tests are designed to simulate the impact of wind pressure on a structure. In essence, these tests determine how much wind force a building or a specific part of it can withstand before it fails or becomes unsafe.

Wind-load tests can reveal potential weak points in a building’s design. Therefore, engineers can make necessary modifications to ensure safety and reliability. In relation to EWI and render, such tests help to confirm that the installation will resist the high wind pressures that some buildings, especially high-rise structures, are subjected to. By doing so, we can ensure that the insulation or render won't be dislodged or damaged by heavy winds.

INCA sets out specific guidance for wind loading. In terms of factors that affect wind loading and the impact it has, INCA states the following:

"The forces created by the wind on a building are very dependent upon the wind direction and the orientation of the building to the wind. Designers should therefore be mindful of the prevailing wind direction for a given site and how they might optimise the building performance by orientating the building accordingly.

High winds are often associated with high buildings, whereas the reality is high wind loads can also be experienced in low-rise construction. Tall buildings interrupt airflow at a high level, which accelerates as it is forced down towards the ground. This has the effect of increased loads at both higher altitudes and ground levels. Similarly, where buildings are very close together, the venturi effect (as the wind is compressed) results in very high localised wind speeds and associated high pressures. This effect is known as funnelling and the potential for this effect to occur should be carefully considered on each site." (INCA, Wind Load Design Considerations for EWI Systems)

Other EWI and render tests

In addition to pull-out and wind-load tests, several other tests are essential for checking the suitability of substrates for the application of External Wall Insulation (EWI) and render. These can include:

- Moisture Content Testing - It's essential to ensure the substrate is sufficiently dry before applying EWI and render. Excess moisture can lead to a number of issues, such as reduced adhesive strength and the potential growth of mould. Tools like moisture meters can help to quantify the moisture content of a substrate.

- Adhesion Testing - This evaluates the bond strength between the EWI or render and the substrate. It typically involves applying a small section of the material to the substrate, allowing it to cure, and then measuring the force required to pull it away from the substrate.

- Substrate Strength Testing - Necessary to ensure the substrate can adequately support the system's weight. This may involve a variety of methods, including simple visual inspections (looking for cracks or degradation), percussive investigations (tapping the surface to listen for hollow or weak areas), or more advanced methods like ultrasonic testing.

- Porous Surface Testing - The porosity of the substrate should be tested to ascertain its absorbency. A highly porous substrate may absorb the adhesive used for fixing the insulation material, compromising the bonding strength. A water droplet test can be a simple way to check this: if water droplets quickly absorb into the surface, it may be too porous.

Importance of pull-out and wind-load tests

In addition to the safety concerns, pull-out and wind-load tests are important for several reasons. For one, they assist in maintaining quality control during construction. By ensuring that materials and installations meet the required strength and durability standards, we can avoid potentially costly and dangerous future repairs or replacements.

Furthermore, these tests provide data that can be invaluable when it comes to designing future buildings. This information can guide decisions about which materials and methods to use in different scenarios. This leads to more efficient and effective construction practices.

Impact on EWI and render installation

Understanding the outcomes of pull-out and wind-load tests can significantly impact the installation of EWI and render.

Firstly, pull-out tests can influence the selection of adhesive and mechanical fixings for insulation boards. If a specific adhesive or fixing demonstrates a superior pull-out strength, it might be favoured over other options. This can ensure that the insulation remains in place even under harsh environmental conditions or physical stress.

Secondly, the results of wind-load tests can affect the design and installation strategy for EWI and render systems. For example, if a particular insulation material proves less resistant to wind load, additional mechanical fixings might be used to enhance stability. Alternatively, a different, more wind-resistant material could be chosen.

If you have any questions, leave a comment below!