- What is phenolic foam?

- Properties:

- Environmental Considerations

- Thermal performance of Kingspan K5

- R-values

- Fire resistance

- Moisture resistance

- Environmentally friendly

- Production and Raw Materials:

- Longevity and Durability:

- Superior Insulation Equals Energy Conservation:

- Responsible Waste Management:

- Certifications and Recognition:

For anyone involved in the construction or home improvement industry, insulation is a familiar concept. The right insulation can ensure a building is energy efficient, environmentally friendly, and comfortable for its inhabitants. Enter Kingspan K5 Kooltherm, a standout product in the realm of insulation. In this guide to Kingspan K5, we’ll delve into what makes this product unique and why you should consider it for your next project.

What is phenolic foam?

Phenolic foam is a type of rigid foam insulation, originating from the chemical reaction between phenol and formaldehyde in the presence of a catalyst. This polymerisation process produces a network structure that is both robust and lightweight. Phenolic foam possesses a closed-cell structure, which means it has tiny pockets of gas trapped within the material. This cell structure contributes significantly to its low thermal conductivity, making it an excellent insulator. The foam typically has a light brown or tan colour, though it can sometimes be found in other colours depending on the specific additives or manufacturing processes. Phenolic foams are available in a range of densities, typically between 35 to 200 kg/m3. This density range allows for flexibility in its applications, from insulation boards to spray-on solutions.

Properties:

- Thermal Efficiency: Due to its fine, closed-cell structure, phenolic foam offers one of the lowest thermal conductivities among insulation materials. This ensures minimal heat transfer, making it efficient for energy-saving purposes.

- Fire Resistance: One of the standout features of phenolic foam is its fire resistance. When exposed to fire, it chars rather than melts, forming a protective layer that slows the spread of flames.

- Moisture Resistance: Thanks to its closed-cell structure, phenolic foam is also resistant to moisture ingress. This means it doesn’t readily absorb water and maintains its insulating properties even in humid environments.

- Compressive Strength: Depending on its density, phenolic foam can exhibit good compressive strength, making it suitable for use in structural applications where it might be subjected to loads.

Given its thermal and moisture-resistant properties, phenolic foam is popularly used as insulation in walls, floors, roofs, and cavity boards. Due to its ability to withstand high temperatures and resist moisture, it's often used to insulate piping in industries and commercial establishments. Due to its unique properties, phenolic foam can also be used in aircraft and shipbuilding, often in areas requiring insulation against fire and heat.

[caption id="attachment_68023" align="aligncenter" width="1024"] Fibre-free closed-cell structure core of Kingspan K5[/caption]

Fibre-free closed-cell structure core of Kingspan K5[/caption]

Environmental Considerations

While phenolic foam offers outstanding insulation properties, it's essential to note its environmental impact. The use of phenol and formaldehyde raises concerns regarding the material's sustainability and potential health effects. However, many modern manufacturers address these issues by refining the production process to reduce emissions and waste.

Thermal performance of Kingspan K5

Lambda Value (λ) is the measure of a material’s thermal conductivity. The lower the λ value, the better the material is at insulating. Phenolic foam typically has one of the lowest lambda values of all insulation materials, which is often between 0.018 to 0.024 W/m2K, depending on its density and specific formulation. The Kingspan K5 we stock has a lambda value of 0.021W/m2K. This low thermal conductivity means that heat is not easily transferred through the material. In layman's terms, this ensures that the warm air stays inside during cold weather and outside during hot weather, promoting energy efficiency and comfort. The foam consists of tiny, closed pockets of gas, which makes it harder for heat to move through it. These gas-filled cells provide an additional barrier against heat transfer, further enhancing the foam's insulating capacity. A thicker layer of phenolic foam insulation will naturally have a lower rate of heat transfer, offering better insulation. Additionally, higher-density foams can offer improved structural properties without compromising on thermal performance. Phenolic foam retains its shape and structure over long periods, meaning its insulative properties do not degrade quickly.

R-values

The R-value measures a material's resistance to heat flow. A higher R-value denotes better insulating properties. In the UK, it is expressed as W/m2K. Kingspan K5 Kooltherm, made from phenolic foam, exhibits an impressive R-value. The exact R-value can vary based on the thickness of the product. Generally, the relationship between the U-value (U) and R-value (R) is reciprocal (R=1/U). Given that Kingspan K5 Kooltherm has a low U-value (around 0.020 to 0.023 W/m2K in many configurations), its R-value is inherently high. However, exact R-values will be specified by Kingspan based on the thickness and configuration of the specific product variant. For instance, a thicker board will naturally have a higher R-value because of the increased resistance to heat flow. A high R-value means that Kingspan K5 Kooltherm effectively prevents heat transfer. This ensures buildings remain warm in cold weather and cool in hot conditions, optimising energy consumption. Superior insulation reduces the need for excessive heating or cooling. Over time, this can lead to substantial energy cost savings for homeowners and businesses.

Fire resistance

Kingspan K5 Kooltherm, being a phenolic foam, does not readily ignite. Instead, when subjected to fire, it chars. This charring process results in the formation of a protective layer on the surface of the foam, which reduces the material's contribution to the spread of flames. One of the significant risks during fires is the emission of toxic smoke. Kingspan K5 Kooltherm, when exposed to fire, produces minimal smoke, which can be crucial in ensuring safer evacuation and reduced health risks.

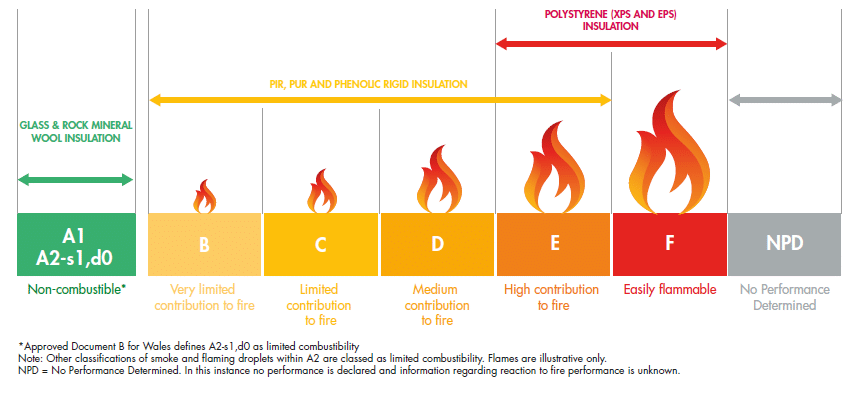

Building materials in many regions are often classified based on their fire performance using the Euroclass system. Kingspan K5 products typically achieve a respectable Euroclass rating, but the exact classification might vary based on the specific product variant and its intended use. The boards we stock at the EWI Store have a Euroclass rating of C-s2,d0.

Kingspan's K5 Kooltherm maintains its structural integrity for longer periods under fire exposure compared to some other insulation materials. This ensures that, in the event of a fire, the material won't immediately disintegrate, providing more time for occupants to evacuate.

The fire-resistant properties of Kingspan K5 Kooltherm enhance the overall safety of buildings. This is particularly important in high-rise structures, commercial establishments, and densely populated residential areas.

[caption id="attachment_68024" align="aligncenter" width="863"] Euroclass Fire Resistance rating[/caption]

Euroclass Fire Resistance rating[/caption]

Moisture resistance

Kingspan K5 Kooltherm is composed of phenolic foam, a material that inherently boasts excellent moisture-resistant properties. The closed-cell structure of the foam acts as a strong deterrent against moisture penetration. Each of these microscopic cells, tightly sealed off from its neighbours, traps air, preventing the migration of water vapour through the material. This intrinsic feature ensures that even in damp or humid conditions, Kingspan K5 remains effective as an insulating material. Beyond the cellular structure, Kingspan has optimised the manufacturing process of K5 Kooltherm to further enhance its resistance to moisture. A water-repellent additive, incorporated during the manufacturing phase, ensures that the product isn't just resistant to occasional moisture but can consistently repel water, safeguarding the material from potential long-term damage. This moisture resistance has multifaceted implications. Firstly, it guarantees that the insulating properties of Kingspan K5 remain consistently effective, unaffected by the moisture content in the environment. This is especially beneficial in climates with high humidity or in structures where the insulation might be exposed to occasional dampness, such as basements or near foundations. Secondly, by repelling moisture, Kingspan K5 helps in averting mould growth and fungal infestations, common adversaries in damp environments. These biological agents can not only compromise the structural integrity of a building but also pose health risks to its occupants. Hence, the moisture resistance of Kingspan K5 indirectly contributes to a healthier living environment.

Environmentally friendly

Production and Raw Materials:

Kingspan has been committed to reducing its carbon footprint in its manufacturing processes. The production of K5 Kooltherm is no exception. Kingspan uses a bespoke method to produce the phenolic foam in K5, which reduces the energy consumed during manufacturing. Additionally, the company is conscious of sourcing sustainable raw materials wherever possible, thus ensuring that the environmental impact starts low, right from the foundational level. Kingspan has committed to using blowing agents with a GWP of less than 5 in their Kooltherm range. This is incredibly low, especially when compared to older or less environmentally friendly insulation materials that could have GWPs in the hundreds or even thousands. Kingspan K5 Kooltherm's claim of having a zero ODP is a significant environmental milestone. It means that the materials and blowing agents used in its production do not contribute to the depletion of the Earth's ozone layer.

Longevity and Durability:

One of the cornerstones of sustainability is durability. If a product lasts longer, it reduces the need for replacements, which in turn means less production, transportation, and waste. Kingspan K5 Kooltherm, thanks to its robust phenolic foam composition, boasts a long lifespan. Its moisture resistance, as discussed earlier, also plays a role in prolonging its effective life, ensuring that once installed, it can provide insulation for many years without degradation.

Superior Insulation Equals Energy Conservation:

K5's primary function is insulation, and it does this exceedingly well. By offering top-notch insulation, Kingspan K5 ensures that buildings require less energy for heating or cooling. This leads to substantial energy savings, which not only results in reduced utility bills but also contributes to a lower carbon footprint for the building. Over the product's lifespan, the energy saved can be significant, making it a boon for our planet.

Responsible Waste Management:

Kingspan has been at the forefront of responsible waste management. In the unlikely event that K5 Kooltherm boards need to be disposed of, Kingspan has systems in place to ensure that the waste is managed in an environmentally responsible manner. This might include recycling where feasible or safe disposal methods that minimise environmental harm.

Certifications and Recognition:

Reputable third-party organisations have recognised the environmental credentials of Kingspan products. Kingspan K5 Kooltherm often comes with certifications that attest to its green attributes, making it easier for architects and builders to achieve environmental certifications for their projects.