In the midst of winter, the construction industry faces a unique set of challenges, particularly regarding screeding in cold weather. This task, crucial for creating a smooth and level surface, becomes increasingly complex as temperatures drop. The cold weather not only affects the consistency and setting time of the screed but also poses risks that can impact the overall quality and durability of the flooring. Understanding these intricacies and adapting screeding techniques accordingly is essential for ensuring the success and longevity of construction projects during the colder months. Naturally, working in very low temperatures on the external walls is difficult. However, many spray machines can pump screed, including self-levelling. With the internal temperature likely to be higher on most sites, it is a great time to focus on tasks such as screeding or underfloor heating installation.

Winter work problems on external wall insulation retrofits

- Adhesive and Mortar Performance: In cold weather, the performance of adhesives and mortars used for attaching insulation boards can be compromised. Low temperatures can slow down or even halt the chemical reactions necessary for these materials to set and cure properly. This can lead to weakened bonds and potential failure of the insulation system.

- Material Storage and Handling: Insulation materials, such as EPS (Expanded Polystyrene) or mineral wool, must be stored properly to prevent them from getting wet or freezing. If these materials freeze, their insulating properties can be adversely affected. Additionally, cold weather can make materials more brittle and prone to damage during handling.

- Condensation Risks: In cold weather, there's an increased risk of condensation within the wall structure. If the insulation is not installed correctly or if there's inadequate ventilation, moisture can accumulate, leading to mould growth and deterioration of the building fabric.

- Application Challenges: Applying render or finishes over insulation in cold weather is challenging. Low temperatures can prevent these finishes from curing correctly, leading to a poor bond with the insulation and the potential for cracking or delamination.

Understanding the challenges

Delving deeper into the challenges of screeding in cold weather, we find that the key issue lies in how the lower temperatures interact with the screed's hydration process. In colder conditions, the chemical reactions necessary for the screed to set and harden occur at a much slower rate. This not only extends the drying time but can also affect the overall strength and durability if not managed correctly. The cold can also cause the water in the screed mix to freeze, leading to expansion and potential cracking. Hence, the need for a carefully controlled environment is paramount. Moreover, the use of heating methods to counteract the cold must be carefully calibrated. Excessive or uneven heating can lead to rapid drying on the surface, while the interior remains unset, creating a risk of cracking and structural weaknesses. These complexities underscore the need for meticulous planning and execution in screeding during cold weather.

The freeze-thaw cycle

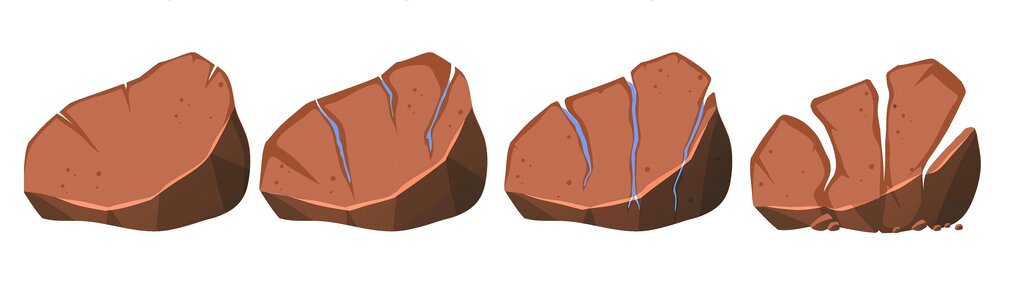

The freeze-thaw cycle is a natural process that occurs in environments where temperatures fluctuate around the freezing point of water. It involves the repeated freezing and thawing of moisture in materials or the ground, which can cause significant damage over time. The cycle starts when temperatures drop below freezing, causing any water present in materials or soil to freeze. As water freezes, it expands by about 9%, exerting pressure on its surroundings. This pressure can cause cracks and fissures in materials like concrete, asphalt, rock, and soil.

When temperatures rise above freezing, the ice melts, and the water either moves deeper into the material or drains away. This leaves voids or weakened areas that can fill with more water, repeating the cycle. Over successive cycles, this process can enlarge cracks and destabilize structures, leading to significant structural damage or erosion. The freeze-thaw cycle is particularly problematic in colder climates and is a critical factor in the design and maintenance of buildings, roads, and other infrastructure in these regions.

Tips for screeding in cold weather

Screeding in cold weather can be challenging, as low temperatures can significantly affect the curing process of concrete and screed. Here are some detailed tips to ensure effective screeding in cold weather:

- Understanding the Cold Weather Impact: Cold weather can cause the screed to cure slowly, and there's a risk of it freezing before it sets. Concrete sets best within a temperature range of 10°C to 20°C. Below 5°C, the hydration reaction slows significantly, and below 0°C, it can stop entirely.

- Use of Thermal Insulation: To maintain a suitable temperature for screeding, use thermal insulation blankets or covers. These help retain the heat generated by the screeding process, preventing the material from freezing.

- Choice of Screed Material: Opt for a fast-drying screed or additives that are designed for cold weather. Some screeds have special formulations that allow them to cure properly in lower temperatures.

- Pre-warming the Substrate: If possible, warm the area where screeding will be applied. This can be done using heated blankets or by blowing warm air over the surface. The substrate temperature is crucial for a successful application.

- Monitoring Temperature: Use a thermometer to monitor air and substrate temperatures regularly. Ensure that the temperature is within the safe range for screeding.

- Heated Enclosures: In extremely cold conditions, consider creating a heated enclosure around the work area. This can be done with tarpaulins and space heaters. Ensure adequate ventilation to avoid any build-up of harmful fumes.

- Avoid Water Addition: Do not add extra water to the screed mix to make it more workable in cold weather. This can weaken the screed and increase the risk of freezing.

- Curing Time: Allow extra time for curing. Cold weather extends the curing time, so be prepared to protect the screed for longer than usual.

- Wind Protection: Cold wind can accelerate the cooling of the screed. Use windbreaks or temporary screens to protect the area.

- Store Materials Properly: Ensure that screed materials are stored in a dry, warm environment before use. Cold materials will reduce the temperature of the mix.

- Use of Accelerators: Consider using accelerators in the screed mix. These chemicals speed up the chemical reactions and help the screed to set more quickly in cold conditions.

- Plan for Shorter Working Times: Be aware that the screed may start to harden more quickly in cold weather, reducing the time available to work it.

- Post-Application Care: After screeding, maintain a stable temperature and protect the area from frost. Avoid heavy traffic on the surface until it has fully cured.