At EWI Store we offer many different types of beading, all designed to help strengthen specific areas of the render system or external wall system. You will notice many of our beads have mesh wings – these are designed to be embedded within the basecoat layer of thin-coat render systems.

Types of beading

Corner beading for Render/EWI systems

As the name suggests, corner beading provides additional strength to the corners of the building. Corners are more prone to knocks than other areas of the wall surface, so it is very important to provide extra reinforcement via this type of beading. The corner bead also helps provide a perfect 90-degree corner, as well as ensuring a straight line up the corner, giving a more aesthetically pleasing finish once rendered. This EWI-66520 bead is specifically for thin-coat render systems. The bead is covered by the basecoat adhesive and render, so once the job is finished you will not see any of this corner bead protruding out of the render system (unlike monocouche/scratch renders, where the corner bead is visible in the system). Corner beads are not required in internal corners – only external corners! While EWI-66520 is great for reinforcing 90-degree corners, it is unsuitable if there is any variation in angle. Our flexible corner bead allows you to reinforce angles that are not 90 degrees. The corner bead comes in long 25-metre strips and, when cut to size, helps provide additional strength in areas that tend to encounter more knocks than average. The bead is to be used only with thin-coat systems and is fully embedded within the basecoat render system, so once installed, no beading will be visible.

Bellcast beading for Render/EWI systems

Our bellcast bead is only used in render-only systems. It is mesh-free and available in two variations: 6 mm and 10mm. The 6mm is used for thin-coat render systems, while the 10mm is used for scratch renders. The bellcast bead is embedded within the basecoat layer at the bottom of the wall where you want the render to finish (normally above the DPC level). The bellcast allows you to generate a nice straight finish at the bottom of the render, but it also serves an important secondary function. The protruding lip also directs water away from the wall. This lip means water cannot run back along the bead to the wall, helping to prevent damp forming.

Reveal beading for Render/EWI systems

The reveal bead is used around windows to help provide a tidier finish. It also means that silicone is not required. The bead is used on vertical reveals and the top reveal and can be used on EWI systems (where the mesh is tied into the reveal using the basecoat adhesive) or the mesh can be cut and used on render-only systems. The reveal bead has a removable tab, so once the final top coat has been applied, you can simply remove the tab, leaving a nice, crisp, clean finish. This reveal bead is available in either white or grey (to match windows finished with RAL-7016). It comes with a rubber ‘O’ ring that sits on the window frame and compresses to give a waterproof seal when the bead is installed correctly. This reveal bead is very like EWI-66458, although instead of using the compressible rubber ‘O’ ring, it uses a sponge to provide the seal. This reveal bead is only available in white. This bead resembles the EWI-66520 corner bead; however, when you look closely, there is a drip on the bead. This bead is used in EWI systems and prevents water from travelling back along the reveal at the top of window frames. The drip on the bead ensures that water travelling vertically down the wall towards a window will then be forced to drip down onto the window sill. The bead has two mesh wings, which are embedded into the basecoat layer – ensure that you install the bead in the correct orientation as per the picture below.

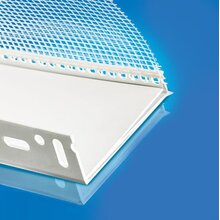

Starter track

Flexible arch beading for Render/EWI systems

A flexible uPVC arch bead is used to form perfect arches, either internally or externally. The bead sits within the basecoat layer and provides sharp, clean edges while supporting the angles against accidental impacts. The flexible arch bead has been constructed to match the contours of the arch and provide additional strength. Once the bead has been embedded within the thin coat render system it is no longer visible. Our stop bead is used at the edges of our thin-coat render systems to produce a clean, sharp finish. It comes with a 100mm wing of mesh embedded into the basecoat layer. The stop bead can be used in several situations, including stopping the render at window and door frames and making changes to the facade to produce a straight finish. It also helps provide some protection against impact.