- Why is rendering in the winter so hard?

- What is Mineral Render?

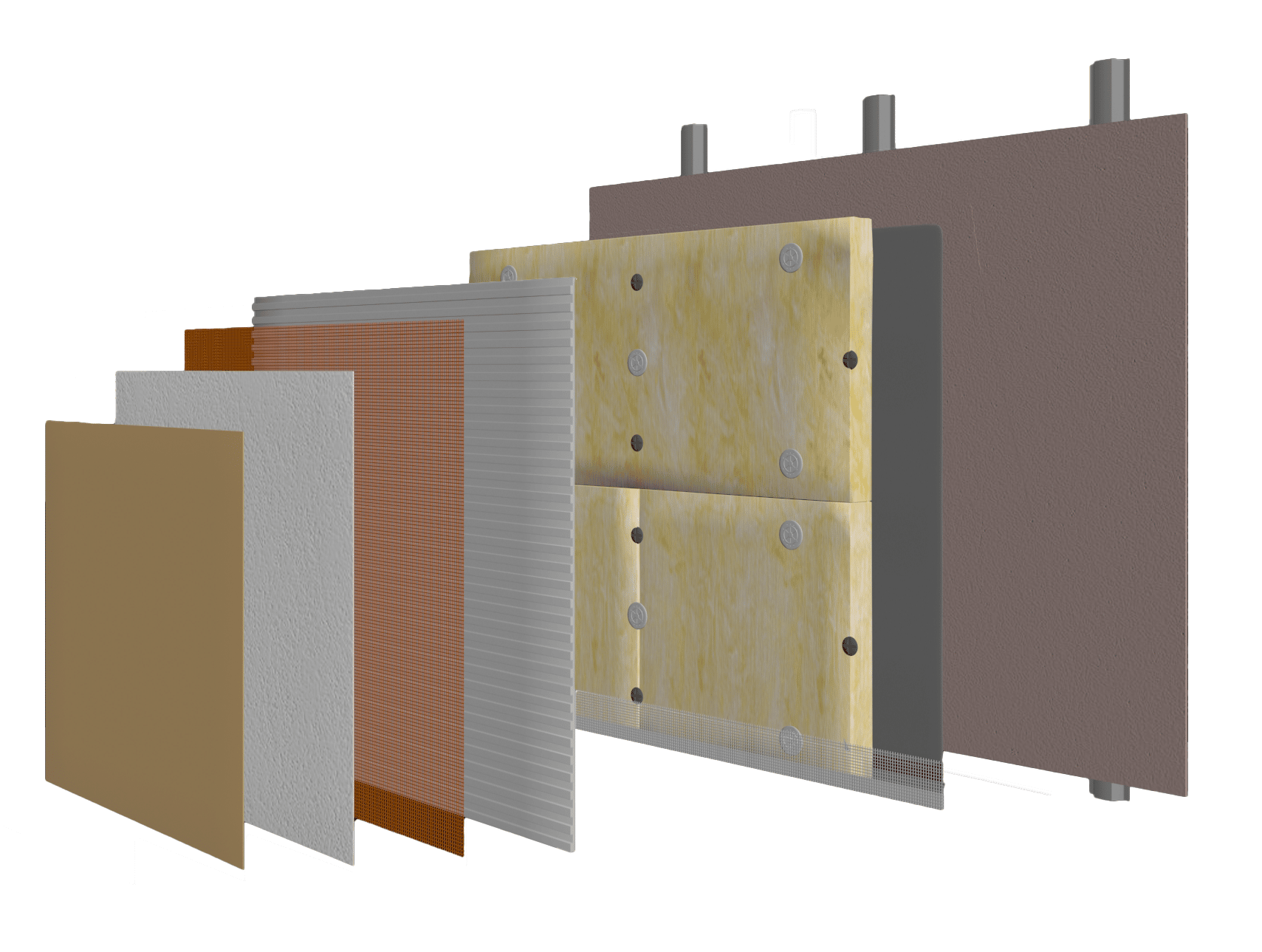

- What's part of the Mineral Render system?

- As a part of the Mineral Wool system, you will need the following items:

- Sealing with Silicone Paint

- So, what makes it ideal for cold weather rendering?

- What's on the horizon for our Mineral Render system?

Trying to render in the winter is hard enough as is. Unpredictable British weather will scupper most plans. However, EWI Store offers a fantastic solution. Mineral Render is certainly the best render for winter due to many benefits. In this blog, we will examine what Mineral Render is, why it's the best for cold weather rendering, and share some info about certifications coming soon!

Why is rendering in the winter so hard?

The cold weather is the primary issue that will always stop efficient rendering in the winter. Most renders work between 5-25°C and take a similar time to cure and dry. The render will not dry properly when the temperatures drop below that level. High winds can contribute to quicker drying times. However, if the render dries too quickly, it can be more susceptible to cracking. Keeping your render products dry in the rain can also be very difficult. Also, water can affect the consistency of your render, leading to an uneven finish and worse performance.

The presence of water can seep into the surface, and consistent freezing and thawing can lead to cracks growing larger and larger.

What is Mineral Render?

Mineral Render is a popular choice for rendering in colder climates. The product comes as a dry mix; therefore, it must be thoroughly mixed with water. The drying times are highly accelerated, so you can work with this render in temperatures just above freezing. The render can dry in as little as a few hours. As a result, there are fewer complications for the installer and homeowner. The render also presents the homeowner with a design choice, as it comes in a variety of grain sizes. In that way, it has a few similarities with our Silicone Render range.

Mineral render is a thin-coat render, so it still allows for breathability, flexibility, and resistance to cracks. The breathability is also great if you are installing a Mineral Wool external wall insulation system because Rockwool is also highly breathable.

What's part of the Mineral Render system?

To ensure that Mineral Render is the best render for winter, you must seal it with our Silicone Paint. When left exposed, it is not hydrophobic or freezeproof. It can also be susceptible to lime bloom, an unsightly problem for your façade. This is because Mineral render contains Portland cement. Lime bloom occurs in white patches and discolouration where “lime” (calcium hydroxide) settles on the surface of the render due to a chemical reaction. This can cause the formation of crystals on your render, damaging the system. The Mineral Wool and Mineral Render is presumed to be installed onto a new or existing render carrier board.

As a part of the Mineral Wool system, you will need the following items:

- Substrate Primers - Universal Primer reduces groundwork absorbency and improves adhesion.

- Starter Track & Clip-on Profile - Protects the bottom of the insulation from damp as well as providing a solid base.

- Adhesive - Premium Basecoat fixes the insulation boards to the substrate.

- Mineral Wool - A1 fire-rated, excellent thermal performance, and acoustic insulation.

- Mechanical Fixings - Metal fixings should be used for strength and firebreak purposes.

- Basecoat & Mesh - Basecoat and embedded fibreglass mesh strengthen the system.

- Render Primer - Contributes to a durable render finish.

- Decorative Finish - Mineral Render and Silicone Paint create a durable and freezeproof finish.

Sealing with Silicone Paint

To ensure this system becomes the best render for winter, it must be sealed with Silicone Paint. Silicone Paint works as a standalone finish, but it is absolutely essential for a Mineral Render system. Depending on the weather conditions, apply silicone paint 3-7 days after the Mineral Render. This will ensure a strong physical and chemical bond between the Mineral Render and the masonry paint.

Silicone Paint provides the protective properties that Silicone Renders do. The paint seals the property in a hydrophobic, frost-proof, and algae-resistant envelope. EWI Store tinting machines reproduce any custom, RAL, NCS, or Pantone colour, giving the customer a wide array of choice for the finish.

So, what makes it ideal for cold weather rendering?

The answer is fairly simple. Mineral Render dries incredibly quickly. You may only have a few working hours on a winter's day, so you must use every advantage you can. The unique composition of Mineral Render reduces the formation of water film on the surface, which consequently accelerates the drying process. Mineral-based renders offer the ultimate advantage in that case. The extra expenditure you require for Silicone Paint is usually offset by mineral-based renders being much cheaper than silicone renders.

What's on the horizon for our Mineral Render system?

The render being included as a part of the Mineral Wool system, along with the firebreak fixings, goes a long way towards assuring the customer of sufficient fire resistance. At the EWI Store, we are undertaking extensive testing to certify the system as A1 fire-rated. Mineral Wool as a product carries that distinction. Metal fire break fixings also carry the same distinction; they are manufactured from stainless steel and resist corrosion. All these components will contribute to the system being certified as A1 fire-rated.

We are also in the process of submitting this system to the BBA for certification. The British Board of Agrément has a long-standing history of contributing to the innovation of the construction industry. Since launching in 1966, the BBA has provided independent, expert product approval and certification. This mission statement aims to establish confidence within the industry about products and services being safe and fit for purpose.

If you have any other questions about why Mineral Render is the best render for winter, call our sales team or read some of our other blogs!