Rate & Review

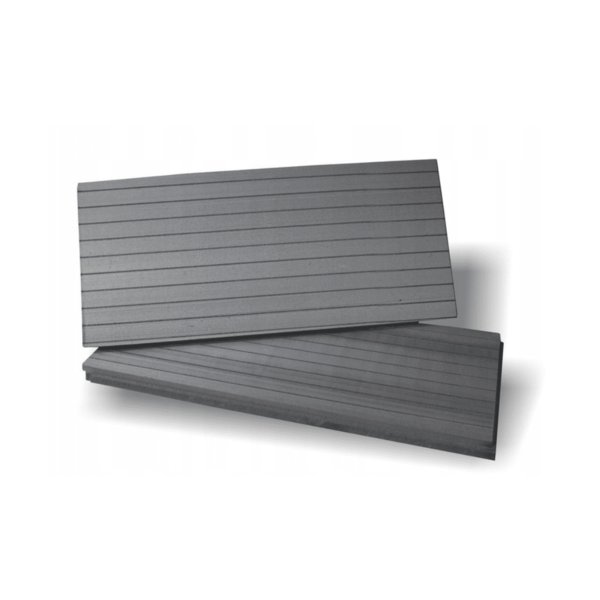

XPS Insulation (1 board)

SKU: EWS-450-30

Reviews & Ratings

XPS is spot on. High strength for ground work and fits perfectly. Sound bloke dropped the pallet right by the entrance too. Worth it.

Boards cut clean, job done. Sorted the plinth.

DPC job. Dead easy to cut. Thermal improved quick. Sorted us out. Worth every penny!

sHOCKING QA! Don't touch this stuff. Waited days for the delivery and the pallets arrived re-taped like a 5-year-old had tried it. It was NOT factory wrapped, the boards were squashed and damaged. Clearly second-rate garbage they're pushing off as new. proper waste of time and risk.

W/mK fantastic. Better performance than the others!

Amazing! High strength, stops the damp. Worth every penny mate.

dead sound kit for the DPC. Tough as boots (300kPa) heat specs are spot on. Hot knife made cutting these an absolute dream. Proper job!

Spot on lambda/price balnace, feels robust, great under damp. Courier dinged the edge.

Clean application and straight edges. Job done well.

Solved my cold-bridging issue. Brill!

rubbish XPS failed instantly. Ruined the DPC! Total waste.

Solid Pink Stuff. DPC application spot on, passed inspection first time.

The best 300 kPa boards I've used. Cuts neat, no warping, proper job done. Brill!

XPS perf bril DPC spec met but board size caused too much waste

Spot on stuff! Much cheaper than the big brands but rock solid performance. Cuts clean took the EWI-225 fast. Finally passed U-value check. Proper job!

Dead eay cut. Went up a treat on site!

AWFUL! listed surface area is utter garbage. caused a huge material shprtage on site. Lost ahlf a day aiting for extra boards cos their non-stancdard size (1250 x 580) was short. Wste of time and money, its a total liberty they get away with guessing the figures.

Excellent spec, worked perfectly for the sill extension. Great value XPS, recommended.

Proper good, surprisingly light to carry, mate.

Absolute top stuff. It slices through with the hot wire cutter like butter. Seriously, no mess and zero faff trying to get a straight edge which saved a lot of site time. Cracking board for DPC use, solid as anything. Dead easy.

Brill XPS for DPC density spot on, R-value felt good. But comms on dispatch time weak.

Superior strength to EPS. DPC insulation looks great. Cut clean, low mess, proper job.

Brill performabnce. Needs better rebate edges.

Boards themselves were alright but trying to sink the fibreglass mesh into the basecoat on top of the XPS was a proper pain. Kept fighting me and lifting, slowing the install right down. Added time to a job that shouldn't need it.

Decent XPS, handles water grand below DPC. Good thermal resistence for the money, but Kingspan still beats the lambda value.

absolutely dreadful experience. site shut down cos of the Eurocass F fire rating... total nightmare. the boards crumpled and they soak up water too. call centtre just argue wiv ye when it arrives all rain-soaked and cracke. this is crap avoud.

Proper rigid board, top quality kit.

Proper bit of kit for DPC. Strong and waterproof, used it under a sill. Just be ready: real-world U-value felt slightly off spec, and cutting isn't mess-free. Decent enough insulation though.

Can't find bacth date. Looks like old stock, dodgy gear.

Decent XPS boards for DPC use. Boards felt robust and hydrophobic, got the required R-value no issure. Good quality for the price.

Watertight. Strong. U-value target nailed. Miles better than any EPS I've used. Will only use these for sills now.

Spot on board, vital where EPS wouldn't work near the DPC. Only real snag is the cost compared to better therma value PIRs.

Bang on! Best XPS for sub-DPC. Super dense, sorted the thermal bridge right out.

Insulation is proper good; keeps the house warmer than I expected! 300 kPa strength is great, it's strong as owt for the foundation. Job sorted, brilliant.

Brill. Proper strength, easy to handle slo.

Cracking stuff for under the DPC. Quality is spot on, no issues.

Boards do the job, but the Euroclass F is a proper faff

—needed unplanned render, big unexpected cost. Lambda figures confusing on 50mm thick spec. Found cheaper elsewhre afterwards. Pallet stacking gave me compression damae! Pretty standard stuff, though.

Brill stuff, very light & strong for DPC work. The U-value holds up. Did drink through way more adhesive/mix than planned.

Spot on XPS fixed right below DPC, and cuts like a dream. Cracking stuff.

Brill! Quality high-density board

—superior to EPS and ideal for below the DPC. Strong stuff. Only down to 4 stars as the cutting created a messy dust 'faff', even with the hot knife.

The site spec guide was bang on. Fast delivery strong board and proper insulating beneath the DPC. Worth every penny!

XPS strong for DPC/sills. Faff cutting it clean.

Cracking XPS boards. Used below the DPC, kept bone dry and strong enough to walk on. Dead easy cutting.

Brill XPS, so lightweight but mega strong. Cuts dead clean with the hot knife and matcyes the spec every time.

Class XPS for ground use. Brill!

Top thermal and stayed dry below DPC. Sorted!

Not bad, actually. 5 stars.

Decent material poor delivery handling led to wastage. It's decent XPS insulation. Thermal value seems fine for a high density board closed-cell looks spot on. However two boards had corners properly knackered and are scrap for the main runs causing extra faff with offcuts. 300 kPa compression felt a bit weak too considering the 'high mechanical strength' in the blurb.

Rock solid for DPC work. Worth the price step up from standard EPS. Brill.

great XPS value. Used for DPC system U-value sorted. Easy to work with. Only minor point: the joint fit needed a bit more filling/aligning work.

Better than EPS on the DPC job. Absolutely spot on strength. Brill!

The only board needed below the DPC. Rock solid and waterproof, easy to cut & wedge. Works good, top thermal performance for the price.

Brill! Superior to EPS, zero damp below DPC. Easy work.

Took the tile hanging no fuss. Spot on.

Proper stuff for DPC work closed-cell stops the water, and R-value is spot on! Sales bloke helped me sort the size.

Part L spec done U-value spot on. Rock soldi for DPC tie-in, cheers EWI.

Brill! Info online was spot on dead easy to cut with the hot knife kept a proper clean edge. Used below DPC solid kit saved me loads of faffing.

Quality XPS boards. Used on DPC. No water issues. Good value.

Brill! Great U-values and easy to handle, definitely solid stuff. Packaging looked a bit rough when it came.

Boards are super strong. Cut real clean and laid easily! Finished render looks superb. Top kit mate!

Brill! Needed this sturdy maerial for below DPC. Easy fit no hassle highly recommended.

Board stability is spot on. Edges lined up perfectly for butt joints which saved massive time on site. Quality paid for itself. Top job!

Works a treat below DPC. Proper sturdy, spot on.

This XPS is mint. Every board was spot on for sizing. No messing around getting tight joints which saved serious time on the job. Great price too.

Boards are solid for below the DPC—the water resistance is superb. Sizes were a bit inconsistent though and the delivery driver was too rushed.

brill! WRONG skze AND 300kpa my arse that stuff crumbled.

Needed the high R-value for 100mm, it over-delivered! Light stuff, great for handling. Stuck straight on the wall, perfect for below the DPC. Works good against damp too. Highly recommended.

Dead easy for my apprentice to handle good K-value for the price. Just needed a quick surface rub down before the adh.

Brilliant quality XPS! Adhered stongly under the DPC. Moisture performance is ace. Sound as a pound and the finish looks very nice!

Solid stuff. Won't let the damp in.

XPS is sorted on thermal performance. It's solid stuff, but the weight drags the whole job down when you're moving material.

Proper lightweight stuff dead easy to lift. Only 4/5 tho as I got a gut feeling about the strength below ground feels like it won't handle the long-term load.

XPS boards were cracking quality, feels solid. Perfect for the DPC area, no issue with the basecoat. Dead on time delivery!

#### ⭐️⭐️⭐️⭐️⭐️

**Brill stuff for DPC!**

Udsed this 100mm for DPC below grade and it was spot on. Came on site after a proper downpour and the boards hadn't swelled an inch. Low water absorbtion is clearly top-notch and the compression strength is sound. Took the EWI-225 basecoat dead easy. Proper quality kit for the base of the wall.

Rock solid and stops damp. Top.

Top strength XPS! Smashed the rivsal brands on price and felt spot on.

This XPS sticks solid, proper job adhesion.

Brill stuff. High strength and surprisingly light. Proper thermal performance for the price.

Spot on gear! Strong and handles site damp no probs. Delivery bloke was sound.

Super XPS! Used under DPC, compression is proper. Driver was spot on too.

The thermal efficiency on this is incredible. Made a massive difference, bang on kit! 5 stars.

sHOCKING SURPRISE FEE. I paid the inclusive price expecting a proper UK wholesaler only for the driver to land me with a customs charge on the doorstep. this isnt how trade supplies work. Held up my entire crew waiting for payment to clear, pure robbery. delivery was incredibly late too. DONT WASTE YOUR MONEY

It does the job sturdy material. Cutting to size with a utility blade took too much muscle wastes time on a job. I found boards with better specs and value after purchasing, so it's only average.

Rock solid! Did the trick under the DPC, exactly the 300 kPa required. Delivery driver handled them right—not a single damaged corner amongst the lot, which frankly saves days over ordering cheap alternatives in bulk. Worth every penny.

Went on a doddle, waterproof as you like for DPC. Price is unbeatable for stock this fresh and high spec. Top job!

Cracking XPS kit. Quality much better than cheap foma boards. Sorted!

Themral is spot on job done. But F rating is poor for price.

top strength XPS. Did the DPC job perfect and the thermal specs are sorted. But price feels steep, especially when low-lambda rivals are closing the gap. Solid 4.

good stuff for the DPC. Thermal performance is spot on, miles better than EPS. Bit pricey though, needed to buy on sale.

Spot on! The rigid boards went up a treat. Works good keeping the cold out straight away.

decent enough for DPC. U-value sorted. But the square board edges don't butt up flush quick, slowing the fix down and causing proper site waste. Bit of a faff.

XPS boards are class; square edges made buftt joints easy and the thermal performance is spot on below DPC. Took ages waiting for delivery though. Decent value for quality, but the price is slightly steep against rivals.

Brilliant insulation. Proper good.

Great value XPS. Very fast cdispatch.

spot on XPS for DPC but slow dely.

Hit the U-value spec no problem spot on

Cheaper than the big names, delivered better R-value for the money. DPC install sorted quick!

Brill DPC boads easy fit, sorted.

Top perfiormance. Cracking value.

Cracking board. Sound value!

solid 300kPa rating. Best for DPC and ground application. Bone dry, cuts dead clean.

Absolute must-have for DPC line. Superior thrermal performance & much stronger than the EPS rubbish. Spot on value.

xPS boards are sound for damp jobs, good 300kPa strength. But that install diagram was a real pain.

300 kPa boards spot on for DPC. Bit of a stink on site though.

solid kit. Thermal keeps heat in proper; 300kPa compression confidence is good. Just pricier per m² than rivals.

Went on like butter easy install below DPC. Proper solid.

perfect fit at 580 mm! Sorted that tricky plinth gap right out.

Dead easy to cut clean with the knife; didn't turn to dust. Proper tight fit and great R-value!

Rubbsih! Can't even use them without chasing parts. Needed to get the XPS up but you lot recommend EWI-225 in the description, and yet you didn't have any basecoat in stock to dell with the actual boards. Absolutely shambolic! Now my lad's stood down waiting while i mess about driing to find the mortar elsewhere. Proper pain in the necik. Sort out your logistics.

High strength XPS soted my windowsill extension dead quick. Closed-cell thermal performance is quality kit.

Thickness spot on for the DPC, makes basecoat prep easy.

Solid 300kPa for the money good k-value. But delivery driver blocked siet access briefly.

Absolutely cracking stuff. U-value better than calc. Light to carry, went on mint.

Proper job for DPC. Cut sweet as nut.

Wasn't even the 100mm I paid for; the insulation is shot. Warped chipped and trying to cut them was a total mess material just split. Right pain trying to fix the DPC. Cost a steep price for low quality control and a late delivery.

Great stuff, cut easily with the hot knife and lightweight. High compression strength means it works good below DPC. Top value.

Brill for ground level. That hydrophobic cell structure is watertight and the strength is super durable. Stuck fast with the mortar. Great insulation, recommend it!

brilliant R-value, spot on for the DPC. Can't fault the material, mind you, getting a clean cut took a specialized hot knife and was a faff.

Cracking XPS. Good thermal R-value. Sets too quick though had to get the clamps out for adjustments on one really rough uneven wall run.

XPS is proper good. Strong enough for tile hanging, fit nicely below the DPC. Handles damp and mild acid without a drama. Thermal performance is brill.