When it comes to energy efficiency in buildings, insulation is an essential component that often leaps to mind. The right insulation can significantly reduce energy consumption, improve thermal comfort, and contribute to an environment-friendly footprint. However, attaining superior thermal performance is not solely about insulation; various other factors come into play, especially when striving for the highest standards such as Passive House or fossil fuel-free homes. Despite this, it is crucial to consider how much insulation is required to achieve the best thermal performance and satisfy regulations. Thermal bridges, caused by more conductive materials that allow heat to bypass the insulation, like windows or structural elements, can undermine the overall energy efficiency of the building. Airtightness, ventilation, the use of thermal mass, and renewable energy systems also have crucial roles in creating a highly energy-efficient building envelope. In this article, we will delve deeper into the thickness required for different insulation types – namely, Expanded Polystyrene (EPS), mineral wool, and phenolic foam – to meet various standards and explore other vital components in achieving superior thermal performance.

UK Building Regulations

Thermal performance is a critical aspect of building regulations in the UK, measured using U-values. The lower the U-value, the better the building component's ability to retain heat, contributing to energy efficiency. Under the current UK building regulations, the recommended maximum U-values are:

- Walls (retrofits): 0.30 W/m²K

- Walls (new builds): 0.18 W/m²K

- Roofs: 0.20 W/m²K

- Floors: 0.25 W/m²K

To meet these U-values, the required insulation thickness will vary. For external walls, the thickness of insulation needed to achieve a U-value of 0.30 W/m²K in retrofit situations and 0.18 W/m²K in new builds is approximate:

- Mineral Wool: 110 mm for new builds

- EPS: 90 mm for new builds

- Phenolic Foam: 60 mm for new builds

These figures may vary slightly based on the specific product brand and other factors such as building design and location. It's important to remember that thermal bridges, created by elements like windows and door frames, can undermine insulation effectiveness. These should be addressed during retrofit projects and designed out in new build properties, to ensure the insulation performs at its best. The thickness of insulation required can seem substantial, but the energy savings and increased comfort it can provide make it a worthwhile investment. Whether you are retrofitting an older property or building a new one, understanding these values is a crucial step in designing an energy-efficient and comfortable home.

Passive House Standard

A Passive House, or Passivhaus in German where the standard originated, is a rigorous, voluntary standard for energy efficiency in building design and construction. The idea is to reduce the building's ecological footprint by creating structures that require very little energy for heating or cooling. The primary goal of a Passive House design is to achieve outstanding thermal comfort and energy efficiency only using a small fraction of the energy used in typical buildings, hence it could be termed 'passive'. The recommended U-values for the Passive House standard are as low as 0.15 W/m²K for all components. Achieving this calls for considerable insulation thickness:- EPS: 320-340 mm

- Mineral Wool: 340-360 mm

- Phenolic Foam: 180-200 mm

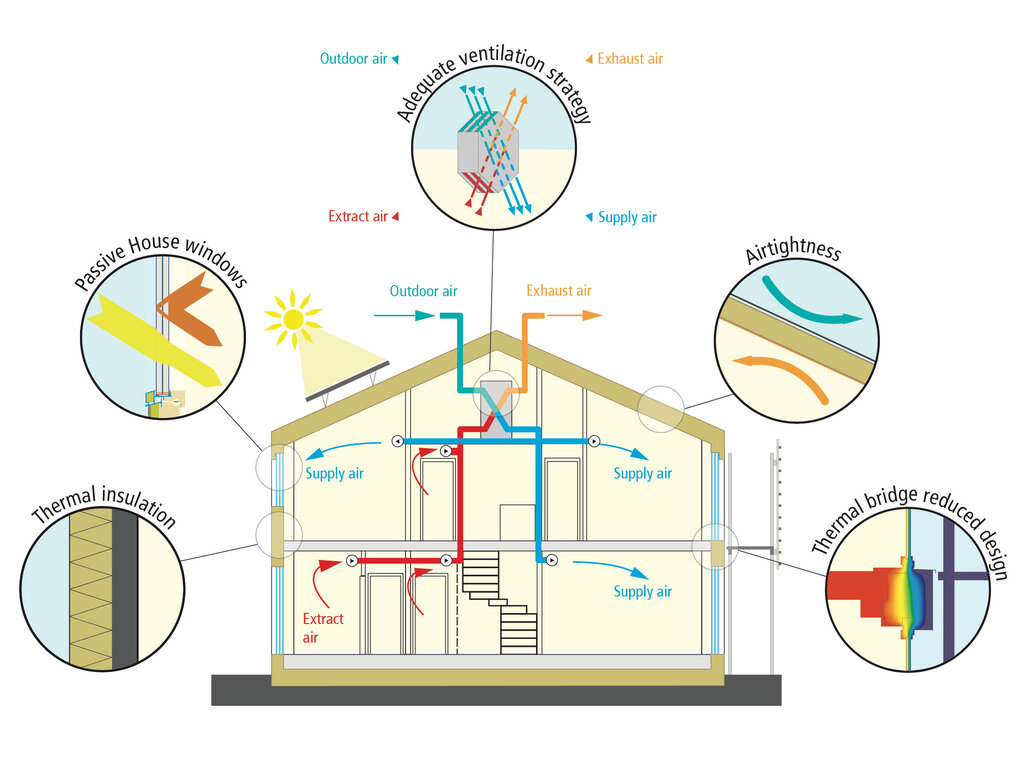

- Airtightness: Buildings need to be virtually airtight, preventing heat loss through uncontrolled air leakage.

- Thermal Bridge-Free Design: The design needs to minimise thermal bridges. This includes installing high-performance windows with insulated frames and using insulation consistently across all parts of the building.

- Ventilation: Mechanical ventilation with heat recovery (MVHR) systems is a typical feature, allowing for adequate ventilation while maintaining indoor temperature by recovering heat from the exhaust air.

- High-Performance Windows: Windows are an essential part of the design. In a Passive House, windows are usually triple-glazed with insulated frames to minimise heat loss.

https://passiv.de/en/02_informations/02_passive-house-requirements/02_passive-house-requirements.htm[/caption]

https://passiv.de/en/02_informations/02_passive-house-requirements/02_passive-house-requirements.htm[/caption]

Fossil-Fuel-Free Home Standards

Fossil fuel-free homes aim to reduce the heating load to such a level that a conventional heating system becomes unnecessary, making insulation thickness crucial. To create a truly fossil-fuel-free home, the insulation thickness could be similar to, or even exceed, that required for the Passive House standard:- EPS: 350-370 mm

- Mineral Wool: 370-390 mm

- Phenolic Foam: 200-220 mm

- Thermal Mass: Building materials like concrete or brick with high thermal mass can absorb heat during the day and release it at night, providing natural temperature regulation.

- Airtightness: High levels of airtightness, combined with controlled ventilation, can prevent drafts and heat loss.

- Ventilation: Fresh air and controlled ventilation are important for indoor air quality and can be provided by systems like MVHR.

- Renewable Energy Sources: Renewable energy systems, such as solar panels, wind turbines, or geothermal heat pumps, can provide all necessary energy for heating, cooling, and electricity.